23

5603 880 - 03

Vitoflex 300-RF Service & Maintenance

Troubleshooting

Checking the Inside of the Boiler Door

Checking the inside of the boiler door can indicate whether the fibre glass seal is properly applied. If the seal is not

properly applied, higher levels of CO gas can form. Checking the inside of the door can also indicate whether the

guide tube is indicating increased wear. This is a danger especially at higher temperatures.

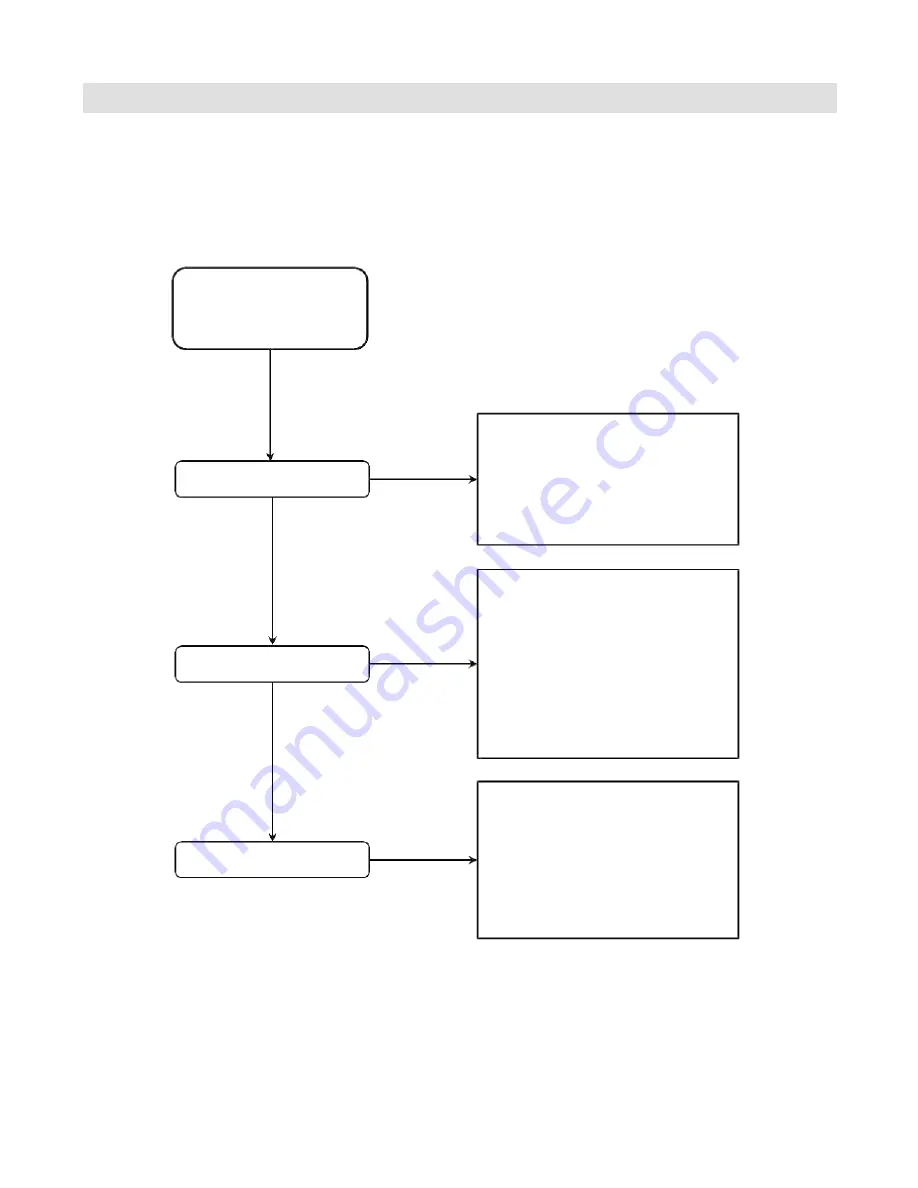

Checking the inside

of the boiler door

Check guide tube

Check boiler door seal

Check fireclay boiler door

Check guide tube for deformation

(possible cause of deformation:

Overheating

If there is increased wear

of the fireclay, perform check (see section

checking for increased wear of Fireclay)

Check guide tube for wear

Seal must fit properly and be caulked

Procedure if a seal is leaking

Replace ceramic packing of the seal,

check by means of impression test

that the whole surface of the seal lies

on the ceramic packing, increase seal

contact pressure in RF-400/540 with

the screws outside on the door

Check fireclay erosion

The formation of cracks and spalling

outside the glass fibre packing only

constitutes an optical imperfection

Complaints must be made in the event

of fireclay erosion inside the glass fibre

packing from ~ 3

d

”(80 mm)