15

GT ULTRA ZERO AIR GENERATOR

USER MANUAL

www.vicidbs.com

Version 1.03.0000

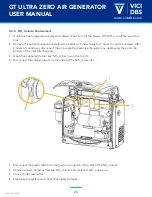

6.6 Connect Air Supply

The GT Ultra Zero Air generator requires a continuous supply of dry, oil-free compressed air with a pressure

between 4.5 (65.3 psig) and 10 barg (101.5 psig) for proper operation.

The air supply inlet pressure can be regulated with an adjustable forward pressure regulator, pre-set to 7 barg

(101.5 psig). The minimum allowable pressure is about 3 barg (43.5 psig); the maximum 10 barg (145 psig).

It is important that the air supply be maintained at room temperature and

dew point, and free of oils, hydrocarbons and particulates. If the compressed

air supply for the generator has excess moisture, oil or particulates, the inlet

filter may need premature replacement and the unit may be damaged. Install

extra coalescing and particulate filtration upstream from the unit if necessary.

6.7 Connect Output

• The output bulkhead of the GT Ultra Zero Air generator is located on the right side of the unit. It requires a

1/8” diameter fitting to attach the tubing or hose to the GC-detection system or analyzer air inlet port.

• In order to maintain the purity of the air from your GT Ultra Zero Air generator, stainless steel tubing or

instrument grade Teflon tubing should be used to connect the generator to the GC-detection system

or analyzer air inlet port. Copper tubing can also be used, but should be pre-cleaned or heated with a

propane torch while blowing nitrogen through it. All plastic hose should be instrument grade and free of

contaminants to avoid outgassing hydrocarbons or other pollutants over time.

•

Maximum outlet flow rate is 1.5 L/min with 7.5 barg (101.8 psig) inlet pressure and no external restrictions.

Actual outlet flow rate will depend on additional system pressure losses, if any.

WARNING: Maximum inlet pressure 10 barg (145 psig). Do not adjust the outlet

regulator on the unit without using an accurate pressure gauge (3-7 barg)

WARNING: The catalyst chamber can be contaminated

by high concentrations of lead, sulfur, phosphorous

compounds, heavy metals, chlorinated solvents and

chlorinated hydrocarbons. Extra care should be taken to

avoid introducing such compounds to the system. Any

contamination from oil, water or any of the substances

mentioned above will void the warranty.

WARNING: Do not use PVC or any other non-instrument grade plastic tubing

anywhere in your system. Many plastics will out-gas hydrocarbons and will

contaminate your purified air.

Lift and turn to

adjust pressure