Combustion air supply via horizontal pipes

Rated heat-

ing output

range in

kW

System size

Max. height/length in m

Flue sys-

tem

Ventilation

air routing

Flue

Ventilation

air line

Vitocrossal 200, type CM2

80 to 87

DN 125

DN 150

25

11

80 to 87

DN 150

DN 150

30

30

105 to 115

DN 125

DN 150

10

5

105 to 115

DN 150

DN 150

30

30

130 to 142

DN 150

DN 150

28

11

130 to 142

DN 200

DN 150

30

30

170 to 186

DN 200

DN 150

30

10

170 to 186

DN 200

DN 200

30

30

225 to 246

DN 200

DN 200

26

6

285 to 311

DN 250

DN 250

30

30

Vitocrossal 300, type CT3U

370 to 400

DN 250

DN 250

30

30

460 to 500

DN 250

DN 250

25

15

375 to 630

DN 250

DN 250

8

5

The details apply subject to the following assumptions:

■ Length of the connection piece (flue): 2 m and 3 x 87° bends (includ-

ing support bends)

■ Length of the connection piece (ventilation air line): 2.5 m and 2 x

87° bends

Note

With the Vitocrossal 200 with MatriX radiant burner, a draught of 70

Pa is available for the balanced flue system.

Minimum distance for secondary ventilation between the internal

cross-section of the shaft and the female connection, see page 31.

For

balanced

flue operation, the Vitocrossal 200 requires a flue pipe

between the gas condensing boiler and the shaft (chimney) (type C

33

to TRGI 2008).

System size flue pipe

7

125, 150, 200 and 250 mm.

If the ventilation air supply is routed separately, use individual com-

ponents of the flue pipe size

7

150 or 200 mm.

A boiler flue connection must be ordered for the connection to the

Vitocrossal.

For routing through shafts or ducts with longitudinal ventilation

that meet the requirements for domestic chimneys to DIN V

18160-1, or have a fire rating of 90 min (L90).

For system size diameter 125, 150, 200 and 250 mm

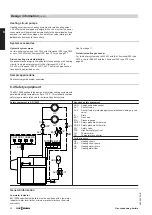

2

A

B

3

4

3

2

3

2

2

4 6

5

C

3

1

3

A

D

A

Ventilation air

B

Flue gas

C

Inspection port

D

Minimum internal shaft dimension (see page 31)

1

Boiler flue connection

(order separately)

Extension

2

Basic shaft unit

comprising

– Support bend

– Support rail

– Shaft cover

– Spacers (3 pce)

Spacers

(3 pce)

3

Pipe

– 2 m long (2 pce = 4 m long)

– 2 m long (1 pce)

– 1 m long (1 pce)

– 0.5 m long (1 pce)

4

Inspection piece

Straight (1 pce)

5

Flue bend

87° (1 pce)

45° (2 pce)

Flue bend

(for use in corbelled chimneys)

30° (2 pce)

15° (2 pce)

6

Inspection bend

87° (1 pce)

Reducer

Design information

(cont.)

36

VIESMANN

Gas condensing boilers

8

5822 449 GB