35

A

Additives for fuel oil.................................................... 34

Air damper position...................................................... 8

Air damper servomotor, checking the settings............. 8

B

Biofuels...................................................................... 34

Burner cleaning.......................................................... 10

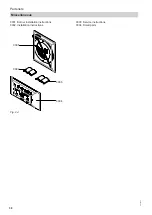

Burner control unit

– Burner fault flowchart.............................................. 16

– Function and fault indications of the signal indicator

(LED).......................................................................15

– Program sequence during commissioning.............. 15

Burner fault flowchart................................................. 16

C

Cleaning the oil pump filter and replacing it if required..

Combustion improvers............................................... 34

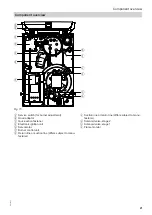

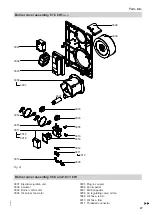

Component overview................................................. 21

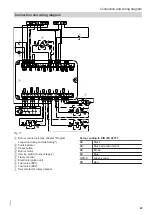

Connection and wiring diagram..................................23

D

Diagnosis

– Faults with flash code indication............................. 18

– Faults without flash code indication........................ 19

F

Flash code..................................................................18

Flowchart, burner faults..............................................16

Fuel oil

– Additives..................................................................34

– Quality..................................................................... 34

I

Ignition air setting......................................................... 8

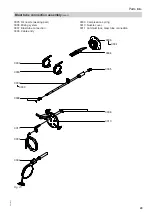

Ignition electrodes, checking and adjusting............... 12

N

Nozzle replacement....................................................11

O

Oil pressure, adjusting................................................. 6

Operating and service documents............................. 14

P

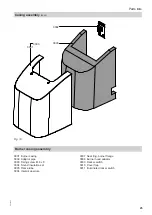

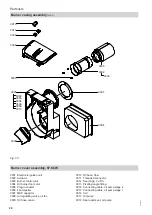

Parts lists....................................................................24

R

Report........................................................................ 31

S

Specification.........................................................32, 33

Standard values for burner adjustment...................... 33

System commissioning................................................ 6

V

Vacuum, checking........................................................ 6

Keyword index

Keyword index

5831447