Componentry

33

Component Parts of the Venting System

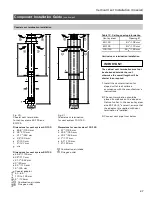

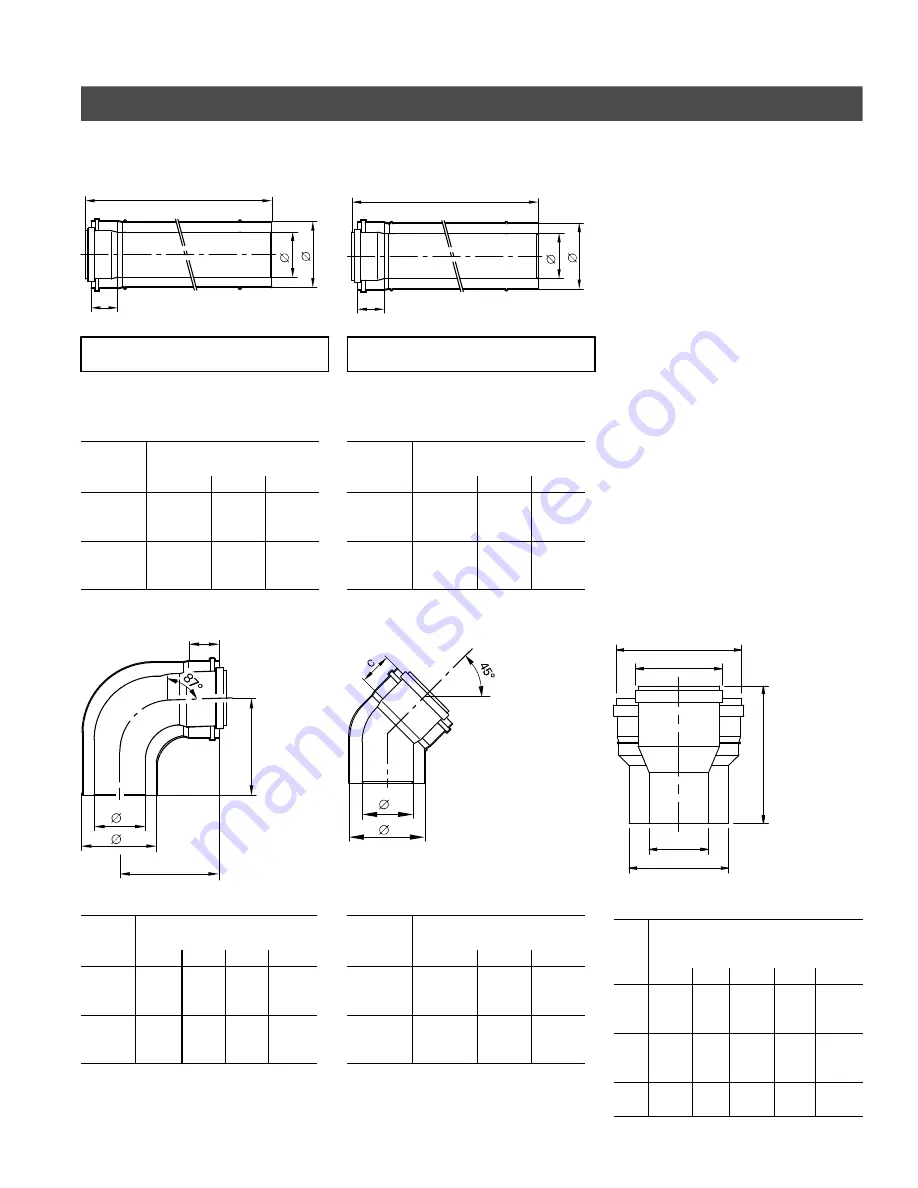

Straight pipe

(0.5 m)

(can be cut to length if required)

When cutting straight pipes to length, debur

and clean pipes.

Table 19.

Boiler

model

Dimensions

in.(mm)

a

b

c

WB1A

8-24

8-30

2.4(60)

2.4(60)

4(100)

4(100)

1.6(40)

1.6(40)

WB2

24/32

44/60

3(80)

4.3(110)

5(125)

6(150)

1.6(40)

1.6(40)

Straight pipe

(1 m)

(can be cut to length if required)

When cutting straight pipes to length, debur

and clean pipes.

Table 20.

Boiler

model

Dimensions

in.(mm)

a

b

c

WB1A

8-24

8-30

2.4(60)

2.4(60)

4(100)

4(100)

1.6(40)

1.6(40)

WB2

24/32

44/60

3(80)

4.3(110)

5(125)

6(150)

1.6(40)

1.6(40)

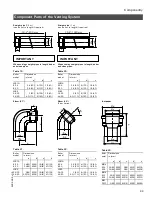

Elbow (87º)

Table 21.

Boiler

model

Dimensions

in.(mm)

a

b

c

d

WB1A

8-24

8-30

2.4(60)

2.4(60)

4(100)

4(100)

1.6(40)

1.6(40)

4.7(120)

4.7(120)

WB2

24/32

44/60

3(80)

4.3(110)

5(125)

6(150)

1.6(40)

1.6(40)

4.7(120)

6.7(170)

Elbow (45º)

(2 per carton)

Table 22.

Boiler

model

Dimensions

in.(mm)

a

b

c

WB1A

8-24

8-30

2.4(60)

2.4(60)

4(100)

4(100)

1.6(40)

1.6(40)

WB2

24/32

44/60

3(80)

4.3(110)

5(125)

6(150)

1.6(40)

1.6(40)

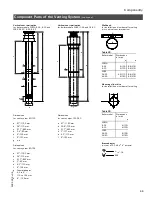

Increaser

Table 23.

Boiler

model

Dimensions

in.(mm)

a

b

c

d

h

WB1A

8-24

8-30

2.4(60)

2.4(60)

4(100)

4(100)

3(80)

3(80)

5(125)

5(125)

5.4(138)

5.4(138)

WB1A

8-24

8-30

2.4(6)

2.4(60)

4(100)

4(100)

4.3(110)

4.3(110)

6(150)

6(150)

5.2(133)

5.2(133)

WB2

24/32

3(80) 5(125)

4.3(110)

6(150)

6.5(165)

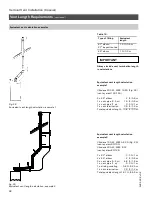

5

2

8

5

2

6

8

v

3

.8

b

c

19.7”/500 mm

a

IMPORTANT

b

c

39.4”/1000 mm

a

IMPORTANT

b

a

d

d

c

b

a

Ød

Øc

h

Øa

Øb

Summary of Contents for Vitodens 100-W WB1A-24

Page 78: ...78 5285 268 v3 8 ...

Page 79: ...79 5285 268 v3 8 ...