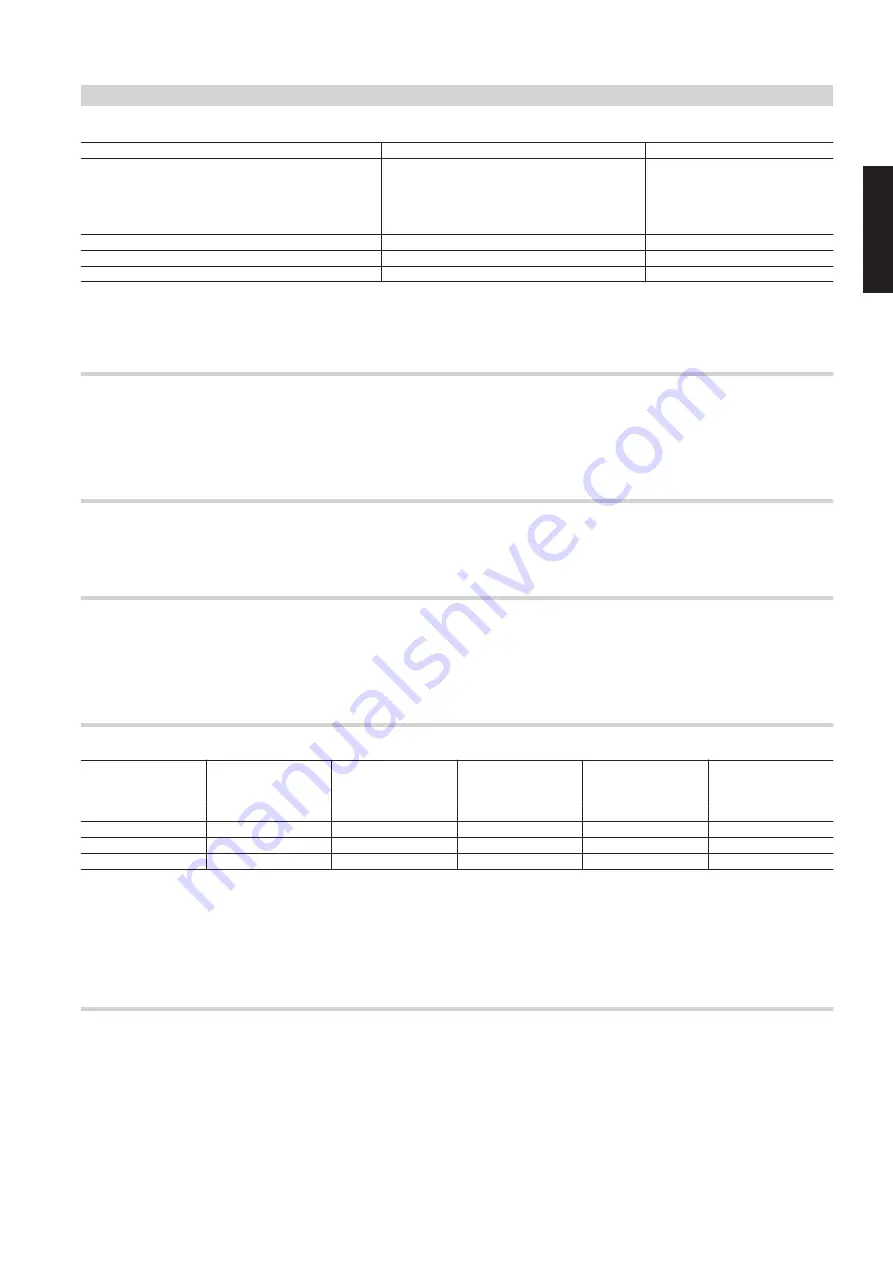

Requirement

ENplus-A1

EN ISO 17225-2 quality A1

Ash softening temperature

This value is only binding for pellets certified to ENplus.

It indicates the temperature at which the wood ash is

deformed and can therefore cause fusions in the com-

bustion chamber.

°C

≥ 1200

–

Chlorine content, free from water

m-%

≤ 0.02

Cl0.2

Sulphur content, free from water

m-%

≤ 0.04

S0.04

Nitrogen content, free from water

m-%

≤ 0.3

N0.03

m-% = percentage by mass

Note

EN 14961-2 was superseded by the new standard EN ISO 17225-2

in September 2014. It describes the essential properties of wood pel-

lets.

Pellet quality characteristics

Good wood pellets:

■ Smooth, shiny surface

■ Uniform length

■ Low proportion of dust

■ Sink in water

Low quality wood pellets:

■ Cracked rough surface

■ Widely varying length

■ High proportion of dust

■ Float in water

Types of pellet delivery

In their loose form, wood pellets are transported by silo tanker and

pumped into the storage room via a hose system.

Careful handling of wood pellets ensures a low proportion of dust,

trouble-free boiler charging and a constant heating output by the

solid fuel boiler.

1.3 Principles of woodchip combustion for generating heat

What are woodchips?

Woodchips are made from 100 percent natural wood from forests

and plantations. This raw material comes from tree trunks or

branches.

The wood is then processed with high speed cutting tools in accord-

ance with EN ISO 17225.

Definition of woodchip size classes according to EN ISO 17225-4

Size class

Main percentage (at

least 60 % of the

mass), a)

Fine fraction

(≤ 3.15 mm)

Coarse fraction (in

brackets particle

length)

Maximum particle

length, b)

Maximum cross-sec-

tion area of the coarse

fraction, b) c)

Size in mm

In % of the mass

In % of the mass

in mm

In cm

2

P16S

3.15 to 16

≤ 15 %

≤ 6 (> 31.5 mm)

≤ 45

≤ 2

P31S

3.15 to 31.5

≤ 10 %

≤ 6 (> 45 mm)

≤ 150

≤ 4

P45S

3.15 to 45

≤ 10 %

≤ 10 (> 63 mm)

≤ 200

≤ 6

a) The number in the size class refers to the maximum particle size in the main percentage. The particles have to pass through a strainer

with a circular mesh (ISO 17827-1 standard), in which the sieve apertures are of the specified size for the size class. The lowest possible

property class should be specified.

b) Only determine the length and cross-sectional area of particles in the coarse fraction. In a sample of about 10 l 2 pieces at the most can

exceed the maximum length if the cross-sectional area is < 0.5 cm

2

.

c) To measure the cross-sectional area, you are advised to use a transparent set square, arrange the particles at right angles behind the set

square and use a cm

2

grid to estimate the maximum cross-sectional area of these particles.

Woodchip requirements

For combustion in the solid fuel boiler, use woodchips of size class

P31S that have the following properties:

■ Max. coarse fraction of 6 % (> 45 mm)

■ Max. cross-section of 4 cm²

■ Max. length of 15 cm (1 % up to 45 mm)

■ Moisture content (see product description)

Principles of wood combustion

(cont.)

VITOFLEX 300-UF

Viesmann

9

5682428

1