1800W MITER SAW ENG

6)

Keep handles dry, clean, and free from oil and grease. Greasy, oily handles are slippery causing

loss of control.

7)

Operate the power tool only when the work area to the workpiece is clear of any adjusting tools,

wood chips, etc. Small pieces of wood or other objects that come in contact with the rotating saw blade

can strike the operator with high speed.

8)

Keep the floor free of wood chips and material remainders. You could slip or trip.

9)

Always firmly clamp the piece to be worked. Do not saw workpieces that are too small to clamp.

Otherwise, the clearance of your hand to the rotating saw blade is too small.

10)

Use the machine only for cutting the materials listed under Intended use. Otherwise, the machine

can be subject to overload.

11)

Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure

than by hand.

12)

Connect the power tool to a dust collection device and ensure that it is operated properly.

13)

Avoid cutting nails. Inspect the workpiece and remove all nails and other foreign objects before

beginning sawing.

14)

If the saw blade should become jammed, switch the machine off and hold the workpiece until the

saw blade comes to a complete stop. To prevent kickback, the workpiece may not be moved until after

the machine has come to a complete stop. Correct the cause for the jamming of the saw blade before

restarting the machine.

15)

Do not use dull, cracked, bent or damaged saw blades. Unsharpened or improperly set saw blades

produce narrow kerf causing excessive friction, blade binding and kickback.

16)

Always use saw blades with correct size and shape of arbor holes. Saw blades that do not match

the mounting hardware of the saw will run eccentrically, causing loss of control.

17)

Do not use high speed steel (HSS) saw blades. Such saw blades can easily break.

18)

During slide cutting, always ensure that the saw blade is pushed away from the operator

19)

Never leave the machine before it has come to a complete stop. Cutting tools that are still running

can cause injuries.

20)

Do not touch the saw blade after working before it has cooled. The saw blade becomes very hot

while working.

21)

Store the machine in a safe manner when not being used. The storage location must be dry and

lockable. This prevents the machine from storage damage, and from being operated by untrained

persons.

22)

Do not direct the laser beam at persons or animals and do not stare into the laser beam yourself,

not even from a distance. This power tool produces laser class 2 laser radiation according to EN

60825-1. This can lead to persons being blinded.

23)

Do not replace the installed laser with another laser type. A laser that does not fit to this power tool

could pose dangers for other persons.

24)

Wear gloves when handling saw blades.

25)

Periodically check that all nuts, bolts and other fixings are properly tightened.

26)

When an extension cord is required you must ensure it has the correct ampere rating for your

power tool and that it is in a safe electrical condition. Fully unwind extension cords to avoid potential

overheating.

11

Summary of Contents for WD030210254

Page 1: ...Miter saw WD030210254 1800W...

Page 4: ...WD030210254 4 1 1 2 2 4 4 5 5 7 7 8 8 10 10 11 11 3 3 6 6 9 9 12 12 3 2 1 6 5 4 9 8 7 12 11 10...

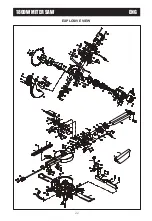

Page 22: ...1800W MITER SAW ENG EXPLOSIVE VIEW 22...

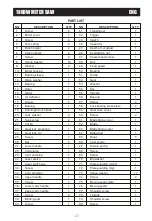

Page 26: ...26 WD030210254...

Page 27: ...27 WD030210254...

Page 28: ...MADE IN CHINA Copyright WIDO Machinery Co Ltd All rights reserved www widopt com...