144

6.

Check the connections on the heat-

ing water and DHW side for contam-

ination and scaling; if required,

replace the plate heat exchanger.

7.

Install in reverse order using new

gaskets.

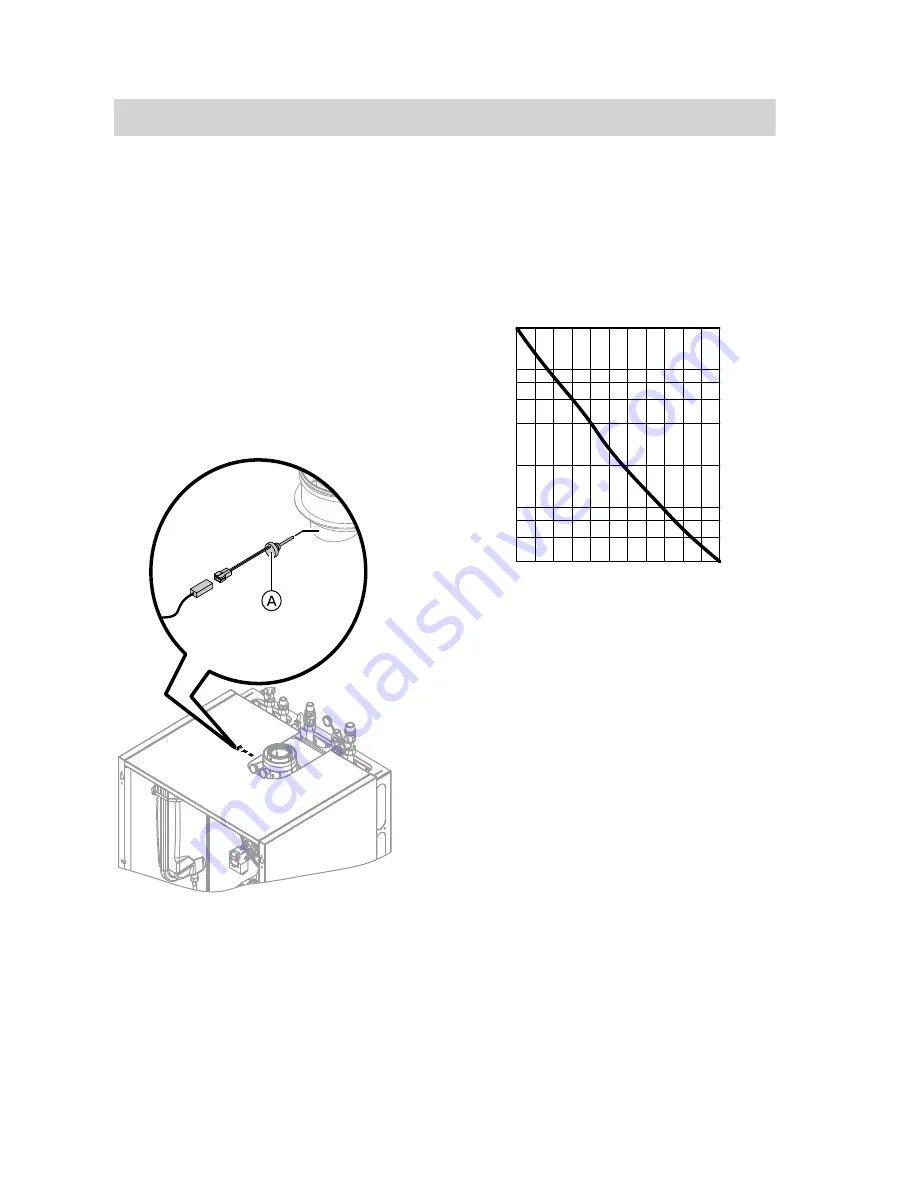

Checking the flue gas temperature sensor

The flue gas temperature sensor locks

out the boiler when the permissible flue

gas temperature is exceeded. Reset the

interlock after the flue system has cooled

down by pressing reset button

R

.

10

1

10 30 50 70 90 110

Temperature in °C

0.4

0.6

0.8

2

4

6

8

20

Resistance in k

Ω

Sensor type: NTC 10 kΩ

1.

Pull leads from flue gas temperature

sensor

A

.

2.

Check the sensor resistance and

compare it with the curve.

3.

Replace the sensor in the case of

severe deviation.

Fault "A3" during commissioning

During commissioning, the control unit

checks whether the flue gas temperature

sensor is correctly positioned.

If the flue gas temperature sensor is not

positioned correctly, commissioning is

cancelled and fault message A3 is dis-

played.

1.

Check whether the flue gas temper-

ature sensor is correctly inserted.

See previous diagram.

Troubleshooting

Repair

(cont.)

5773 216 GB

Summary of Contents for Vitodens 222-F B2TA series

Page 12: ...12 2 5 1 4 2x 3 Installing the boiler Removing the front panels 5773 216 GB...

Page 13: ...13 1 2 SW17 Installing the boiler Siting and levelling the boiler 5773 216 GB Installation...

Page 31: ...31 4 1 5 2 2x 3 Installing the boiler Fitting the front panels 5773 216 GB Installation...

Page 194: ...194 5773 216 GB...

Page 195: ...195 5773 216 GB...