Operator’s Manual Victory WC-8H

- Page 46 of 64 -

Version 2.0

is a sign that too much grease is applied and can deform the seal, causing an entryway for

contaminants.

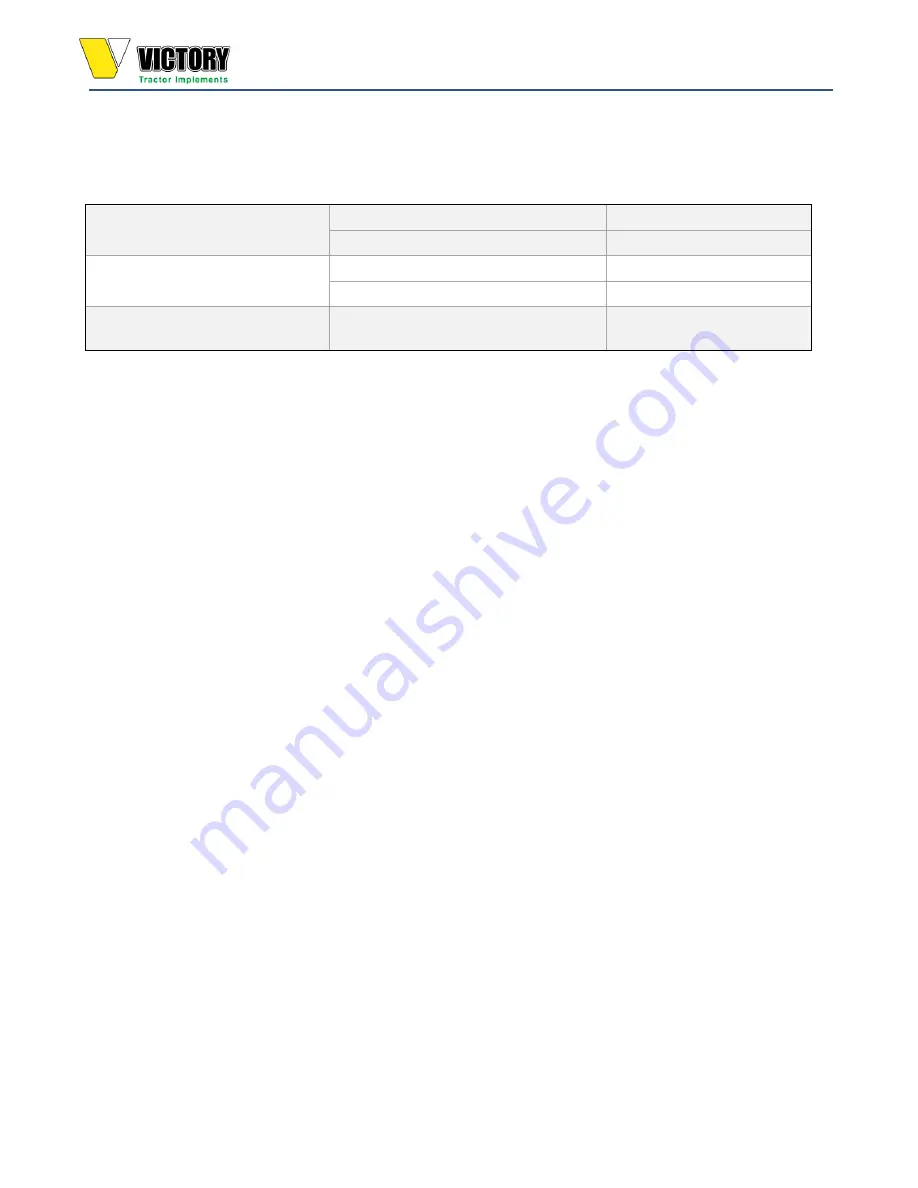

Follow the bearing lubrication schedule below for optimum performance and long bearing life.

Machine stored and operated in a

clean, dry environment.

2-pump shots of grease after 500 hours.

2" shaft or larger.

1-pump shot of grease after 500 hours.

3/4"- 2" shaft.

Machine stored and operated in a

dirty, dusty environment.

2-pump shot of grease after 250 hours.

2"- shaft or larger.

1-pump shot of grease after 250 hours.

3/4”

-

2” shaft.

Machine stored and operated in a

wet environment.

1-pump shot of grease after 50 hours.

3/4”

-

2” shaft or larger.

Woodchips alone do not constitute dust and can be considered a clean environment. Unless you

use the woodchipper in a wet and dirty environment, grease the bearings at 500-hour intervals.

PTO Shaft

Grease the two grease nipples on the universal joints every 10 hours using high-quality multi-

purpose grease.

7.3

Hydraulic oil reservoir

Fill the oil reservoir with 8 gallons of 46HM Hydraulic oil.

Using the specified oil will give you the most extended life and the best performance for this

machine.

The hydraulic system is a low-pressure, low-flow fluid power transfer system. A higher viscosity oil

is not required.

Using an unapproved oil will result in low pump and infeed motor efficiency, causing the feed

rollers to stop functioning correctly.

7.4

Preventive Maintenance

Regular hydraulic system inspection is in everyone's interest; downtime due to overdue

maintenance is always more expensive.

◼

Scheduled inspections at set times after a certain number of hours of operation, checking

crucial components preventively, can avoid costly repairs and downtime.

◼

To avoid skipping certain parts, a good practice is to follow the direction of the oil. Starting at

the reservoir.