16

Information on ductwork

!

Please note

The simultaneous operation of open flue com-

bustion equipment (e.g. an open fireplace) and

the DHW heat pump in a space with combustion

air interconnection results in dangerous negative

pressure inside the room. Negative pressure

can result in flue gases re-entering the room.

■

Never

operate the DHW heat pump simultane-

ously with

open

flue combustion equipment

(e.g. an open fireplace).

■

Operate combustion equipment exclusively in

room sealed

mode with a separate supply of

combustion air. We recommend combustion

equipment with general building regulations

approval as

room sealed

combustion equip-

ment, issued by the Deutsches Institut für

Bautechnik DIBt [or local equivalent].

■

Doors to boiler rooms where the combustion

air supply is not interconnected with the living

space must be airtight and must be kept shut.

Note

In recirculation air mode with air discharge to the out-

side, ensure an adequate supply of fresh air to the

installation room (on site), e.g. via separate vents (min.

DN 160).

■

Thermally insulate the ductwork with vapour diffu-

sion-proof material.

■

Always route the ducts for air intake and air dis-

charge with a 2 to 3° fall, so that rain and conden-

sate can drain away to the outdoors.

■

Ensure air intake temperatures from -5 to 35 °C.

■

Maximum permissible total pressure drop

Δ

p

total

(ductwork and appliance): 100 Pa

■

Fit silencers to prevent flow noise.

■

Ducts, wall outlets and connections to the DHW heat

pump can be installed using anti-vibration insulation

to reduce noise (see diagram).

Connections and installation options which are not per-

missible:

■

Connection of kitchen extractor hoods to the duct-

work

■

Installation of a DHW heat pump with recirculation air

mode in a heated room

■

Connection of the air intake duct to a mechanical

ventilation system

■

Connection of the air intake duct to an air/geothermal

heat exchanger

■

Connection of the air intake duct to a tumble dryer

■

Reversed connections (air intake to the outside and

air discharge to the inside)

■

Installation of the DHW heat pump in an attic

■

Installation of the DHW heat pump in dusty rooms

■

Operation of the DHW heat pump in conjunction with

an open flue boiler

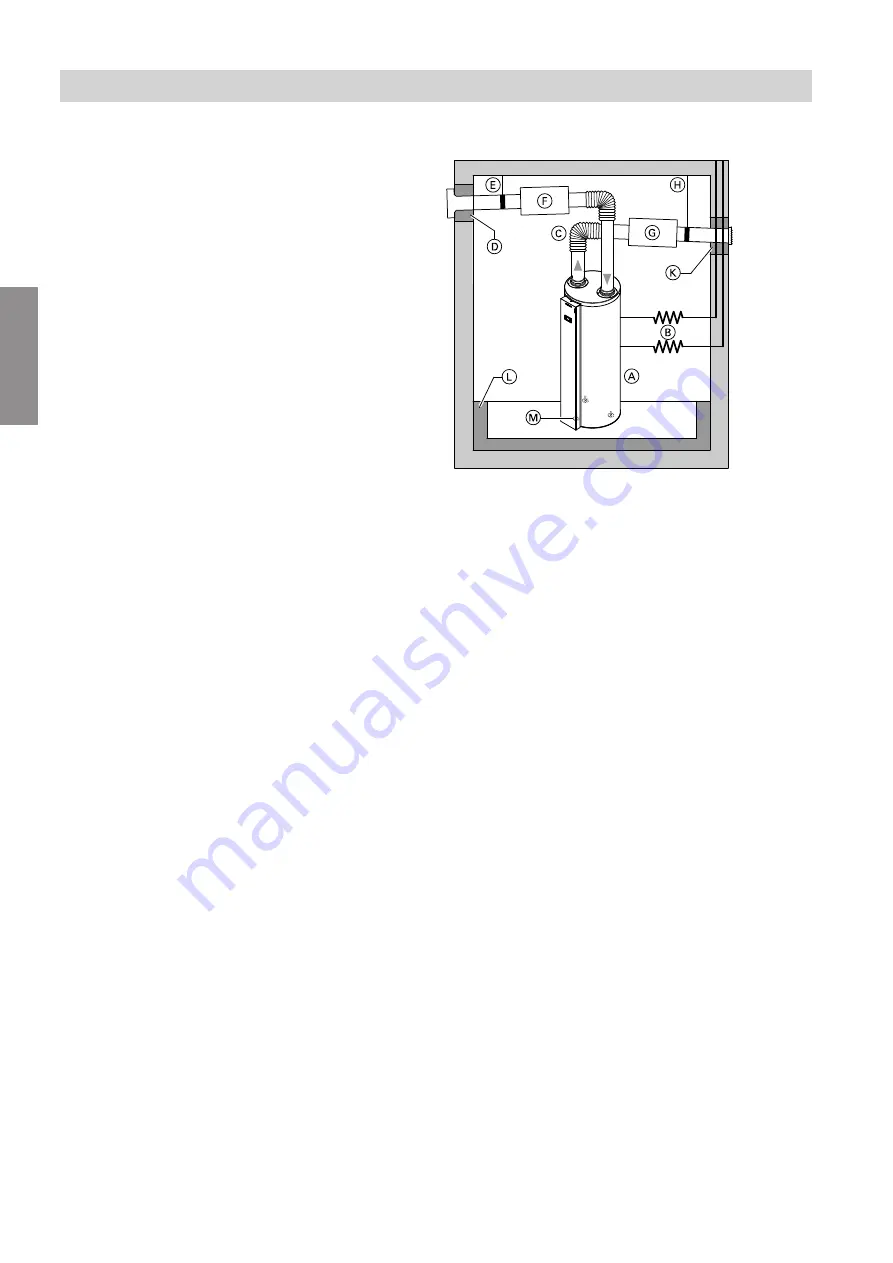

Anti-vibration insulation

Fig. 11

A

DHW heat pump

B

Flexible hydraulic connections

C

EPP insulated plastic pipes or insulated flexible

pipes (min. DN 160) for air intake/air discharge

ductwork

D

Anti-vibration insulation for air intake wall duct

E

Anti-vibration bracket for air intake duct

F

Air intake silencer

G

Air discharge silencer

H

Anti-vibration bracket for air discharge duct

K

Anti-vibration insulation for air discharge wall duct

L

Anti-vibration insulation for floor

M

Adjustable feet

Measures for minimising the pressure drop

■

Use as few bends as possible.

■

As far as possible, avoid elements that increase the

pressure drop.

■

Route the air intake duct above the air discharge

duct if possible.

Positioning of air intake and air discharge aper-

tures

!

Please note

An "air short circuit" will result in the cooled dis-

charged air being drawn back in to the unit. This

can result in reduced heat pump efficiency and

defrosting problems.

Position the air intake and air discharge aper-

tures so that any "air short circuit" is prevented.

Installation sequence

Conversion to outdoor air mode

(cont.)

6136003

Installation