59

5608 741 - 04

Vitodens Rigid and Flex Venting Systems Installation

Single Pipe Venting (Room Air Dependent)

General Installation Information

(continued)

Additional requirements for stainless steel vent pipe material

(continued)

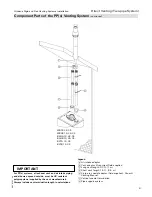

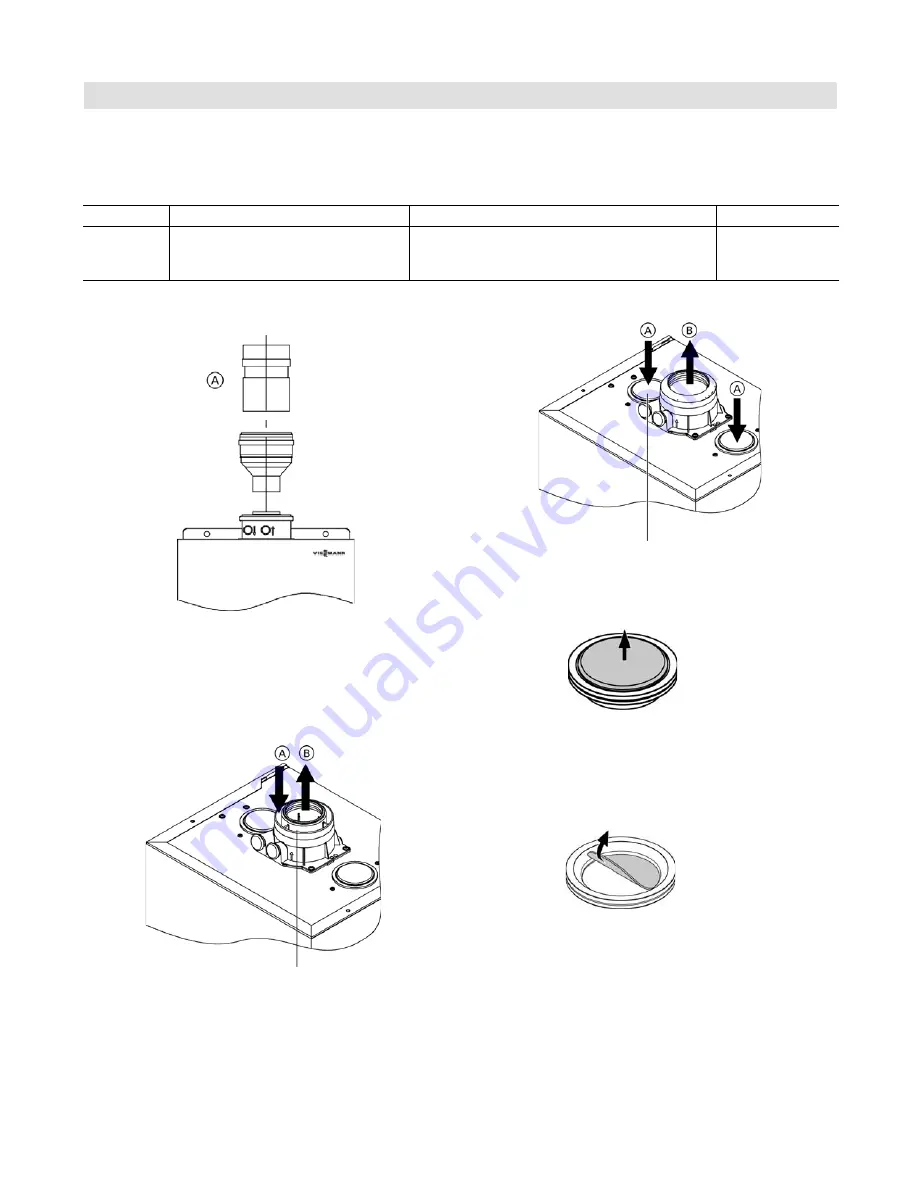

Coaxial increaser

[min. stainless steel pipe diameter is 3 in. (76 mm)]

The PP(s) increaser is required for the following boiler models.

Supplier

Boiler Model

PP(s) increaser

Quantity

Viessmann

WB1B 26, 35, WB2B 19, 26, 35

B2TA 19, 35, B2HA 19, 28, 35,

B2TB 19, 35, B2HB 19, 26, 35

(60 to 80 mm)

1

Legend

A

Stainless steel slip joint vent starter adaptor

Boiler models Vitodens 100 WB1B 26, 35, Vitodens 200

WB2B 19, 26, 35, B2HA 19, 28, 35, B2HB 19, 26, 35,

B2TA 19, 35, B2TB 19, 35,

Coaxial combustion air inlet cover shown removed.

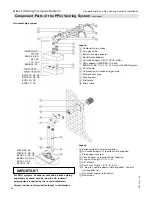

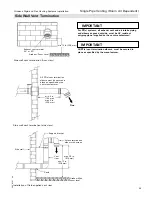

Legend

A

Combustion air (requires 2 in. CPVC adaptor)

B

Flue gas (requires 2 inc. CPVC adaptor)

Legend

A

Combustion air

B

Flue gas

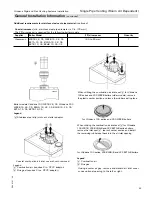

When utilizing the combustion air inlet seal

A

for Vitodens

100 WB1B, 200 B2HA/B and 222 B2TA/B series boilers,

remove the inlet seal

A

, tear out center section and install

the remaining rubber seal back into the air inlet opening.

for Vitodens 100 series and 200 WB2B boilers

for Vitodens 100 series, 200 B2HA/B and 222 B2TA/B boilers

When utilizing the combustion air inlet seal

A

for Vitodens

100 series and 200 WB2B boilers (older models), remove

the plastic center section and leave the rubber seal in place.

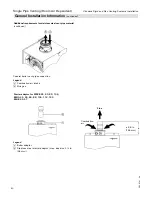

If using annular air gap, remove and discard air inlet cover

or use optional opening to the left or right.