Appendix

31

Post-Installation ...

Start-up information

Start-up/Service Instructions

of boiler and control

Service Binder

1.

File all Parts Lists, Operating and

Service Instructions into the Service

Binder.

2.

Install a protective hanging case near

the boiler and store the Service

Binder in this location.

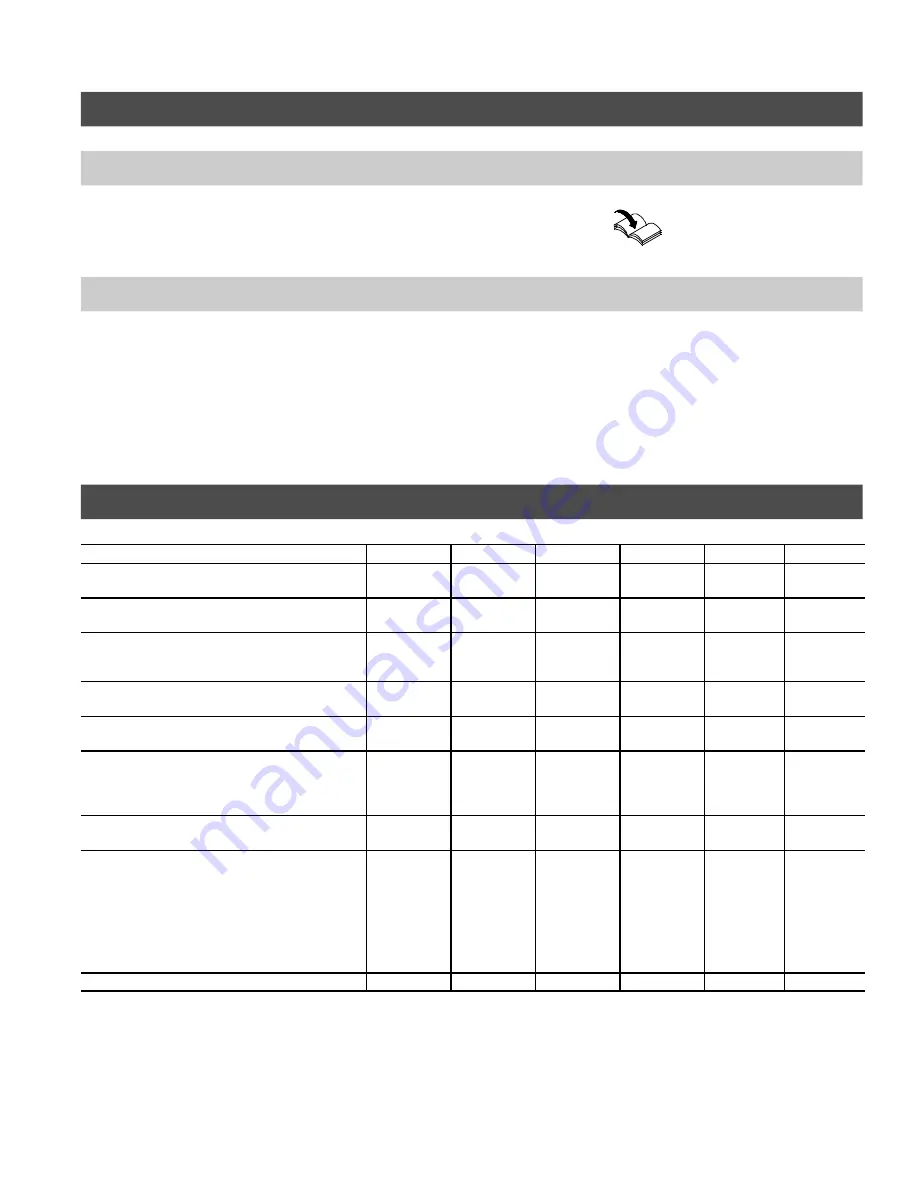

Technical Data

Boiler Model

Model No.

GS1-22

GS1-29

GS1-35

GS1-42

GS1-48

GS1-60

CSA input

MBH

kW

90

26

115

34

145

42

165

48

190

56

240

70

CSA output

DOE heating capacity

MBH

kW

76

22

98

29

123

36

140

41

161

47

203

60

Min. gas supply pressure

Natural gas

LPG

“ w.c.

“ w.c.

5

11

5

11

5

11

5

11

5

11

5

11

Max. gas supply pressure

*1

(flow)

“ w.c.

14

14

14

14

14

14

Max. operating pressure

(water)

psig

60

60

60

60

60

60

Boiler connections

Boiler supply and return

Safety supply

Drain valve

Ø” (male thread)

Ø” (male thread)

Ø” (male thread)

1½

1½

¾

1½

1½

¾

1½

1½

¾

1½

1½

¾

1½

1½

¾

1½

1½

¾

Gas supply connection

Ø” (tapered male

thread)

½

½

½

½

½

½

Flue gas

*2

Temperature (gross)

Mass flow rate

– with natural gas

– with LPG

°F

°C

lbs/h

kg/h

lbs/h

kg/h

223

106

161

73

148

67

216

102

216

98

209

95

235

113

236

107

209

95

266

130

231

105

223

101

228

109

342

155

322

146

252

122

353

160

337

153

Vent pipe collar

outside

Ø”

5

6

6

6

7

7

*1

If the gas supply pressure is higher than the maximum permissible value, a separate gas regulator must be installed upstream of the

boiler system.

*2

Measured flue gas temperature after dilution air with combustion air temperature of 68°F / 20°C.

5

1

6

7

4

6

3

v

1

.3

Summary of Contents for Vitogas 100 GS1 Series

Page 35: ...35 5167 463 v1 3 ...