19

3.

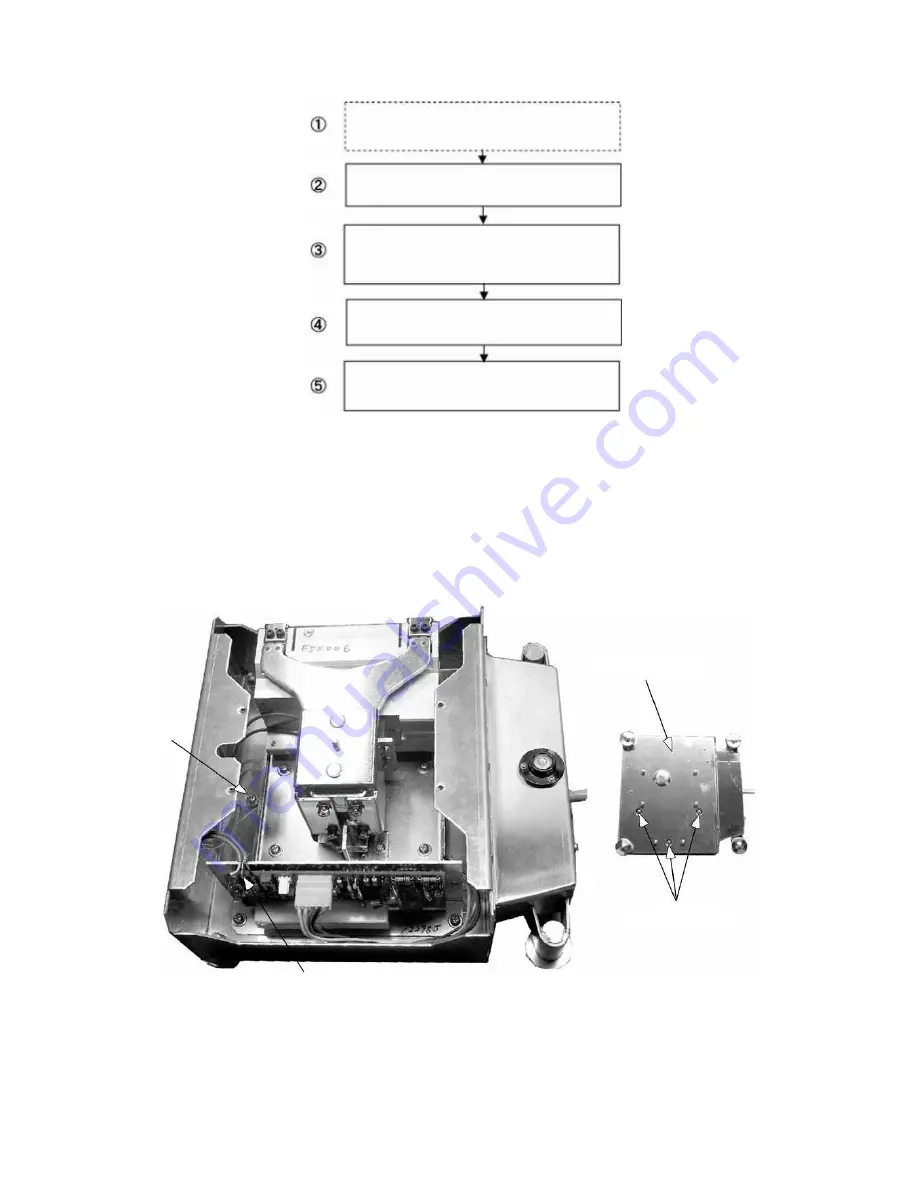

How to Remove the Mechanical Unit

(1) Remove the unit cover. (Refer to Figure 5-1)

(2) Remove the tuning fork assembly cord from the GZOSC-1 board. (Unsolder the cord.)

(3) Remove screw A with a Phillips-head screwdriver and remove the GZOSC-1 board.

(4) Remove the mechanical unit mounting nuts B (3) with a (7 mm) box nutdriver.

(5) Remove the mechanical unit from the chassis.

(Take care not to catch anything under the mechanical unit.)

(Figure 5-2)

The mechanical sensor assembly has

failed.

Replace the mechanical sensor assembly.

Enter the coefficient data.

(Enter data for the new mechanical unit.)

Span adjustment

Performance check

Back surface

Screw A

Nuts B

Soldered area