36

5600 332 v1.3

Vitodens 100-W, WB1B Installation & Service

Installation Examples

Connections

General

The schematics on the following pages are to be seen as

guidelines only. They further do not display all system

varieties, safety devices, or concepts possible. Specific

system layouts may be further discussed with the local

Viessmann sales representative office.

Clearances

A minimum of 2” (51 mm) circumferential clearance from

non-insulated hot water pipes to combustible construction

must be maintained. In cases where the pipes are insulated

with pipe insulation of appropriate and sufficient thickness

and insulation values, the above clearance may be

reduced to 0” (refer to local gas codes).

Model WB1B

26

35

∆

t

Output Btu/h

83,000

108,000

30º F rise (GPM)

5.5

----

35º F rise (GPM)

4.7

6.2

40º F rise (GPM)

4.2

5.4

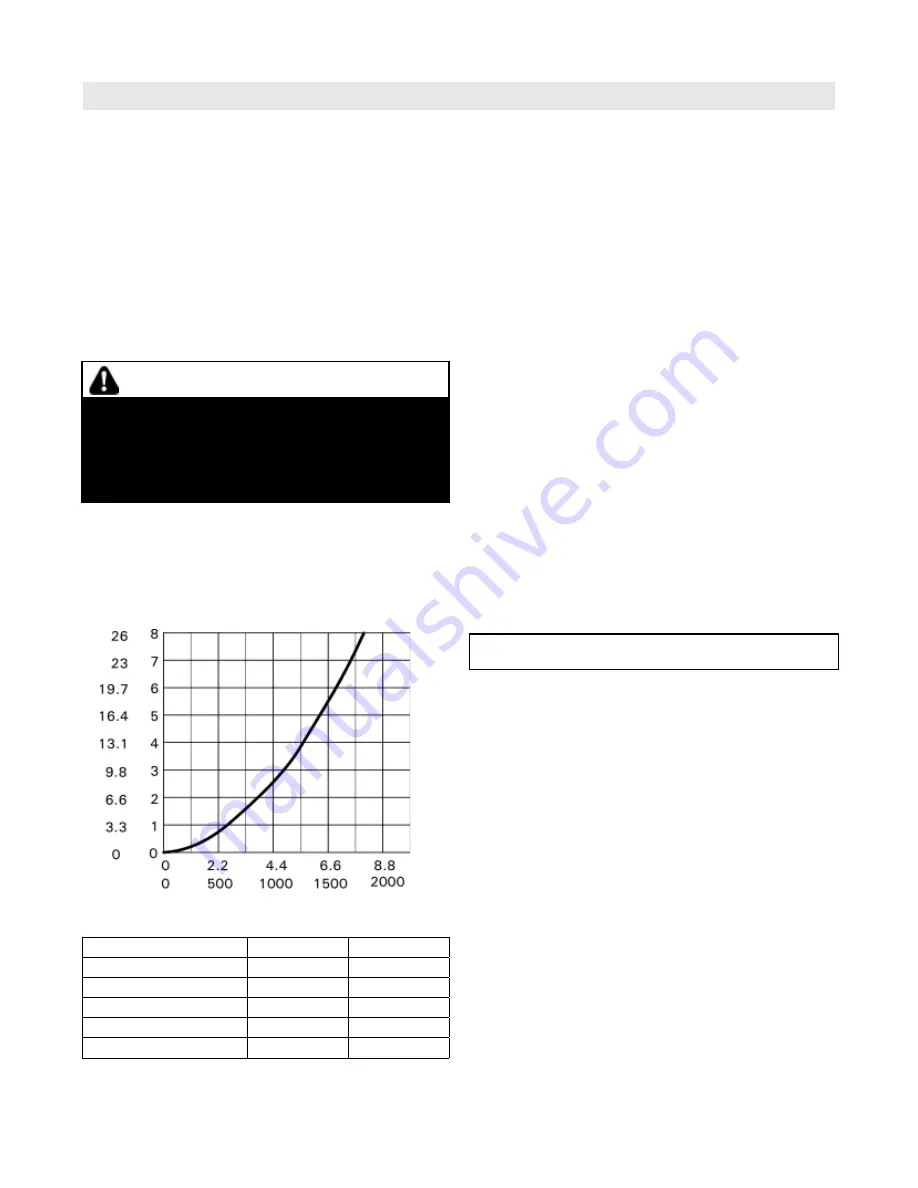

Pressure drop (primary circuit) of Vitodens 100-W

The Vitodens 100-W is designed only for closed loop,

forced circulation hot water heating systems.

Heating circuit pumps

Recommended heating pumps with Vitodens 100-W,

WB1B 26, 35.

g

Grundfos 15-58 (3-speed)

g

Taco 00R

or equivalent

Refer to the graph above for the proper waterside boiler

friction loss calculations.

Pump selection must be based on accurate system flow

and pressure drop calculations (incl. DHW sizing).

A low-loss header

must

be used when the

system

flow

rate exceeds the maximum (or minimum) flow rate of

the Vitodens 100-W boiler. An alternative method may

be used, such as primary secondary piping using closely

spaced tees.

A low-loss header offers additional benefits not provided

by a pair of closely spaced tees. Viessmann strongly

recommends and prefers the use of a low-loss header

over closely spaced tees.

Use standard friction loss method for pipe sizing. Observe

boiler maximum and minimum flow rate limitations.

If system flow rate exceeds boiler maximum flow rate

(as stated on page 86) or if system flow rate is unknown,

Viessmann strongly recommends the installation of a low-

loss header. See page 49 for low-loss header information

or refer to the Vitodens Venting System Installation

Instructions.

Typical system flow rates

ft. m

Pressure Drop

Flow rate

USGPM

L/h

CAUTION

For underfloor heating applications, an additional

immersion or strap-on aquastat must be installed in the

low temperature underfloor loop (downstream of the

mixing valve) to de-energize the pump and/or boiler

to prevent overheating. High water temperatures can

damage concrete slabs.

IMPORTANT