56

5608 741 - 04

Vitodens Rigid and Flex Venting Systems Installation

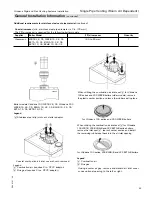

General Installation Information

(continued)

Approved materials for single pipe vent system

Part

Material

Certified to Standards

Applicability

Exhaust pipe and fitting

Stainless steel UL1738

”Venting systems for gas-burning appliances,

Categories II, III, IV”

U.S.A./Canada

ULC S636

”standard for Type BH gas venting systems”

CPVC

UL1738

”Venting systems for gas-burning appliances,

Categories II, III, IV”

ULC S636

”standard for Type BH gas venting systems”

Class IIB 90°C

PP(s)

UL1738

”Venting systems for gas-burning appliances,

Categories II, III, IV”

ULC S636

”standard for Type BH gas venting systems”

Class IIC 110°C

Pipe cement, primer (for

exhaust pipe and fitting)

CPVC

ULC S636

”Standard for Type BH gas venting systems”

Class IIB 90°C

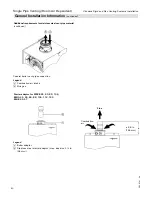

Single Pipe Venting (Room Air Dependent)

CAUTION

Do not use cellular (foam) core pipe material to vent the

Vitodens boiler.

CAUTION

Do not use PVC material in exhaust system.

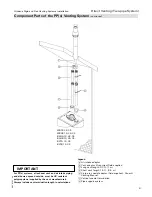

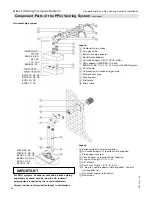

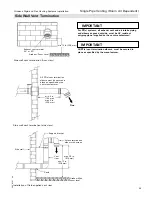

Support system

The venting system must be securely supported by a

support system suitable for the weight and design of the

materials employed.

The Vitodens boiler is not designed to support the weight

of the venting system.

Use supports to transfer the weight of an installation

to the building structure. There are different types of

supports available and their capacity varies with each

type and diameter.

The following support types are available at your local

vent material supplier...

anchor plate

wall support

roof support

floor support

suspension band (hanger).

In addition to the support types listed, mounting clips can

be used to support the weight of the venting system.

Contact your vent material supplier for more information

specific to your installation.

Follow the installation instructions supplied by the special

venting manufacturer.