20

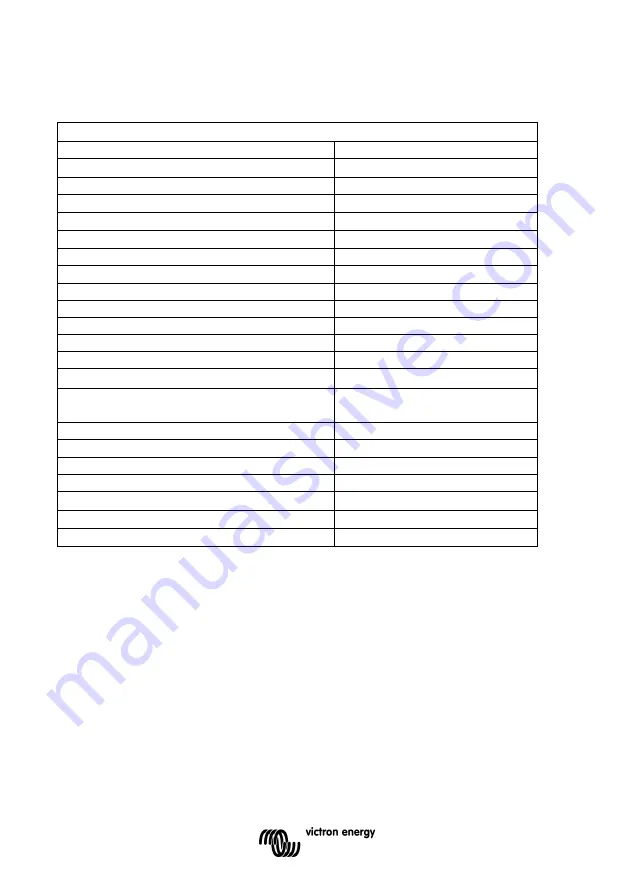

10 TECHNICAL SPECIFICATIONS BATTERIES

Victron Lithium-Ion Battery 24V / 180Ah

Technology

Lithium-Iron Phosphate (LiFePo4)

Nominal voltage

26,4 V

Nominal capacity

180 Ah

Nominal power

4,75 KWh

Power / Weight ratio

86 Wh/Kg

Charge/Discharge

Charge cut-off voltage at 0,05C

28,8 V

Discharge cut-off voltage

20 V

Recommended charge/discharge current (0,3C)

54 A

Maximum charge current (1C)

180 A

Maximum discharge current (1,5C)

270 A

Pulse discharge current (10s)

1000 A

Cycle Life @80% DOD (0,3C)

2000

Enclosure

Common Characteristics

Material: Aluminum and Metal;

Protection: IP20;

Battery connections

M10 bolts

Weight

55 Kg

Dimensions (l x w x h in cm)

62,5 x 35,0 x 18,8

Temperature

Operating temperature during charge

0~45 °C

Operating temperature during discharge

-25~45 °C

Storage temperature

-25~55 °C

Summary of Contents for Lynx Ion

Page 1: ...Manual EN Lynx Ion 24V 180Ah Lithium Ion Batteries ...

Page 2: ......

Page 17: ...15 3 Start VEConfigure3 and configure the Li ion BMS Support assistant as follows ...

Page 23: ...21 APPENDIX A OVERVIEW LYNX ION Bottom view B A D E F C ...

Page 24: ...22 Front view I G H J ...

Page 28: ......