16

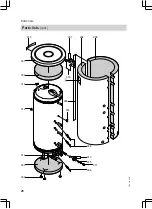

Note

■ Never wrap insulating tape around the

sensor.

■ Secure the sensor on the outside of

the contact spring of the sensor

retainer (not in the groove) so that it is

flush with the front of the spring.

■ Insert the sensor retainer together with

the sensor into the sensor well as far

as it will go.

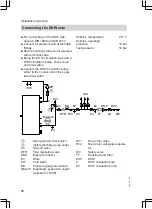

Connecting the equipotential bonding

Connect the equipotential bonding in

accordance with the requirements stipu-

lated by your local power supply utility

and VDE [or local] regulations.

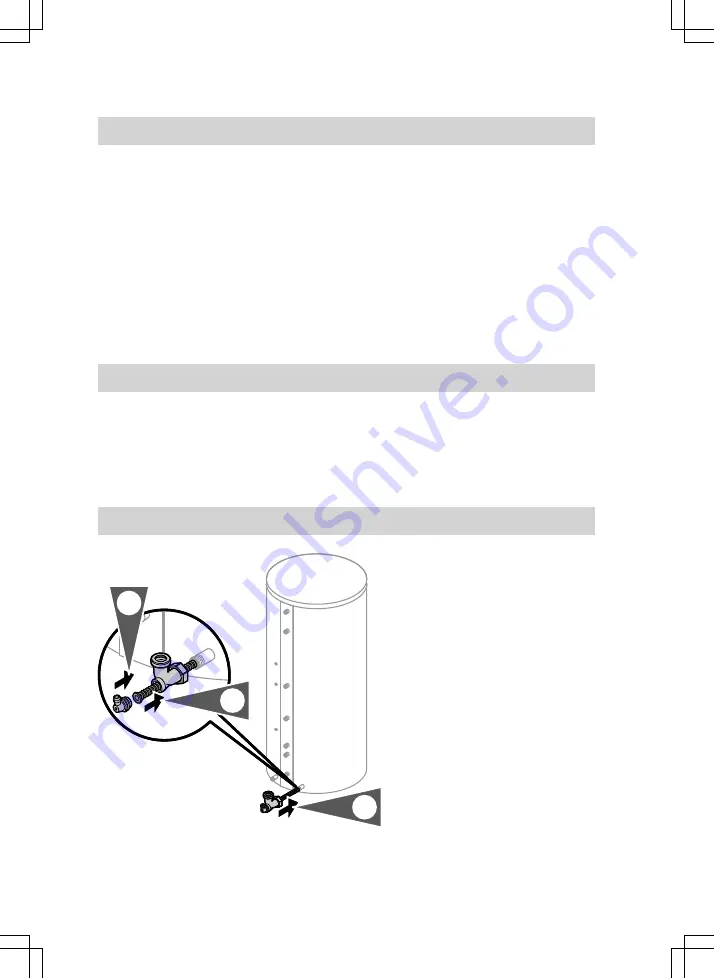

Installing an air vent valve on the solar side

1.

2.

3.

Installation sequence

Fitting the cylinder temperature sensor

(cont.)

5719 714 UAE

Summary of Contents for Vitocell 340-M

Page 31: ...31 5719 714 UAE Service ...