Attenuating airborne noise

Frequently, modern burners are equipped with silencer hoods or

noise-attenuated ventilation air inlet housings. Additional silencer

hoods may be used where more stringent anti-noise measures are

required. These measures may be implemented later with minimum

effort. Silencer hoods are offered for various levels of sound insulation

and are generally designed and built in accordance with specific sys-

tem conditions (boiler type, fuel supply, building characteristics).

For larger systems it may be necessary to route the ventilation air

through a sound-insulated channel, in order to avoid excess noise

outside the building. Flue gas silencers are generally only required

where higher sound insulation measures are called for. Whether or not

a flue gas silencer is required can be predicted only with some diffi-

culty, because of the complexity of the creation and propagation of

flame noise, the interaction between the burner, boiler and the flue

system as well as the operating mode (flue system operating with pos-

itive or negative pressure).

It is advisable, therefore, to assess the noise emission into the neigh-

bourhood in considering the sound power level measured at the flue

system terminal. It should be considered at the engineering stage

whether flue gas silencers might be necessary. It is thus important that

sufficient space for the flue gas silencer is available behind the boiler.

In accordance with EN 13384, the pressure drop of the flue gas

silencer on the flue gas side will be required for calculating the flue

system.

Structure-borne noise attenuation

Anti-vibration supports for the boiler are an economical and effective

measure. For this purpose, anti-vibration supports are offered. When

sizing such supports, take the entire operating weight of the boiler

system and, when using linear anti-vibration brackets, the condition of

the supporting surface into consideration. Effective structure-borne

noise attenuation is particularly important when installing boilers in

attics. Compensators may be used to physically separate the com-

bustion equipment from the building. These should be installed as near

as possible to the boiler in the flow, return and safety line. Also insulate

any braces or brackets, if installed, against sound/vibration transmis-

sion to the building. Detailed information on reducing noise emissions

from combustion equipment in heating systems can be found in the

Information Sheet No. 10 of the BDH (Bundesverband der Deutschen

Heizungsindustrie e. V.) [Germany].

8.10 Standard values for water quality

The service life of any boiler as well as that of the complete heating

system is influenced by the quality of the water. In any event, the cost

of a water treatment facility is less than the cost of repairing damage

to your heating system.

Observing the following requirements is necessary to safeguard your

warranty rights. The warranty excludes damage due to corrosion and

scaling.

The following is a summary of essential water quality requirements. A

mobile water treatment system can be hired from Viessmann for filling

and commissioning.

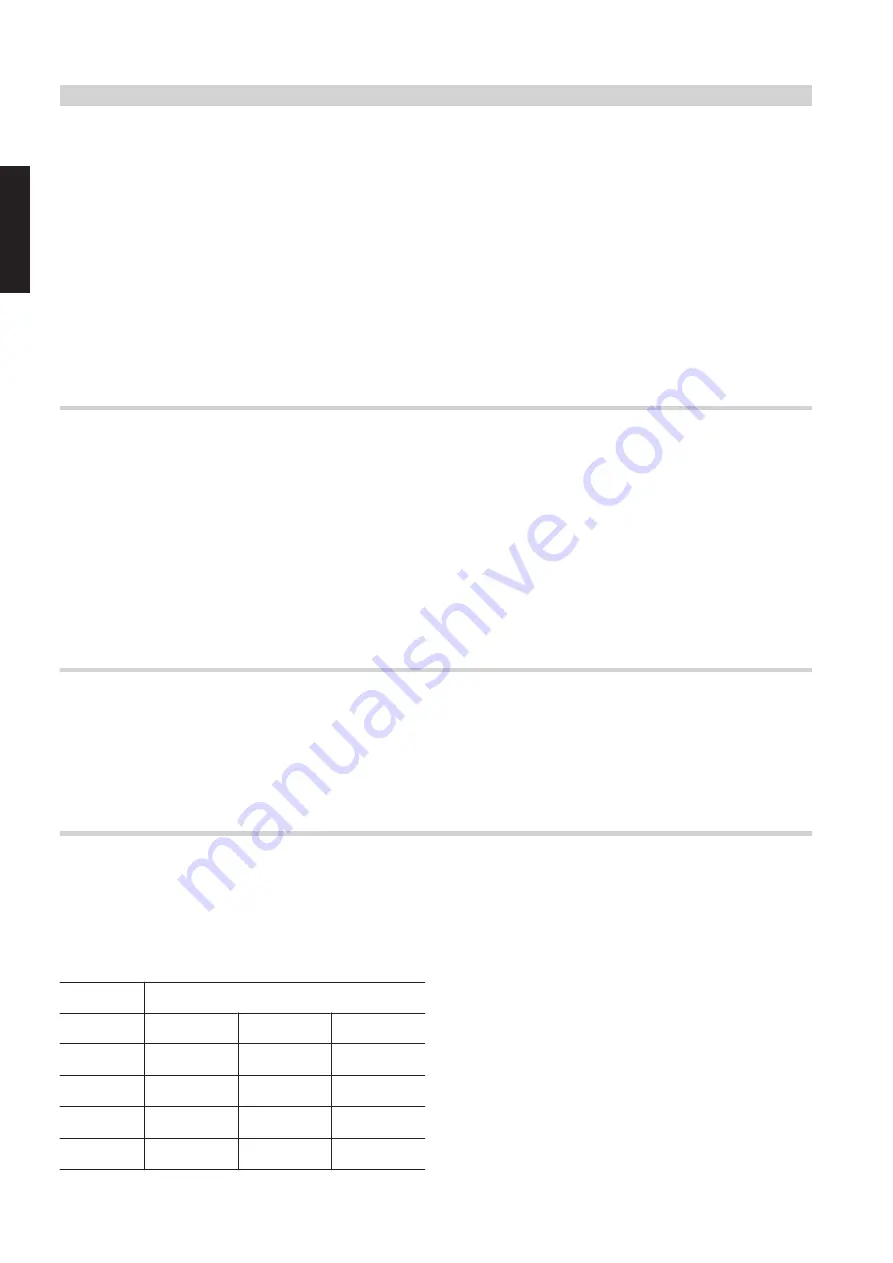

Heating systems with rated operating temperatures in excess of 100 °C (VDI 2035)

Prevent excessive scale build-up (calcium carbonate) on the heating

surfaces. For heating systems with operating temperatures up to

100 °C, VDI guideline 2035 sheet 1 "Prevention of heating system

damage – scaling in DHW and hot water heating systems" applies [in

Germany], together with the following standard values (see also the

full explanations in the original guideline).

Total permissible hardness of the fill and top-up water

Total heating

output

Specific system volume

kW

< 20 l/kW

≥ 20 l/kW to

< 50 l/kW

≥ 50 l/kW

≤ 50

≤ 3.0 mol/m

3

(16.8 °dH)

≤ 2.0 mol/m

3

(11.2 °dH)

< 0.02 mol/m

3

(0.11 °dH)

> 50 to ≤ 200

≤ 2.0 mol/m

3

(11.2 °dH)

≤ 1.5 mol/m

3

(8.4 °dH)

< 0.02 mol/m

3

(0.11 °dH)

> 200 to ≤ 600 ≤ 1.5 mol/m

3

(8.4 °dH)

≤ 0.02 mol/m

3

(0.11 °dH)

< 0.02 mol/m

3

(0.11 °dH)

> 600

< 0.02 mol/m

3

(0.11 °dH)

< 0.02 mol/m

3

(0.11 °dH)

< 0.02 mol/m

3

(0.11 °dH)

The standard values assume the following:

■ The volume of fill and top-up water will not exceed three times the

water content of the heating system during its service life.

■ The specific system volume is less than 20 l/kW heating output. In

multi boiler systems, apply the output of the smallest boiler.

■ All measures to prevent corrosion on the water side in accordance

with VDI 2035 sheet 2 have been implemented.

Soften the fill and top-up water in heating systems operating under the

following conditions:

■ The total of alkaline earths in the fill and top-up water exceeds the

standard value.

■ Higher fill and top-up water volumes are expected.

■ The specific system volume is greater than 20 l/kW heating output.

In multi boiler systems, apply the output of the smallest boiler.

Design information

(cont.)

48

VIESMANN

Gas condensing boilers

8

5822 449 GB