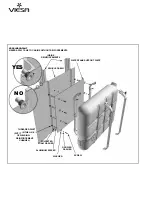

THIS VALVE MUST BE

INSTALLED BELOW THE

THE UPPER EDGE OF THE

WATER TANK.

IN TILT CABINS

OR WATER TANKS INSTALLED

ON THE CHASSIS

THE VALVE MUST BE INSTALLED

AT MORE THAN 1 M BELOW

THE EVAPORATOR'S LOWER EDGE.

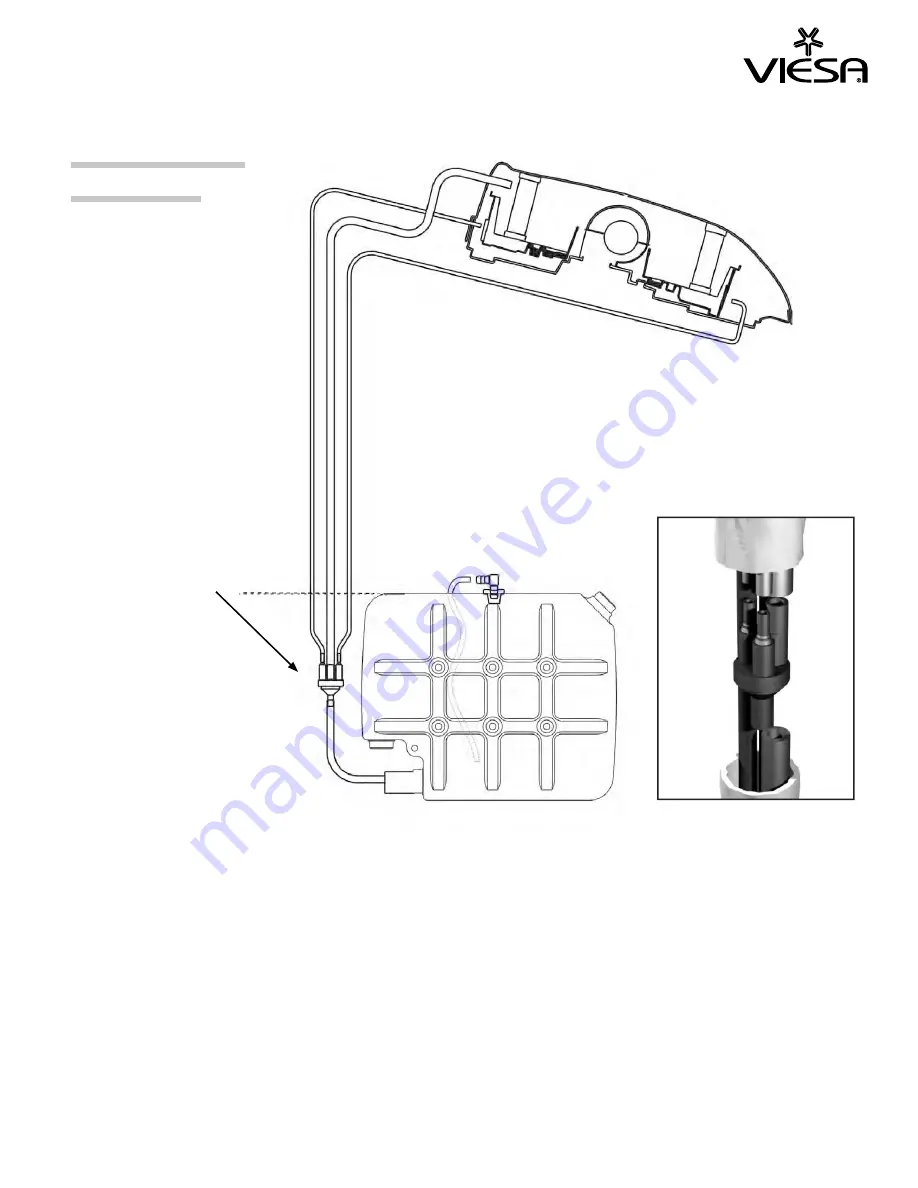

Note:

cut the tubes accordingly. The grey cord wrap must cover all

the hoses and wires until it reaches the pump cover.

Important:

to install the elbow (for ventilation) in the

tank, make a 22 mm. diameter hole

in the center of the top the

tank

(remove shavings). Use the elbow provided.

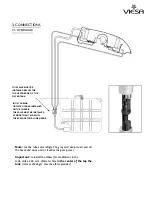

3- CONNECTIONS

3.1- HYDRAULIC