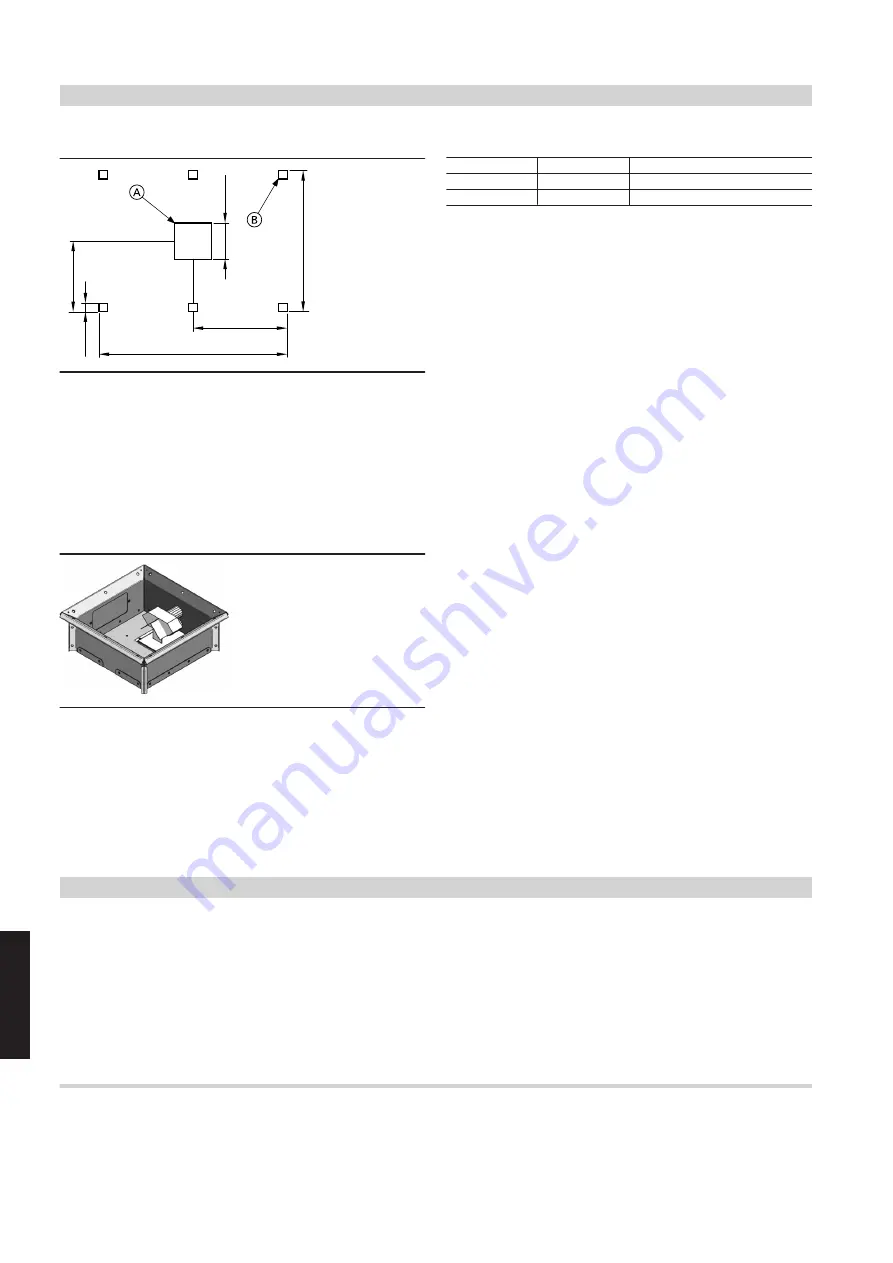

Pellet silo type 17/29 and 21/29

□ 500

□ 150

b

a

1450

2900

A

Max. load on the central support plate: 4000 kg

B

Max. load per support plate: 1500 kg

Pellet silo

Type 17/29

Type 21/29

a in mm

850

1050

b in mm

1700

2100

Filling

The space requirement for the fill and return air connectors is at least

600 mm to enable easy connection of the tanker fill hose. The pellets

should be filled through a window or door. If that is impossible, the

connectors can also be extended to the external wall.

Discharge unit

Subject to the fuel supply system, a discharge unit is required for each

pellet silo (see Vitoset pricelist).

Discharge unit for vacuum system with suction wand

Part no. 7164 633

Fire protection

No special requirements are specified for walls, ceilings, doors or the

utilisation of the room for storage capacities of less than 6.5 t of pellets.

The pellet silo can be installed in the same room as the boiler subject

to the heating system being rated up to 50 kW. In such cases, maintain

a minimum clearance of 1 m. This distance can be reduced if a non-

combustible heat protector is installed between the boiler and the pellet

silo.

Requirements of the fuel storage room are subject to national or

regional regulations and must be complied with.

a

TRVB H118 specifies that the pellet silo is separated from the

boiler by a wall and is installed in a separate room. The ceiling and

walls of the fuel storage room must have a fire rating of F90. Doors

between boiler room and flue store, as well as doors and windows to

the outside must meet standards T30 or G30.

In legal terms, fire safety in Austria is regulated by the various national

building regulations of the individual states; the foundation for these

regulations is TRVB H118. Requirements specified in national building

regulations must be observed.

Design information

7.1 Sizing the system

Selecting the rated heating output

Select the solid fuel boiler according to the required heat load. The

boiler should always be operated in conjunction with a buffer cylinder

(management). The correct system design point therefore does not

depend on the nominal load specification (i.e. the building heat load),

but rather on the required duration of use (length of the heating season,

heat demand).

Note

For locations higher than 1800 metres above sea level, the project

enquiry must include details about the precise geographical location

(altitude and address of the location).

Flow temperatures

To minimise distribution losses we recommend sizing the heat distri-

bution system and the DHW heating in line with a maximum flow tem-

perature of 70 °C.

On solid fuel boilers supplied with a boiler control unit, the maximum

boiler water temperature is limited to 85 °C. The flow temperature may

be increased by adjusting the temperature controller.

Fuel storage

(cont.)

50

VIESMANN

VITOLIGNO 300-H

7

5672 507 GB