COMPRESSOR APPLICATION GUIDE

To ensure that you get the highest level of satisfaction from your compressor’s performance, refer to

information below:

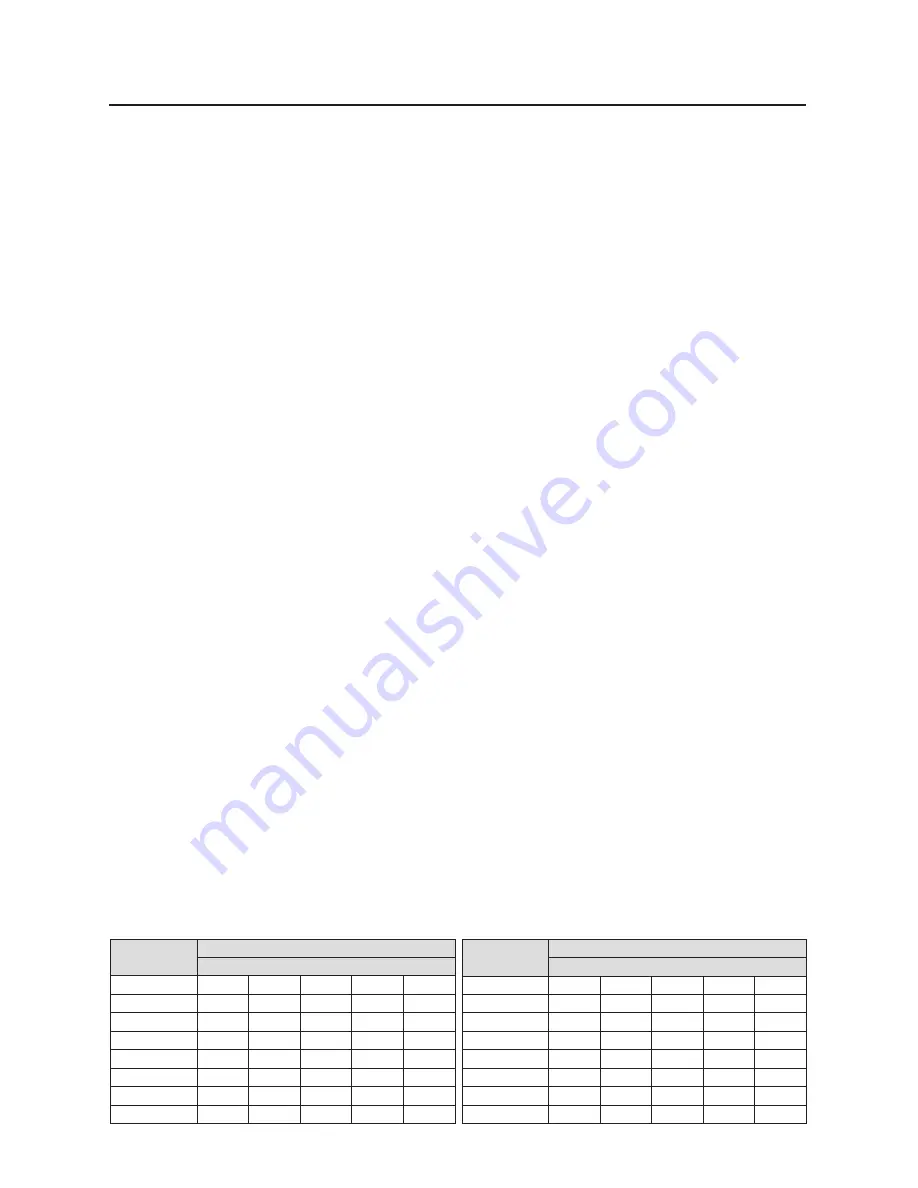

VIAIR COMPRESSOR REFERENCE CHART

COMPRESSOR SERIES

DUTY CYCLE

WORKING PRESSURE

100 SERIES

15%

130 PSI

200 SERIES

20%

150 PSI

215 SERIES

17%

150 PSI

225 SERIES

20%

150 PSI

265 SERIES

22%

150 PSI

275 SERIES

25%

150 PSI

280 SERIES

30%

150 PSI

325 SERIES

33%

150 PSI

350 SERIES

100%

150 PSI

380 SERIES

100%

200 PSI

400 SERIES

33%

150 PSI

450 SERIES

100%

150 PSI

490 SERIES

40%

150 PSI

490 SERIES

100%

150 PSI

ABOUT COMPRESSOR DUTY CYCLE:

Compressor Duty Cycle refers to amount of time a compressor can be operated in a given time

period, at 100 PSI and at a standard ambient temperature of 72°F. Duty Cycle is commonly

expressed in percentile as:

Compressor On Time/ (Compressor On Time + Off Time)%

As an example, a compressor that is rated for 25% duty cycle means that compressor can be

operated at:

100 PSI @ 72°F for 10 Minutes ON and 30 Minutes OFF

10 Min. On / (10 Min. On + 30 Min. Off) = 10 Min. / 40 Min.

=25% Duty Cycle

DUTY CYCLE REFERENCE CHART

DUTY CYCLE @100PSI / 72°F

MINUTES ON / OFF

15%

6 Min. On / 34 Min. Off

20%

8 Min. On / 32 Min. Off

25%

10 Min. On / 30 Min. Off

30%

13 Min. On / 30 Min. Off

33%

15 Min. On / 30 Min. Off

100%

Continuous Duty

ABOUT RATED WORKING PRESSURE:

To ensure trouble free service life of your compressor, always operate compressor within rated

working pressure of the compressor. Never use a pressure switch with a higher cut-off pressure

than compressor’s rated working pressure.

WIRE GAUGE GUIDE 12-VOLT:

WIRE GAUGE GUIDE 24-VOLT:

USER MANUAL

325C - 350C - 400C - 450C COMPRESSOR KIT

Amp Draw

Length of wire from battery to compressor

10

15

20

25

30

10

14

12

10

10

10

15

12

10

10

8

8

20

10

10

8

6

6

25

10

8

6

6

6

30

10

8

6

6

4

40

8

6

6

4

4

50

6

6

4

4

2

60

6

4

4

2

2

Amp Draw

Length of wire from battery to compressor

10

15

20

25

30

10

18

16

14

12

12

15

16

14

12

12

10

20

14

12

10

10

10

25

12

12

10

10

10

30

12

10

10

8

8

40

10

10

8

6

6

50

10

8

6

6

6

60

10

8

6

6

4