6.1 Fuel storage in on-site pellet store

Fuel storage in the pellet storage room

Sizing the pellet storage room

The storage room should ideally be rectangular and large enough to

accommodate a year's supply of fuel. The size of the storage room

depends on the heat load of the building. The floor area should not be

less than 2 x 3 m.

The required size of the storage room for the annual amount of fuel in

m

3

(incl. empty space) is calculated by multiplying the building heat

load (in kW) by a factor of 0.9 (m

3

/kW).

Example:

Building heat load (e.g. detached house) 12 kW

12 kW x 0.9 (m

3

/kW) = 10.8 m

3

Available space (storage room minus unusable area due to sloping

floors) = 10.8 m

3

x 2/3 = 7.2 m

3

Amount of pellets = 7.2 m

3

x 650 kg/m

3

= 4680 kg/m

3

≈ 4.7 t

Storage room size = 10.8 m

3

/ 2.3 m (room height)

= 4.7 m

2

floor area

A room size of 2 m x 3 m is adequate to store a year's supply of fuel.

Stored amount of energy = 4680 kg x 5 kWh/kg = 23,400 kWh

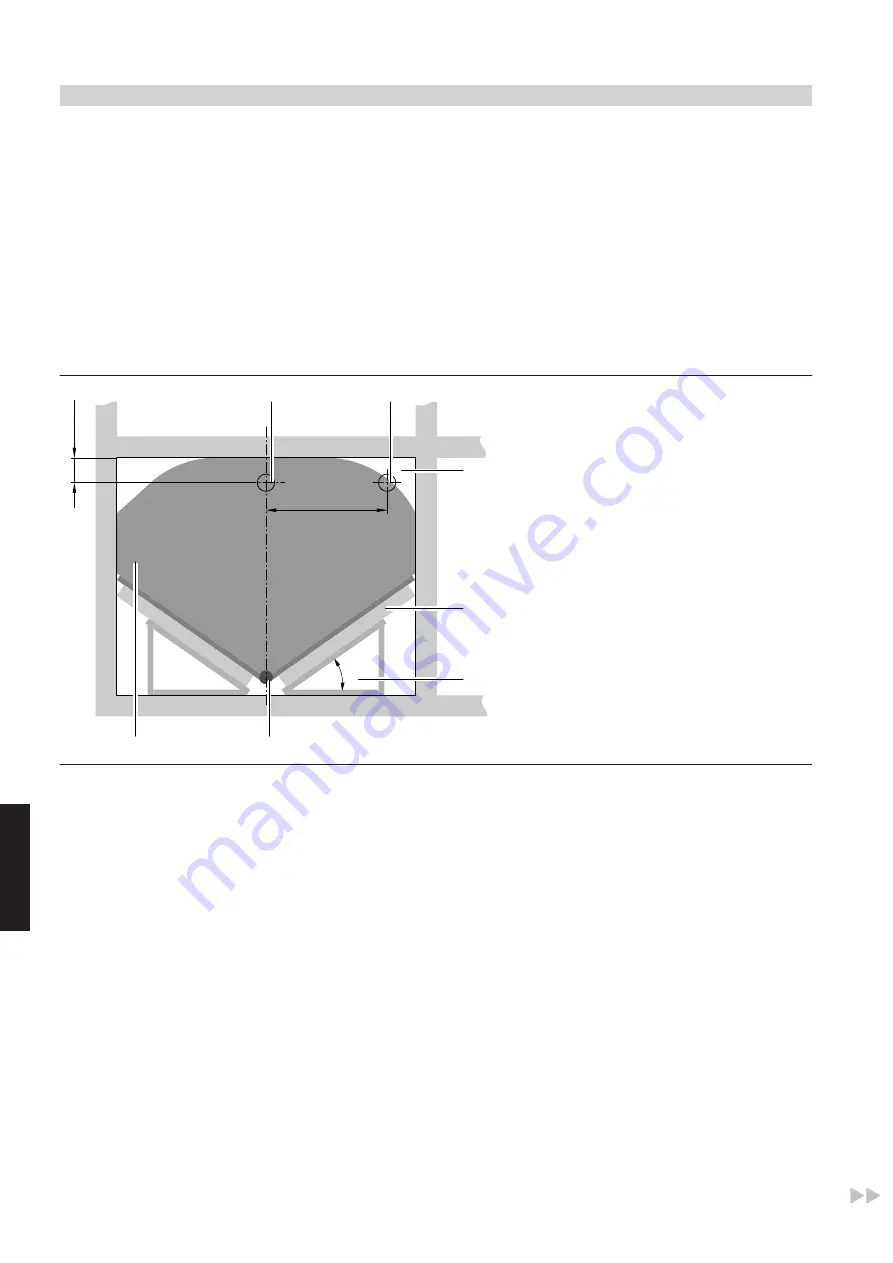

A

B

C

D

E

F

G

200 mm

≥ 500 mm

40°

A

Fill connector

B

Return air connector

C

Clear space

D

Sloping floor

E

Empty space

F

Viessmann discharge system

G

Available volume = ⅔ of the room

General requirements of the pellet storage room and required

system components

■ The pellet storage room must be dry, as pellets will swell up markedly

if exposed to moisture. This leads to substantial difficulties in sup-

plying pellets to the boiler.

■ The pellet storage room must be of solid, dust-tight construction, as

loading pellets into the room creates dust and the pellets will exert

high pressure on the walls.

■ The pellet storage room or the installation room for prefabricated

stores must be vented. Vents should not be positioned directly below

windows or supply air apertures. Observe the requirements for the

ventilation of pellet stores according to VDI Directive 3464. Vents

should be closed during filling, so that the vacuum fan can create a

slight negative pressure in the storage room.

■ According to static requirements, the following wall thicknesses have

proven to be useful:

e.g. bricks 17 cm, rendered on both sides; hollow breeze blocks

12 cm, rendered on both sides; concrete 10 cm, plaster

block12 cm.

From a stored amount of pellets in excess of 6.5 tonnes, surrounding

walls and intermediate ceilings must comply with fire resistance cat-

egory F90.

■ Doors or access hatches into the pellet storage room must open

outwards and must be dust-tight (with an all-round seal). With a

stored amount of pellets in excess of 6.5 t, doors must be self-closing

and have a fire resistance rating of T30.

■ Fit protective boards on the inside of the door opening, so that pellets

do not press against the door.

■ There should be no electrical installations inside the pellet storage

room. Essential electrical installations must be of explosion-proof

type, in accordance with current regulations.

■

a

In Austria, surrounding walls and separating ceilings in the stor-

age room must be designed in accordance with fire resistance cat-

egory F90, and doors or access hatches in accordance with T30.

Observe fire regulations according to TRVB H118 and the respective

statutory requirements.

■ Avoid the installation of water pipes inside the storage room because

of condensation and the risk of burst pipes.

■ Pellet storage rooms should be equipped with a fill connector

H

and

a return air connector

G

with a Storz coupling, type A, Ø 100 mm

(fire hose connector), with extension pipes leading into the pellet

storage room. Pipes should be

metal

, connected to the brickwork

and earthed.

■ Fit a deflector

C

opposite the fill connector to protect the pellets and

the brickwork.

Fuel storage

42

VIESMANN

VITOLIGNO 300-H

6

5672 507 GB