System Design Considerations

20

VITOROND 200, VD2A

System Design Considerations

Burner Calibration

With 2-stage and fully modulating

burners, ensure that the chimney is

compatible with the lower flue gas

temperatures associated with partial load

conditions set on the burner.

Never operate boiler without an installed

venting system which safely vents all

products of combustion to the outdoors.

The vent system must comply with all

applicable local and/or national codes.

Vitorond 200, VD2A boilers are Category I

and III boilers as defined in ANSI Z21.13

when used with natural gas and LP. Venting

systems shall be sized and constructed in

accordance with approved engineering

methods (ASHRAE, HVAC Systems and

Equipment Handbook, Chapter 31

“Chimney, Gas Vent, and Fireplace

Systems”) including the chimney and boiler

manufacturer’s instructions.

In Canada

For gas-fired boilers install venting system in

accordance with all applicable local codes.

In the absence of local codes, follow

national codes CAN/CSA B149.1 or .2 or

latest edition.

For oil-fired boilers follow CSA B-139 or

latest edition.

In U.S.A.

For gas-fired boilers connecting to gas vents

or chimneys, vent installations shall be in

accordance with Venting of Equipment of

the National Fuel Gas Code, ANSI Z223.1 or

applicable provisions of the local building

codes.

For oil-fired boilers follow NFPA 31. Always

use latest code editions.

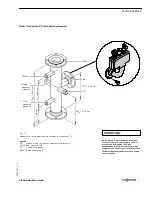

Venting (option #1)

The Vitorond 200, VD2A boiler is approved

as a

Category I

appliance and must be

vented accordingly.

Chimney

For proper operation of the Vitorond 200,

VD2A boiler, all products of combustion

must be safely vented to the outdoors, while

ensuring that flue gases do not cool

prematurely.

It is critical that the chimney system be

properly designed to handle the relatively

cool flue gas temperatures produced by the

Vitorond 200, VD2A boiler.

If the chimney system lacks sufficient

insulation and/or the chimney diameter is

too large, corrosive and damaging

condensation will result due to flue gases

cooling too quickly. If a calculated chimney

diameter lies between two values, the larger

diameter should be selected.

The chimney connection length between the

boiler vent pipe collar and the chimney must

be installed with insulation.

Vent pipe collar diameter does not

automatically indicate vent/chimney size.

We recommend consulting a reputable

chimney installer for advice in

project-specific circumstances.

When installing the Vitorond 200, VD2A

boiler, it is necessary to install a barometric

draft regulator in the chimney/vent for

proper operation of the boiler.

Install the barometric draft regulator within

5 to 7 ft. / 1½ to 2 m from the breeching

outlet located at the rear of the boiler.

Barometric draft regulator type

For natural gas or propane applications, use

a double-acting type. For #2 fuel oil

applications, use a single-acting type.

Barometric draft regulator diameter

The barometric draft regulator

must be the

same diameter

opening as the chimney for

which the vent is sized.

For example, a 14” chimney would require a

14” barometric draft regulator. Do

not

size

the barometric draft regulator to the

breeching outlet of the boiler, unless the

chimney is also intended to be of that

diameter.

The size of the flue gas outlet on the boiler

does not automatically determine the

horizontal breeching, or the actual chimney

diameter. The chimney size must be

designed for the actual boiler model and its

input.

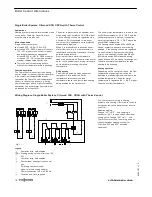

Venting (option #2)

The Vitorond 200 boiler is a

Category III

positive pressure non-condensing boiler.

Each boiler must be vented individually.

The vent system must be properly designed

and suitable materials must be selected. The

chimney must be gas tight.

Use an AL29-4C® special stainless steel

venting system (UL/ULC listed for Category

III) for single-wall vertical venting of the

Vitorond 200 boiler.

For more details on the positive pressure

venting option, see the Viessmann

installation instructions for the positive

pressure venting system.

The following manufacturers may be

contacted for suitable stainless steel

chimneys:

ProTech Systems Inc.

26 Gansevoort Street

Albany, NY

12202

Tel.: (518) 463-7284

Fax: (518) 463-5271

Toll free: 1-800-766-3473

Selkirk Metalbestos

Selkirk Canada Corporation - head office

375 Green Road

Stoney Creek, ON

L8E 4A5

Tel.: (905) 662-6600

Fax: (905) 662-5352

Toll free:1-800-263-9308

Security Chimneys

Division of Security Chimneys Ltd.

2125 Monterey

Laval, PQ

H7L 3T6

Tel.: (450) 973-9999

Fax: (450) 973-2222

Toll free: 1-800-667-3387

5

3

5

4

7

8

7

v

1

.2

When installing or insulating (overhead)

piping or venting, do not stand on top

panel of boiler. Advise other trades

accordingly!

WARNING

The Vitorond 200, VD2A boiler is not

approved for side wall venting.

CAUTION

IMPORTANT

Barometric draft regulator