6

5608 487

v1.2

Vitocell 100-V Installation Instructions

Tank Connections

Set-up and Connections

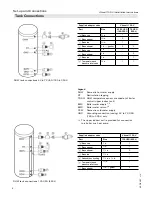

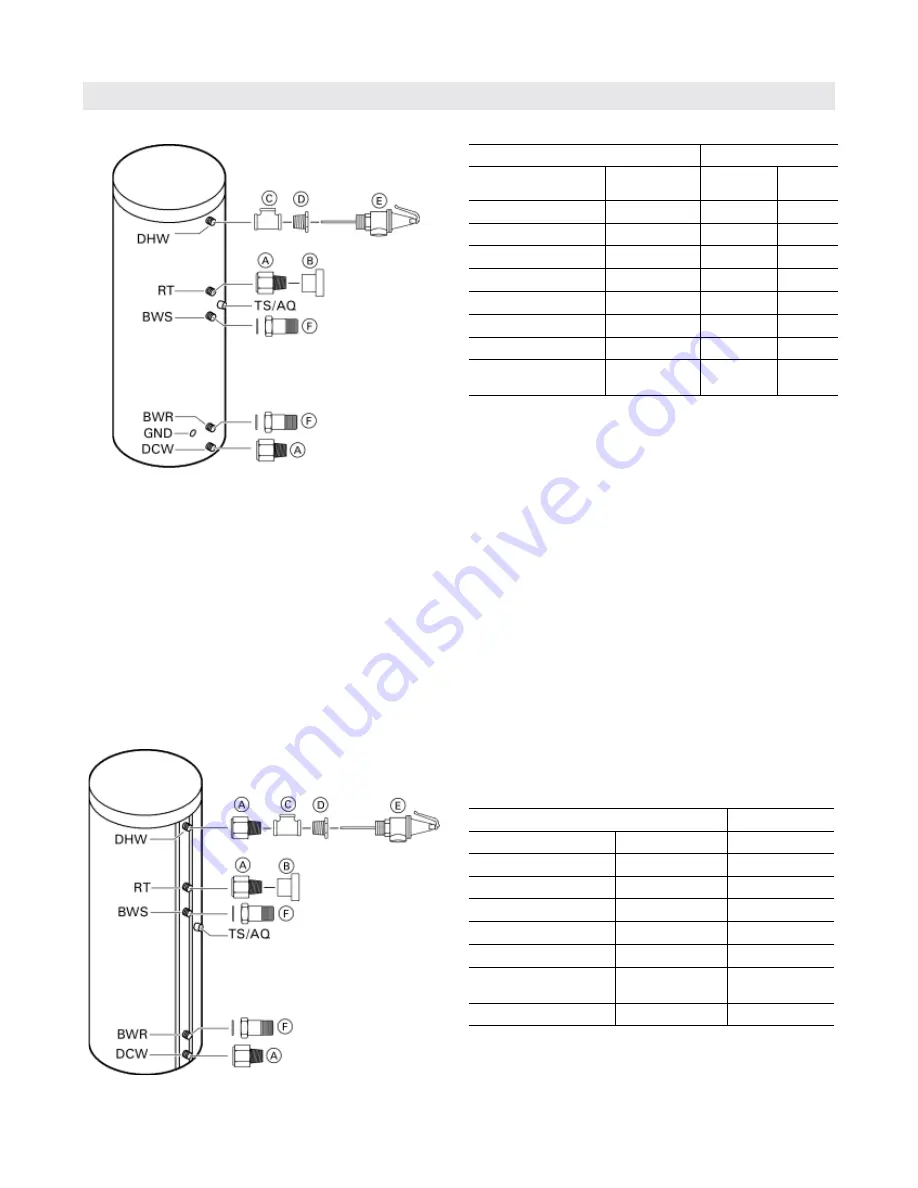

DHW tank connections 120 USG (450 L)

DHW tank connections 42 to 79 USG (160 to 300 L)

Legend

DHW

Domestic hot water supply

RT

Recirculation tapping

TS/AQ DHW temperature sensor or aquastat of boiler

control (upper indirect coil)

BWS

Boiler water supply

*

1

BWR

Boiler water return

*

1

DCW

Domestic cold water supply

GND

Grounding connection (casing) 42 to 79 USG

(160 to 300 L) only

*1

The upper indirect coil is provided for connection

to a boiler or a heat pump.

Supplied adaptor sizes

Vitocell 100-V

Part

Size

42/53 USG

(160/200 L)

79 USG

(300 L)

B

Brass cap

c

in.

1

--

A

Brass adaptor

c

in.

2

--

C

Brass tee

c

in.

1

--

F

Brass adaptor

1 in. + gasket

2

2

B

Brass cap

1

in.

--

1

A

Brass adaptor

1

in.

--

2

C

Brass tee

1

in.

--

1

E

Temperature and

pressure relief valve

c

in.

1

1

Supplied adaptor sizes

Vitocell 100-V

Part

Size

120 USG (450 L)

B

Brass cap

1 in.

1

A

Brass adaptor

1 in.

1

A

Brass adaptor

1

a

in.

2

C

Brass tee

1

a

in.

1

D

Reducer hex bushing

1

a

in. x

c

in.

1

E

Temperature and

pressure relief valve

c

in.

1

F

Brass adaptor

1 in. + gasket

2