15

Note

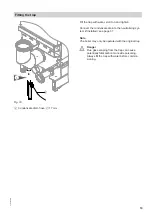

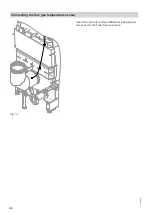

We recommend that you use the Viessmann gas sup-

ply pipe (accessories).

1.

Connect the gas supply according to TRGI 2008

[or local regulations].

a

Connect the gas supply according to ÖVGW-

TR Gas 2009 and the regionally applicable

Building Regulations.

c

Connect the gas supply according to SVGW.

■

Gas supply pressure: 20/25 mbar (2/2.5 kPa)

■

Max. permiss. gas supply pressure: 30 mbar

(3 kPa)

■

Gas connection:

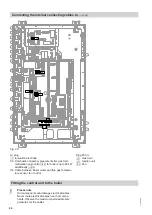

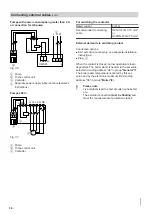

Boiler size

Connection

80 kW

G 1

120 to 318 kW

G 1

½

!

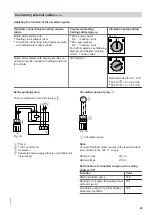

Please note

Mechanically loaded gas supply pipes lead

to leaks and appliance damage.

■

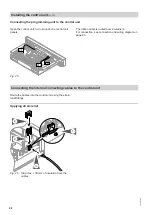

When undoing or tightening gas connec-

tions, counterhold with a second open-

ended spanner.

■

Ensure all gas connections are kept free of

load and torque stress.

2.

Carry out a tightness test.

Note

Only use suitable and approved leak detection

agents (EN 14291) and devices for the tightness

test. Leak detection agents with unsuitable constit-

uents (e.g. nitrites, sulphides) can cause material

damage.

Remove residues of the leak detection agent after

testing.

!

Please note

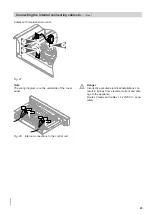

Excessive test pressure will damage the

burner and gas train.

Max. test pressure 150 mbar

. If a higher

pressure is required for tightness tests, dis-

connect the burner and gas train from the

main supply pipe. Undo the fitting.

Note

Just closing the gas shut-off valve is not sufficient.

There is then a risk of pressure entering the valve.

Damage due to excessive test pressure is

excluded from our warranty.

3.

Purge the gas line.

Note

The [German] Combustion Order stipulates that ther-

mally activated shut-off equipment must be installed in

the gas supply line.

If the gas line is contaminated (e.g. old pipes with cor-

rosion products), we recommend installing a gas filter

in the supply line.

Danger

Escaping gas can lead to explosions which may

result in serious injury.

Never purge the gas line through the boiler com-

bustion chamber.

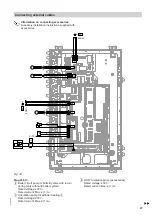

Burner connections on the gas side

5792 916 GB

Summary of Contents for CI1

Page 43: ...43 5792 916 GB ...