47

Note

According to EN 806, a visual inspection and (if neces-

sary) cleaning must be carried out no later than two

years after commissioning, and as required thereafter.

1.

8x

3.

2.

A

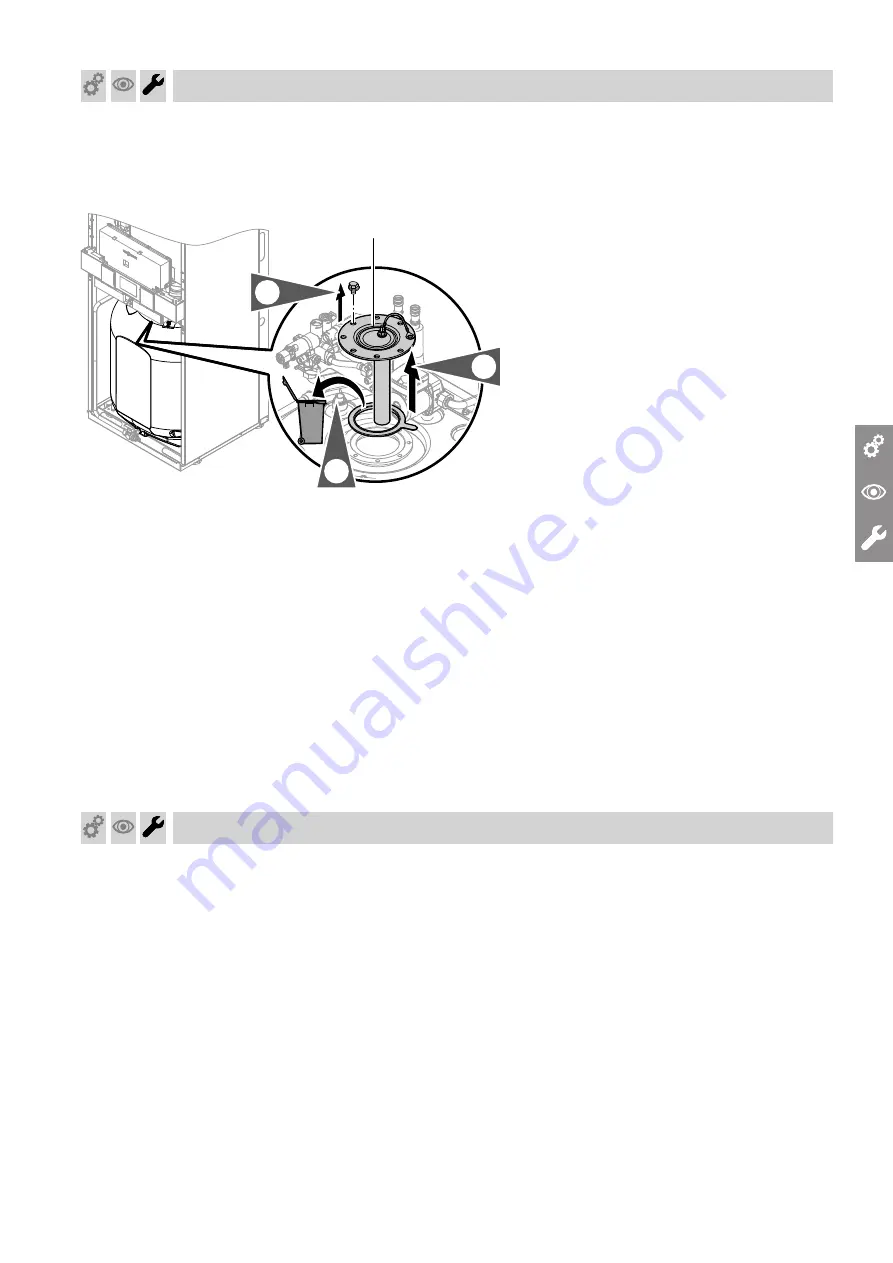

Fig. 37

1.

Drain the loading cylinder.

2.

Remove flange cover

A

.

3.

Disconnect the loading cylinder from the pipework

to prevent contamination from entering the pipe-

work.

4.

Remove loose deposits with a high pressure

cleaner.

!

Please note

When cleaning the inside,

only use plastic cleaning utensils.

5.

Use a chemical cleaning agent to remove hard

deposits that cannot be removed with a high pres-

sure cleaner.

!

Please note

Never use hydrochloric acid

based cleaning agents.

6.

Thoroughly flush the loading cylinder after clean-

ing.

Checking and replacing the magnesium anode (if required)

Check the magnesium anode. If it is discovered that

the anode has degraded to 10 to 15 mm Ø, we recom-

mend replacing the magnesium anode.

Commissioning, inspection, maintenance

Cleaning the loading cylinder

5789 302 GB

Summary of Contents for B2TB

Page 6: ...6 15 Keyword index 152 Index Index cont 5789 302 GB ...

Page 117: ...117 Parts lists Hydraulics 5789 302 GB Components ...

Page 154: ...154 5789 302 GB ...

Page 155: ...155 5789 302 GB ...