9

VIEGA 1-800-976-9819

PI-16015-03/09

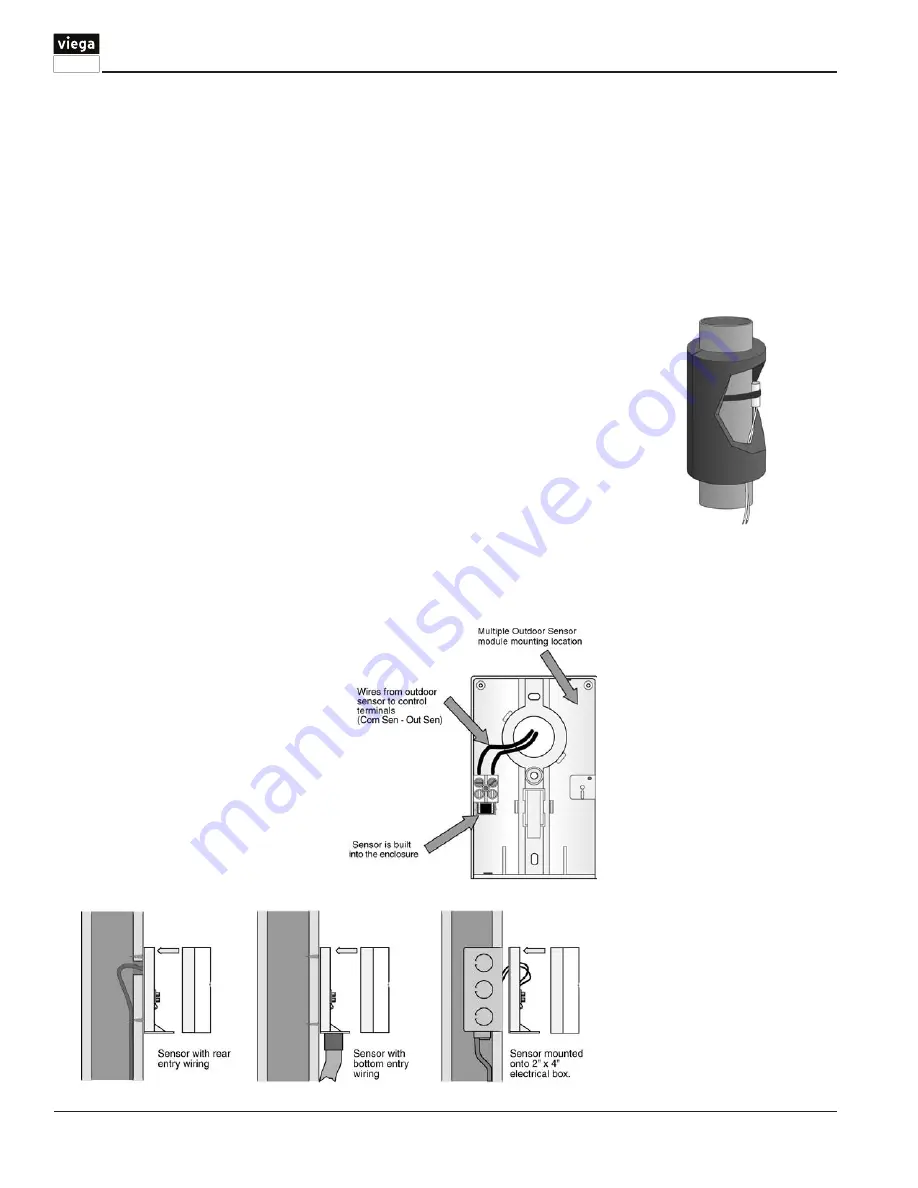

Installing the outdoor sensor

The Outdoor Sensor includes a

10k

Ω

thermistor that provides an

accurate measurement of the

outdoor temperature. The sensor

is protected by a white U.V. resistant

plastic enclosure.

Remove the screw and pull the front

cover off the sensor enclosure.

The Outdoor Sensor can either be

mounted directly onto a wall or a

2" x 4" electrical box. When the

sensor is wall mounted, the wiring

should enter through the back or

bottom of the enclosure. Do not

mount the sensor with the conduit

knockout facing upward as rain

could enter the enclosure and

damage the sensor.

In order to prevent heat transmitted

through the wall from affecting the

sensor reading, it may be necessary

to install an insulating barrier behind

the enclosure.

The Outdoor Sensor should be

mounted on a wall that best

represents the heat load on the

building (a northern wall for most

buildings, and a southern facing wall

for buildings with large south facing

glass areas). The sensor should not

be exposed to heat sources such as

ventilation or window openings.

The Outdoor Sensor should be

installed at an elevation above the

ground that will prevent accidental

damage or tampering, and where it

will not be covered by drifting snow

during the winter.

Connect 18 AWG or similar wire to

the two terminals provided in the

enclosure and run the wires from

the sensor to the control. Do not

run the wires parallel to telephone

or power cables. If the sensor

wires are located in an area with

strong sources of electromagnetic

interference (EMI), shielded cable or

twisted pair should be used or the

wires can be run in a grounded metal

conduit. If using shielded cable, the

shield wire should be connected

to the COM sensor terminal on the

control and not to earth ground.

Replace the front cover of the

sensor enclosure.

When more than one Basic Heating

Control is used on a project, the

Outdoor Sensors can be combined

into one enclosure by adding the

Multiple Outdoor Sensor module

(stock code 16020). This mounts

in the Outdoor Sensor enclosure

and allows up to four controls to

have outdoor sensors within

one enclosure.

Installing the supply sensor

Note: This sensor is designed to

mount on a pipe or in a temperature

immersion well.

The Supply Sensor can be strapped

directly to the pipe using a plastic

cable tie. Insulation should be

placed around the sensor to reduce

the effect of air currents on the

sensor measurement.

The Supply Sensor should be placed

downstream of a pump or after

an elbow or similar fitting. This is

especially important if large diameter

pipes are used, as the thermal

stratification within the pipe can

result in erroneous sensor readings.

Proper sensor location requires that

the fluid is thoroughly mixed within

the pipe before it reaches the sensor.

When using the Supply Sensor with

a Viega Mixing or Injection Station,

insert the sensor into the immersion

well on the elbow below the

circulator pump.

Connect 18 AWG or similar wire

to the two wires of the sensor

and then to the control. Do not

run the wires parallel to telephone

or power cables. If the sensor

wires are located in an area with

strong sources of electromagnetic

interference (EMI), shielded cable or

twisted pair should be used or the

wires can be run in a grounded metal

conduit. If using shielded cable, the

shield wire should be connected

to the COM sensor terminal on the

control and not to earth ground.

InstALLAtIon - CHAPtER 5