MAINTENANCE

DANGER

• Always turn off the

main power supply to

the tool before making

any tool adjustments or

before performing any

maintenance.

Failure to follow this instruction could result

in death or serious personal injury.

This section provides information about keeping

tools in proper operating condition and guidance

for making repairs when it becomes necessary.

Preventive maintenance during operation will

pay for itself in repair and operating savings.

Replacement parts must be ordered from

Victaulic to ensure proper and safe operation of

the tool.

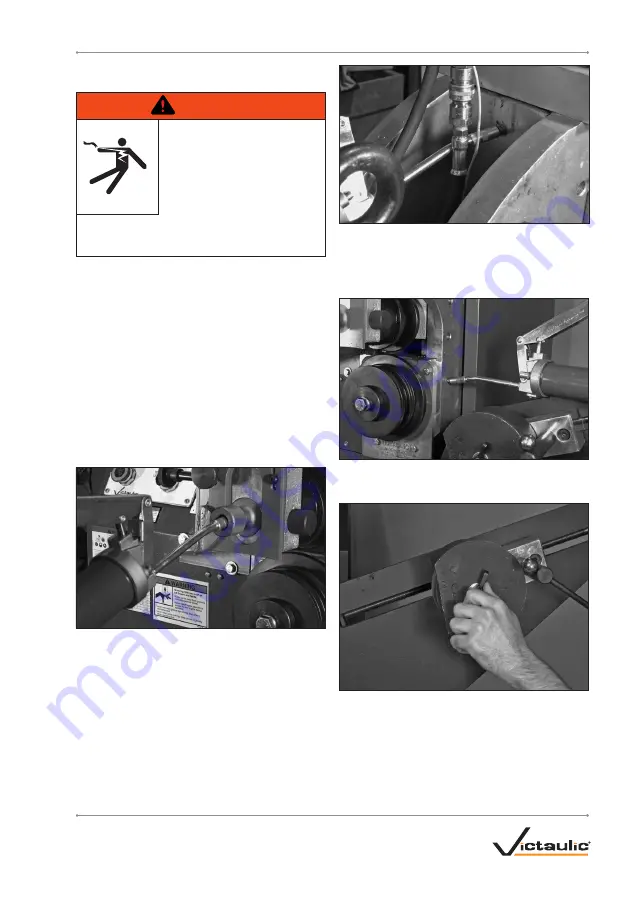

LUBRICATION

1.

After every 8 hours of operation, lubricate

the tool. Always lubricate the upper roll

bearings when rolls are changed.

2. Grease the upper shaft bearings every

time roll changes are made and after every

8 hours of operation. A grease fitting is

provided on the front of the upper shaft.

Refer to the applicable “Recommended

Lubricants” table for the proper grease.

3. Grease the slide gibs. The slide gib grease

fitting is located on the back of the slide

and is accessible when the tool hood is

open.

4. Grease the main shaft bearings through

the fitting located on the side of the tool.

5. Remove the stabilizer-roller-guard wing nut

and stabilizer roller guard.

TM-VE460_46

TM-VE460

OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY.

REV_A