35

5285 429 - 03

Vitorond 200, VD2 Series 320 to 1080 Installation

System Preparation

Start-up

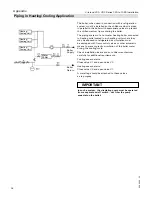

Combustion air supply

Provisions for combustion and ventilation air must be made

in accordance with applicable local codes.

In the absence of local codes, use CAN/CSA-B149.1 or .2

Installation Codes for Gas Burning Appliances for Canada.

For U.S. installations use section 5.3, Air for Combustion

and Ventilation, of the National Fuel Gas Code ANSI

Z223.1.

For oil burning installations use CSA B-139 for oil

installations in Canada and NFPA 31 Standard for the

Installation of Oil Burning Equipment in the US.

Always use latest editions of codes.

Whenever possible, install boiler near an outside wall

so that it is easy to duct fresh air directly to the boiler

area. Refer to national codes for duct sizing and allowable

lengths. Round ducts can be used.

The boiler location must never be under negative pressure.

Exhaust fans, attic fans, or dryer fans may cause air to be

exhausted at a rate higher than air can enter the structure

for safe combustion.

WARNING

Failure to provide an adequate supply of fresh

combustion air can cause poisonous flue gases

to enter living space which can cause severe personal

injury or loss of life.

WARNING

Never cover the boiler or store debris or other

materials near the boiler, or in any way block the flow

of adequate fresh air to the boiler.

Never cover the combustion air opening or put anything

inside the draft hood.

Advise system operator/ultimate owner accordingly.

WARNING

The boiler must not be located in areas or rooms

where chemicals are stored, or aggressive vapors

from (i.e. bleach, hair spray, methyl chloride, carbon

tetrachloride or perchloroethylene) or high dust levels

or humidity levels are present.

Heat exchanger corrosion might occur and reduce

the lifetime of the boiler significantly. If above criteria

are not properly observed and boiler damage results,

any warranty on the complete boiler and related

components will be null and void.

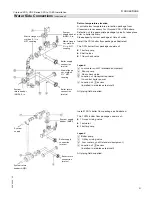

Gas piping pressure test

A sediment trap/dirt pocket must be provided upstream

of all gas controls. Provisions for connecting vent lines

or vent limiters are on gas regulator.

The boiler and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 14” w.c. (3.5 kPa).

The boiler must be isolated from the gas supply piping

system by closing its individual manual shut-off valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 14” w.c.

(3.5 kPa).

Unions and the gas manifold have not been factory-

tested. A leak test must be completed during initial trial

operation of burner by a licensed gas fitter.

1. Connect and size gas supply piping in accordance

with local and national codes.

2. Perform leak test. Never check for gas leaks with

an open flame. Use approved liquid spray solution

for bubble test. Ensure that no liquid is sprayed on

any electrical components, wires or connectors.

Do not allow leak detection fluid to contact gas valve

regulator or regulator vent opening.

3. Remove air from gas line with an approved gas purge

burner or vent to outdoors.

IMPORTANT

½ psig = 14 “w.c.