10

M

Type T0S-ze only:

■

Temperature sensor, external heat generator

or

■

High limit safety cut-out for stopping the solar cir-

cuit pump

N

DHW circulation R ¾

O

DHW R ¾

P

Condensate

7

20 mm

Q

Sensor well for draw-off profile recognition

R

Power cable (3 m long)

Transport and siting

!

Please note

Impacts, compression and tensile loads can

cause damage to the outside panels of the

appliance.

Never

put weight on the top or front of the appli-

ance or cylinder jacket.

The DHW heat pump can be transported vertically or

horizontally.

Note for horizontal transport

Position the DHW heat pump. Allow the DHW heat

pump to stand for at least 24 hours before commis-

sioning.

Lifting straps (accessories) are available to facilitate

transport.

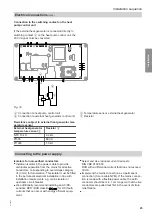

Installation room requirements

■

The installation room must be dry and free from the

risk of frost.

■

The intake air must be kept free from dust, grease

and contamination through halogenated hydrocar-

bons (e.g. as contained in sprays, paints, solvents

and cleaning agents).

■

To prevent the transmission of structure-borne noise,

never site the appliance above ceilings with wooden

joists (e.g. in the attic).

■

A separately fused standard power socket must be

available.

■

A condensate drain pipe must be available.

■

Always maintain the minimum clearances for service

and maintenance work.

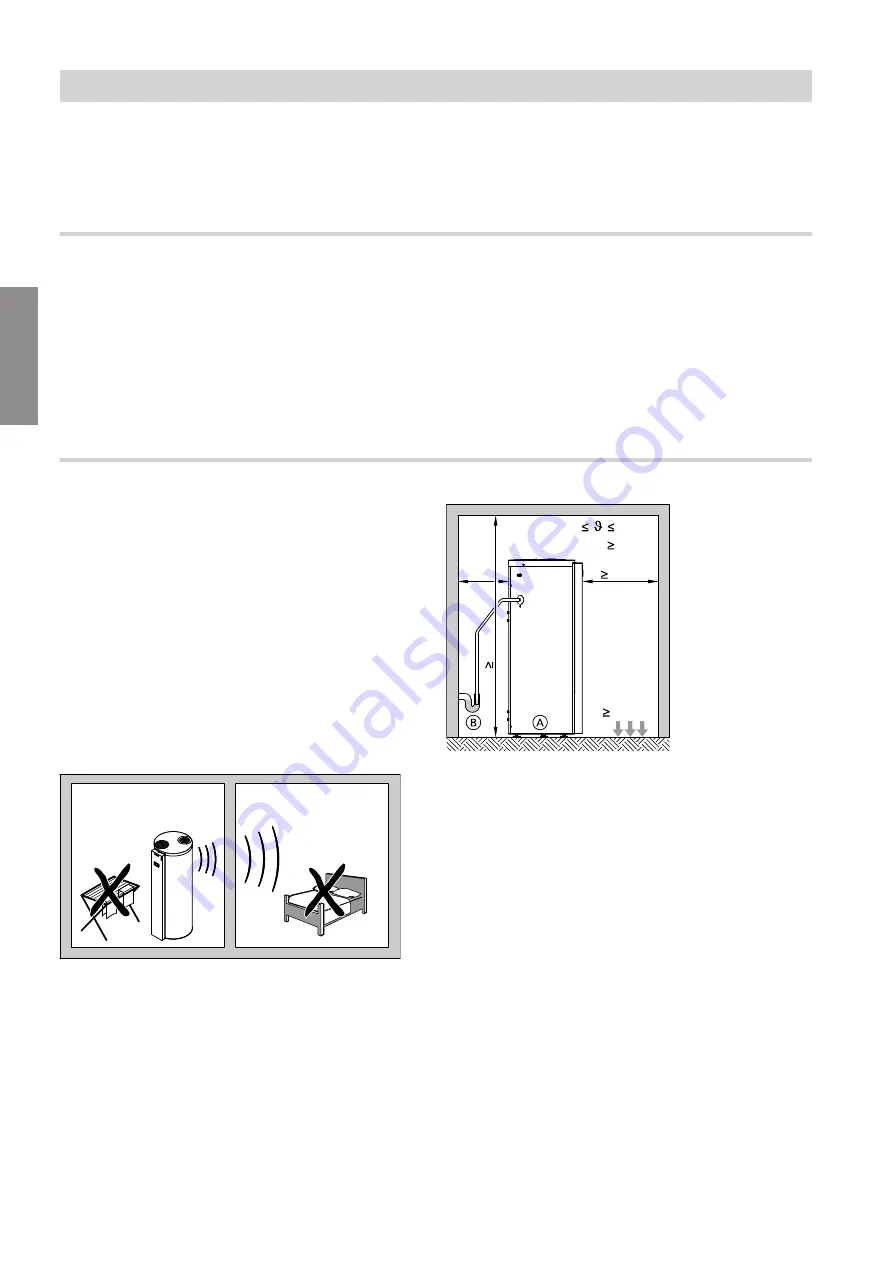

Fig. 3

Minimum clearances

Recirculation air mode

Note

The specified appliance output cannot be guaranteed if

the room volume is < 20 m

3

.

V 20 m³

2 °C

40 °C

500 kg

2000

650

100

Fig. 4

A

DHW heat pump

B

Condensate drain pipe

Recirculation air mode with air discharge to the

outside

Note

■

The specified appliance output cannot be guaran-

teed if the room volume is < 20 m

3

.

■

This operating mode is only permissible in unheated

rooms.

Preparing for installation

Preparing for installation

(cont.)

6136003

Installation