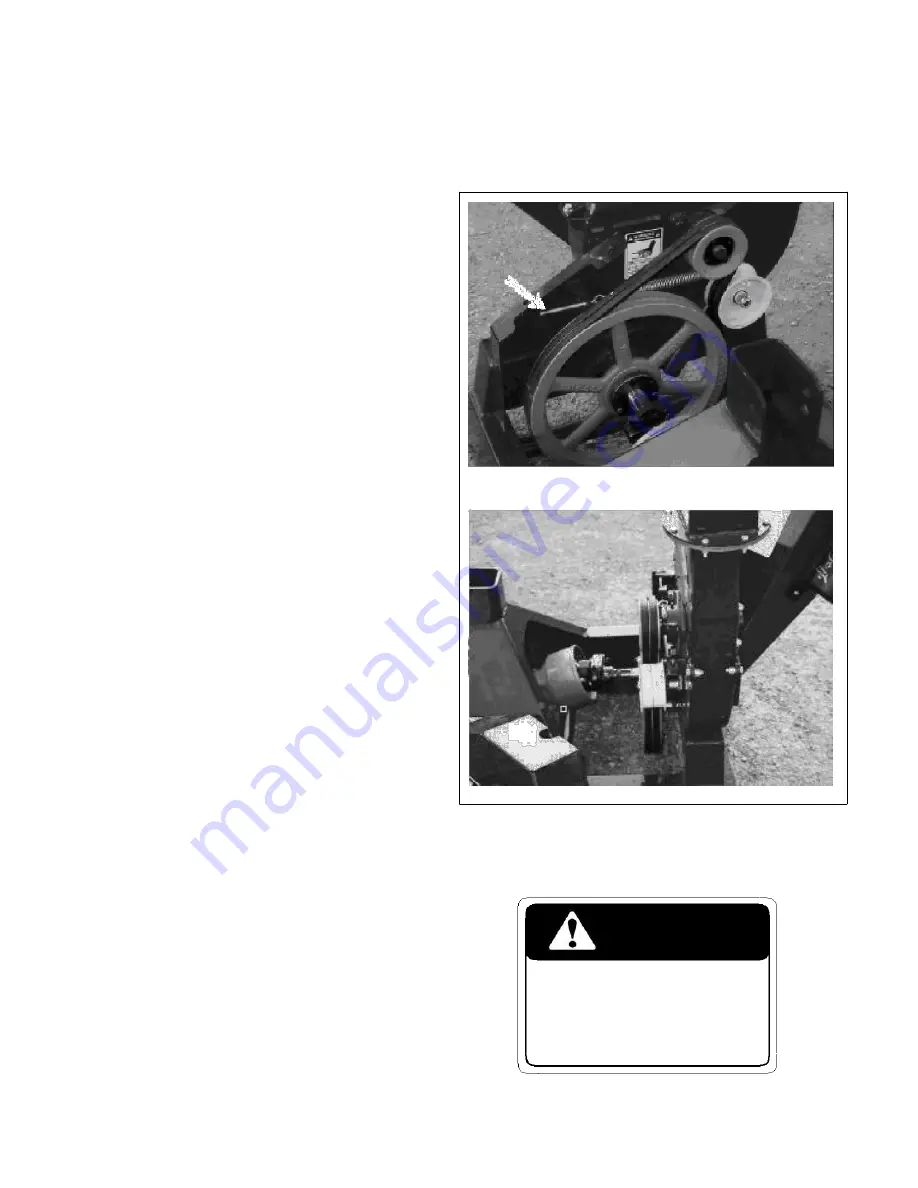

6.2.2 DRIVE BELT TENSION AND ALIGNMENT (Model BX32)

A set of V belts transmits rotational power to the

rotor. They must be kept properly tensioned and

the pulleys aligned to obtain the expected perfor-

mance and life.

To check the tension and alignment, follow

this procedure:

1.

Clear the area of bystanders, especially small

children.

2.

Turn machine off, stop engine, remove igni-

tion key and place in pocket and wait for all

moving parts to stop.

3.

Remove guard over belt.

4.

Push on the belt in the center of the span.

The belt should deflect approximately 1 inch

(25 mm) when pushed on with about 10 lbs.

force to be properly tensioned.

Adjusting Bolt

IMPORTANT

The belt should not slip when the

chipper is being used.

5.

To adjust belt tension:

Use the adjusting bolt on the spring-loaded

tensioning pulley to set the belt tension. The

bolt should not slip when the machine is be-

ing used with a normal load.

6.

To replace belt:

a. Move idler pulley to its loosest position.

Alignment

b. Replace belt.

Fig. 47

BELT DRIVE SYSTEM

c. Set pulley alignment.

d. Move idler pulley to set the belt tension.

e. Check frequently during the first 10 hours

and set belt tension as required.

7.

Lay a straight edge across the pulley faces to

check the alignment. Adjust alignment if pul-

ley faces vary more than 1/32 inch (.7 mm).

WARNING

Machine is shown with guard re-

moved or rotor cover opened for

illustrative purposes only. Do not

operate

machine

with

guard

removed or cover opened.

Summary of Contents for BX32

Page 1: ...Wood Chipper Operator s Manual BX42S BX72R Please read this manual prior to operation ...

Page 2: ...IMPORTANT READ THESE INSTRUCTIONS BEFORE INSTALLING AND USING THIS IMPLEMENT ...

Page 48: ...Annually 1 Clean machine BX32 BX42 BX62 Fig 45 MACHINE ...

Page 54: ...BX42S Wood Chipper ...

Page 57: ...BX72R ...

Page 62: ...67 03 05 7809 UCP208 inserted bearing with housing UCP208 68 03 02 6182 M14 locking nut M14 ...