OPERATING INSTRUCTIONS

1.

IMPORTANT: Always operate the compressor at or below the MAXIMUM PRESSURE RATING of

the compressor. Please refer to Application & Specifications Sections of this manual for details.

2. Always observe the MAXIMUM DUTY CYCLE of the air compressor. Refer to Compressor

Applications and Specifications Sections of this manual for details. Operation exceeding

maximum pressure ratings and/or duty cycle will result in damage to the air compressor.

3. Your air compressor is equipped with an AUTOMATIC THERMAL OVERLOAD PROTECTOR. This

feature is designed to protect the air compressor from overheating and causing permanent

damage to your air compressor. The thermal overload protector will automatically cut power to

your air compressor should the internal operating temperature of the air compressor rise above

safe levels during excessive use.

4. Should at any time during use, your air compressor automatically shuts off; do not attempt to

restart it. Turn off power and allow unit to cool for about 30 minutes. This will allow the Thermal

Overload Protector to reset so you can safely resume use of the air compressor.

5. To prevent discharge of your vehicle’s battery, and enhance performance, keep the vehicle’s

engine running while using the compressor.

6. Only operate compressor in well ventilated areas.

7. The use of a relay is strongly recommended for installation of this compressor, but not included.

(40-amp relay value or higher per compressor recommended).

MAINTENANCE & REPAIRS

1. Periodically check all electrical and fittings connections. Clean and tighten as needed.

2. Periodically check all mounting screws. Tighten as needed.

3. Replace Air Filter Element periodically. Replacement frequency depends on operating frequency and

operating environment. For frequent use in dusty environment, we recommend that you replace air

filter element at least once a month.

4. Regularly clean dust and dirt from compressor cooling fins and motor housing.

5. Your air compressor is equipped with a permanently lubricated, maintenance-free motor. Never try to

lubricate the compressor.

6. All repairs should be performed by Manufacturer or Manufacturer’s Authorized Service Agencies only.

CAUTION:

Never touch the air compressor or fittings connected to the air compressor, with bare hands during

or immediately after use. The leader hose and fittings connected to leader hose will become very

HOT during and after use. If necessary, wear heat resistant gloves to handle fittings, air line, and

leader hose.

USER MANUAL

325C - 350C - 400C - 450C COMPRESSOR KIT

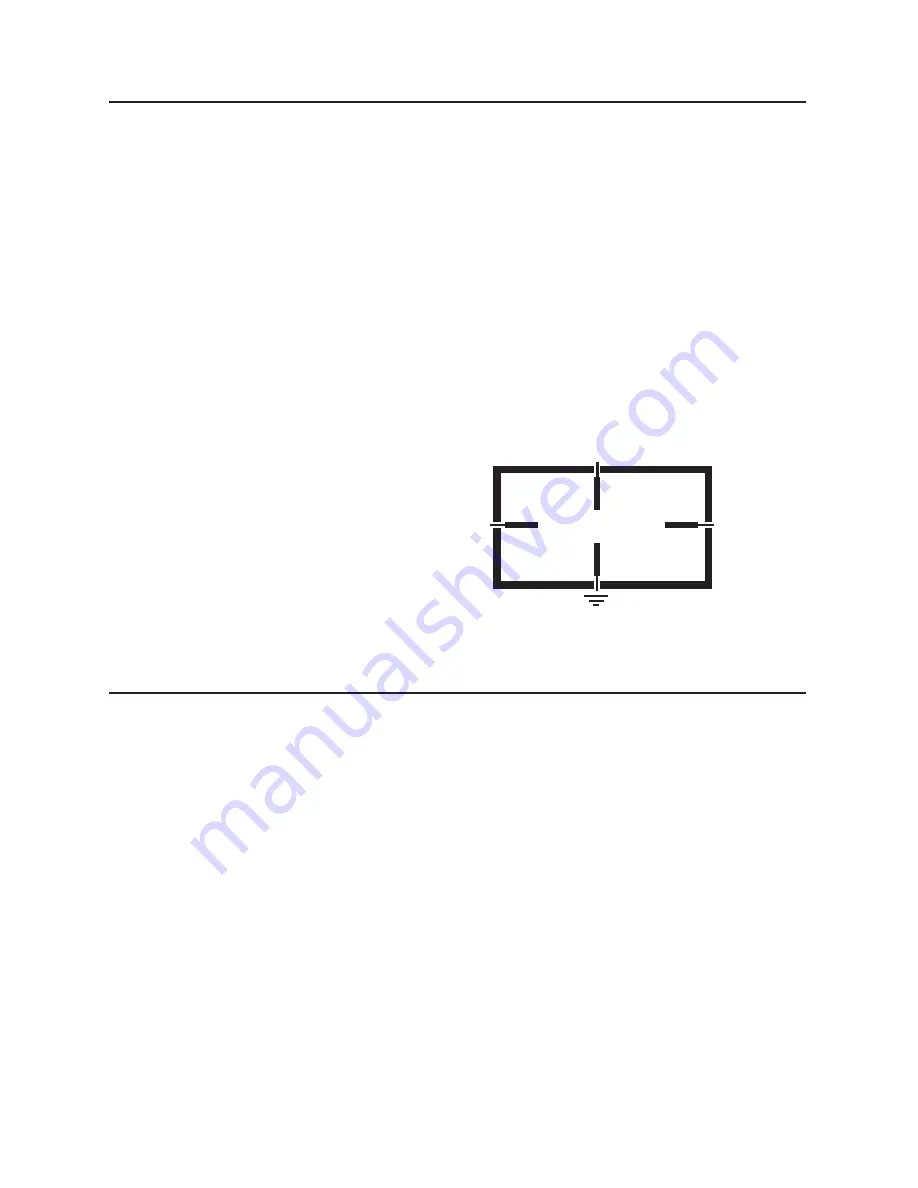

RELAY WIRING SCHEMATIC

Pressure Switch

86

Fused

12-Volt

30

To Ground

85

87

Compressor

(+) Lead