Vitosol 100-FM/200-FM Installation, Operating and Service

29

5786 604 - 02

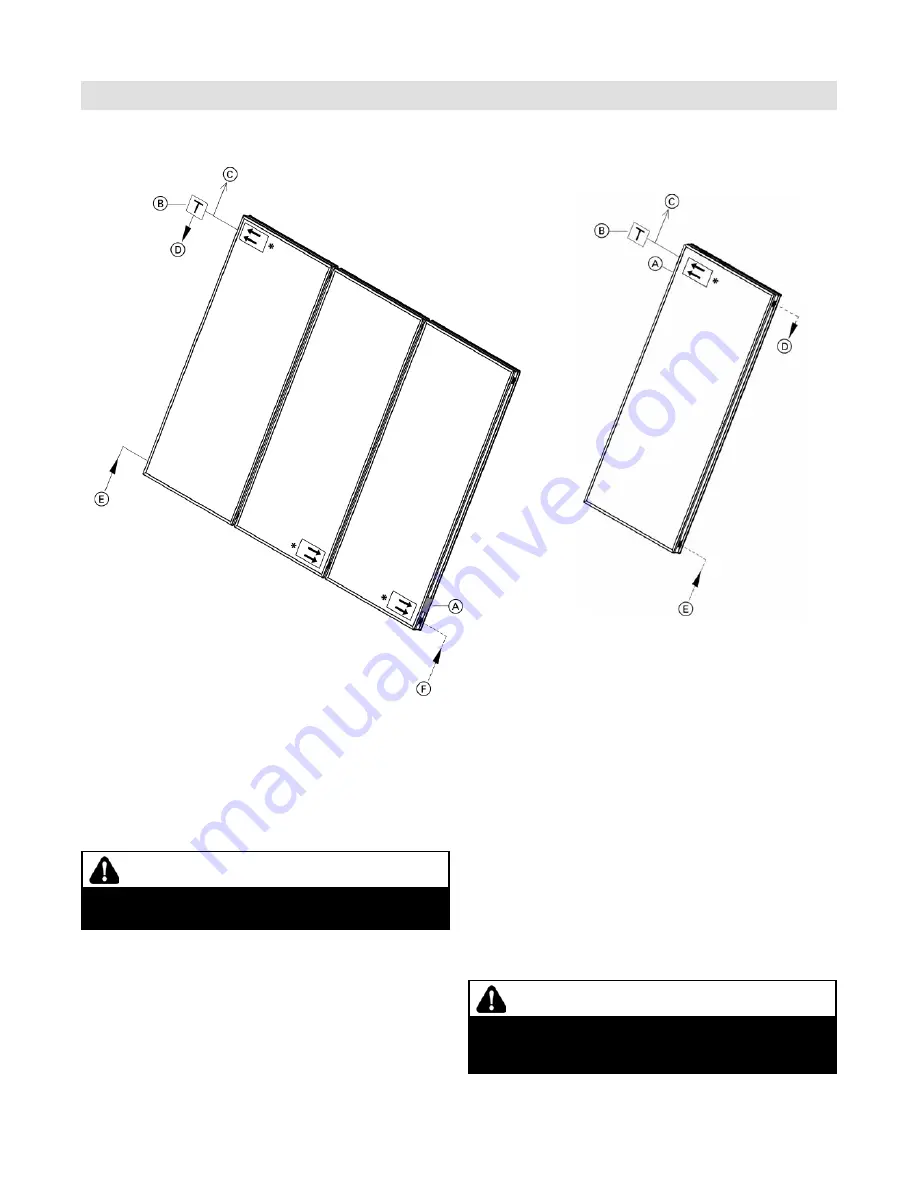

Supply and Return Piping Configuration

Arrow directions are to ensure balanced flow throughout

the collectors.

If the collectors are not connected as shown above, it

could also result in:

- Collector temperature sensor not sensing the hottest

collector temperature

- The fluid flow through the collector array may be

imbalanced.

- A decrease of the efficiency of the collectors.

Legend

A

Rating plate (must be on the outside of the outer

collectors)

B

Collector temperature sensor location

C

Air vent location

D

Supply pipe from collector

E

Return pipe to collector

F

Alternate location for return pipe to collector

CAUTION

Viessmann strongly recommends not removing the

cover foil from the collectors until after initial start-up

in order to prevent overheating.

CAUTION

Arrows on the first and last collector in a series must

point towards the outside.

Note:

This piping configuration requires 1x short

connecting pipe on page 7.

* must be ordered separately from Viessmann.

Multiple collector array

Single

collector

array

Hydronic Connections