ROLL CHANGING

VE460 roll grooving tools are designed with

rolls to accommodate several pipe sizes and

materials, which eliminates the need for

frequent roll changes.

When a different pipe size or material is required

for grooving, the upper and lower rolls must be

changed. For proper roll selection, refer to the

“Tool Rating and Roll Selection” section.

NOTICE

• Upper and lower rolls are matched

components and must not be intermixed.

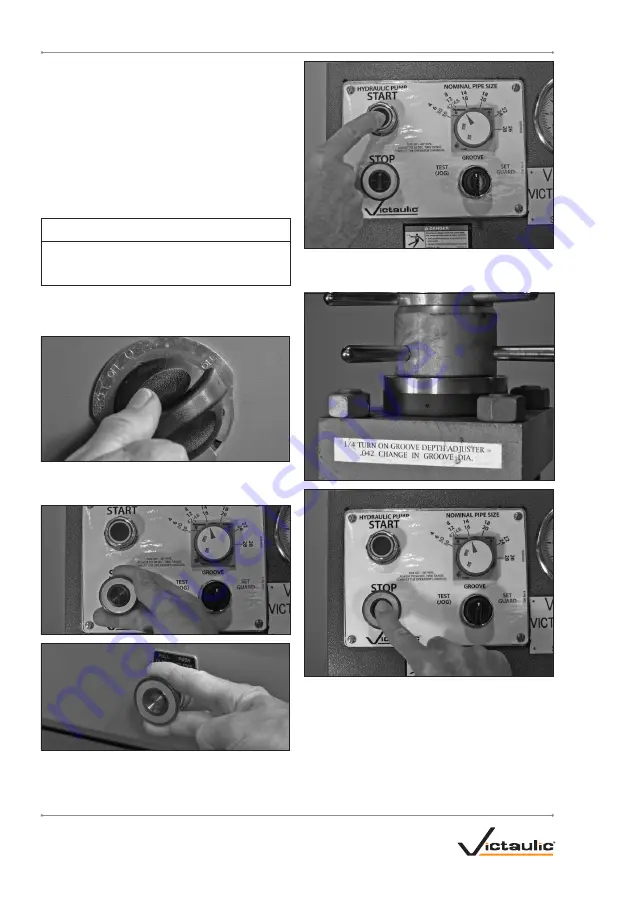

1.

Turn on the main power supply to the tool

(main breaker panel, knife switch, etc.).

2. Turn the power switch on the side of the

tool to the

“ON”

position.

3. Pull the

“STOP”

knob on the control panel

and the electrical enclosure to the out

position.

4. Push the

“HYDRAULIC PUMP START”

button.

5. Depress the safety foot switch. When

the groove diameter stop contacts the

hydraulic cylinder, push down (in) on

the red

“STOP”

knob on the control

panel. Release the safety foot switch, and

withdraw foot from switch.

TM-VE460_39

TM-VE460

OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY.

REV_A