5

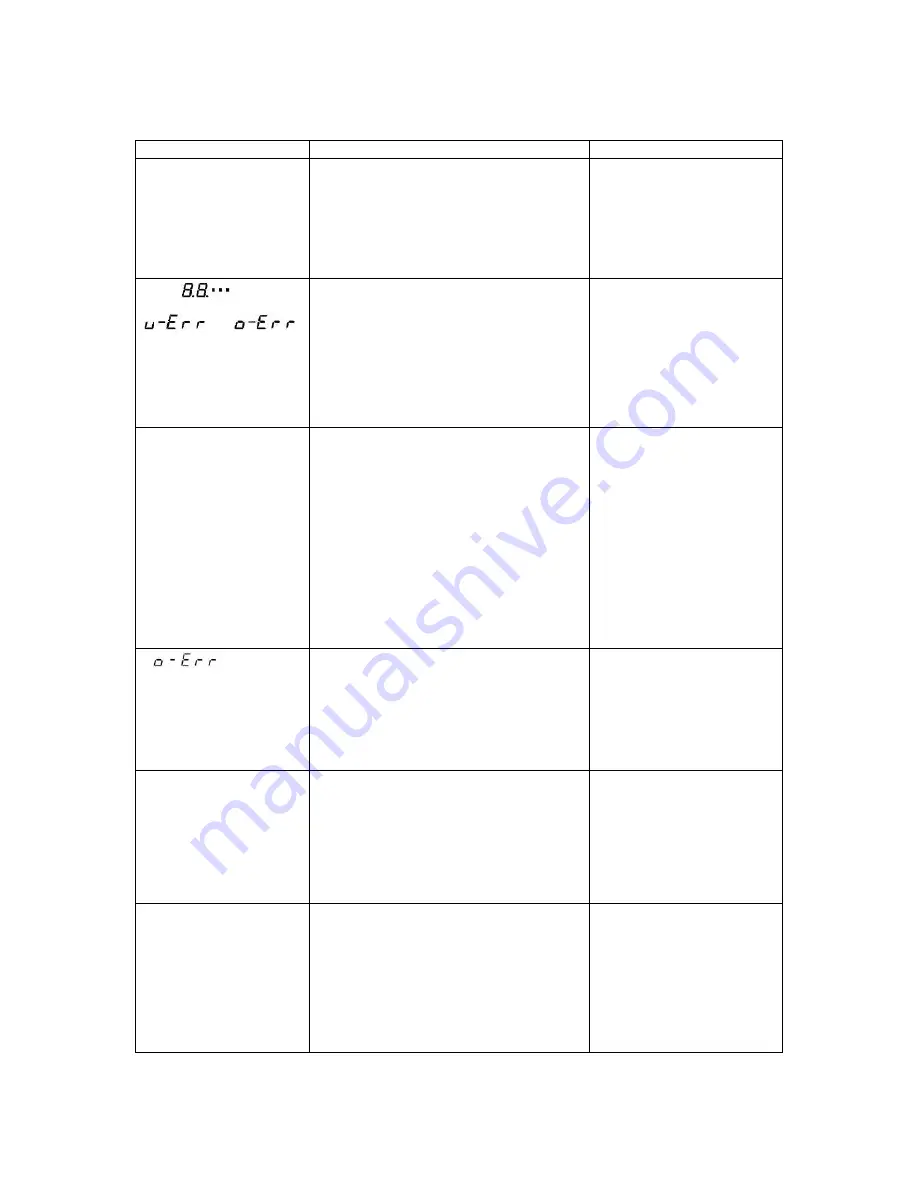

3-2 Quick Reference Guide for Troubleshooting

Symptoms

Probable causes

Remedies

1. The GZDSP-2 (GZBDSP-1) board has

failed.

1. Replace the GZDSP-2

(GZBDSP-1) board.

2. The power/battery box has failed.

2. Replace the power/battery

box.

3. The connection cables inside the balance

are incorrectly connected.

3. Check the connection of

the cables.

Noting is displayed.

4. The dry-cell batteries have run out

(battery box type).

4. Replace the dry-cell

batteries.

1. The wrong kind of pan is being used.

1. Check the pan.

2. The tuning fork assembly or mechanical

unit has failed.

2. Replace the tuning fork

assembly or mechanical

unit.

3. The GZDSP-2 (GZBDSP-1) board has

failed.

3. Replace the GZDSP-2

(GZBDSP-1) board.

4. The coefficient data is improperly set

(when the data was entered).

4. Check the coefficient data.

After “

” is

displayed,

“

” or “

”

is displayed.

5. The coefficient has changed due to static

electricity or noise.

5. Check the coefficient data.

1. Something is in contact with the stopper.

1. Check the mechanical

stopper.

2. Something is in contact with the

calibration weight unit.

2. Check the area around the

calibration weight unit.

3. Something is in contact with the pan (or

pan base).

3. Check the area around the

pan.

4. There is foreign matter in the balance.

4. Check the area around the

balance’s mechanical part.

5. The tuning fork assembly or mechanical

unit has failed.

5. Replace the tuning fork

assembly or mechanical

unit.

6. The balance is being affected by wind or

vibration, etc.

6. Check the area around the

balance.

The displayed value is

unstable.

Poor repeatability.

The zero point changes.

7. The GZOSC-1 board has failed.

7. Replace the GZOSC-1

board.

1. The tare is too heavy.

1. Check the tare weight.

2. The coefficient data is improperly set.

2. Check the coefficient data.

3. The coefficient has changed due to static

electricity or noise.

3. Check the coefficient data.

4. Span adjustment has been made with

erroneous weights.

4. Check the adjustment

weights.

“

” is displayed

before the weighing

capacity is reached.

5. Something is in contact with the

calibration weight unit.

5. Check the area around the

calibration weight unit.

1. The tuning fork assembly or mechanical

unit has failed.

1. Replace the tuning fork

assembly or mechanical

unit.

2. The GZDSP-2 (GZBDSP-1) board has

failed.

2. Replace the GZDSP-2

(GZBDSP-1) board.

3. The coefficient data is improperly set

(when the data was entered).

3. Check the coefficient data.

The span is significantly

incorrect.

4. The coefficient has changed due to static

electricity or noise.

4. Check the coefficient data.

1. The tuning fork assembly or mechanical

unit has failed.

1. Replace the tuning fork

assembly or mechanical

unit.

2. The coefficient data is improperly set.

2. Check the coefficient data.

3. The coefficient has changed due to static

electricity or noise.

3. Check the coefficient data.

4. Span adjustment has been made with

erroneous weights.

4. Check the adjustment

weights.

Poor linearity

5. The GZOSC-1 board has failed.

5. Replace the GZOSC-1

board.

(Table 3-1)