31

5285 429 - 03

Vitorond 200, VD2 Series 320 to 1080 Installation

Enclosure

Boiler Control Installation

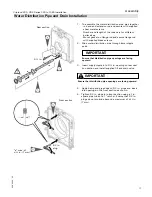

3. Install control harness bracket using supplied 8-32

self-tapping

screws.

4. Install burner harness bracket and tighten the two

supplied

screws.

5. Install top mounting hole cover with two supplied self

tapping

screws.

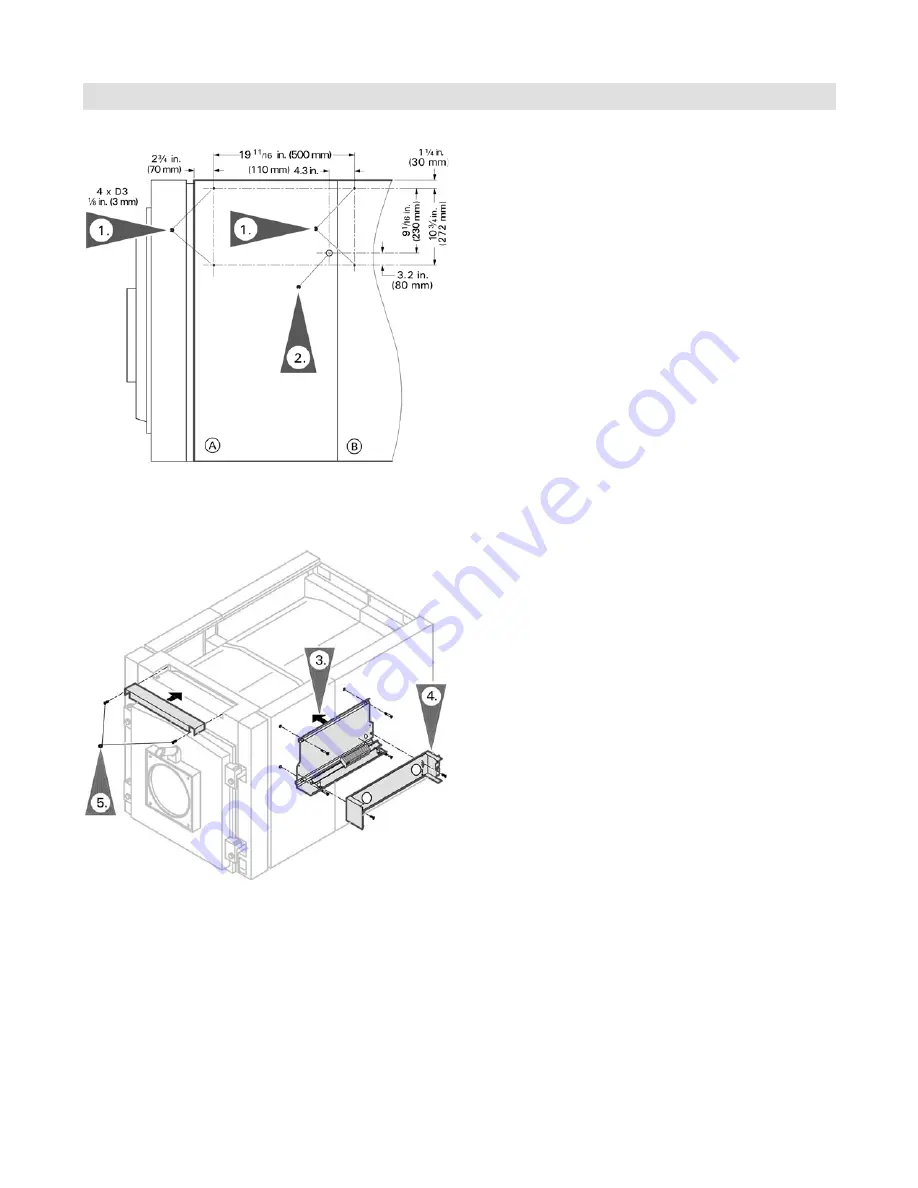

1. Drill four Ø

d

in. (3 mm) holes on the side panels

A

and

B

as shown. For left-side mount use a mirror

image of the drawing.

2. Punch a Ø

7

/

8

in. (22 mm) opening.

Note:

On VD2-500, -560, 630 and -1080 boilers,

the bracket mounting overlaps side panel

B

.