12

6167217 GB

Operation (cont.)

Faults

Maintenance

Venting

Caution

Air in the water installation may damage

the appliance.

Vent the system after working on the

appliance or the water installation.

1. Switch off the power supply, e.g. at the

separate fuse or a mains isolator.

2. Open and close the hot water tap several

times to vent the water installation until a

constant, even flow of water is achieved.

3. Turn the rotary switch to the required

temperature.

4. Switch on the power supply.

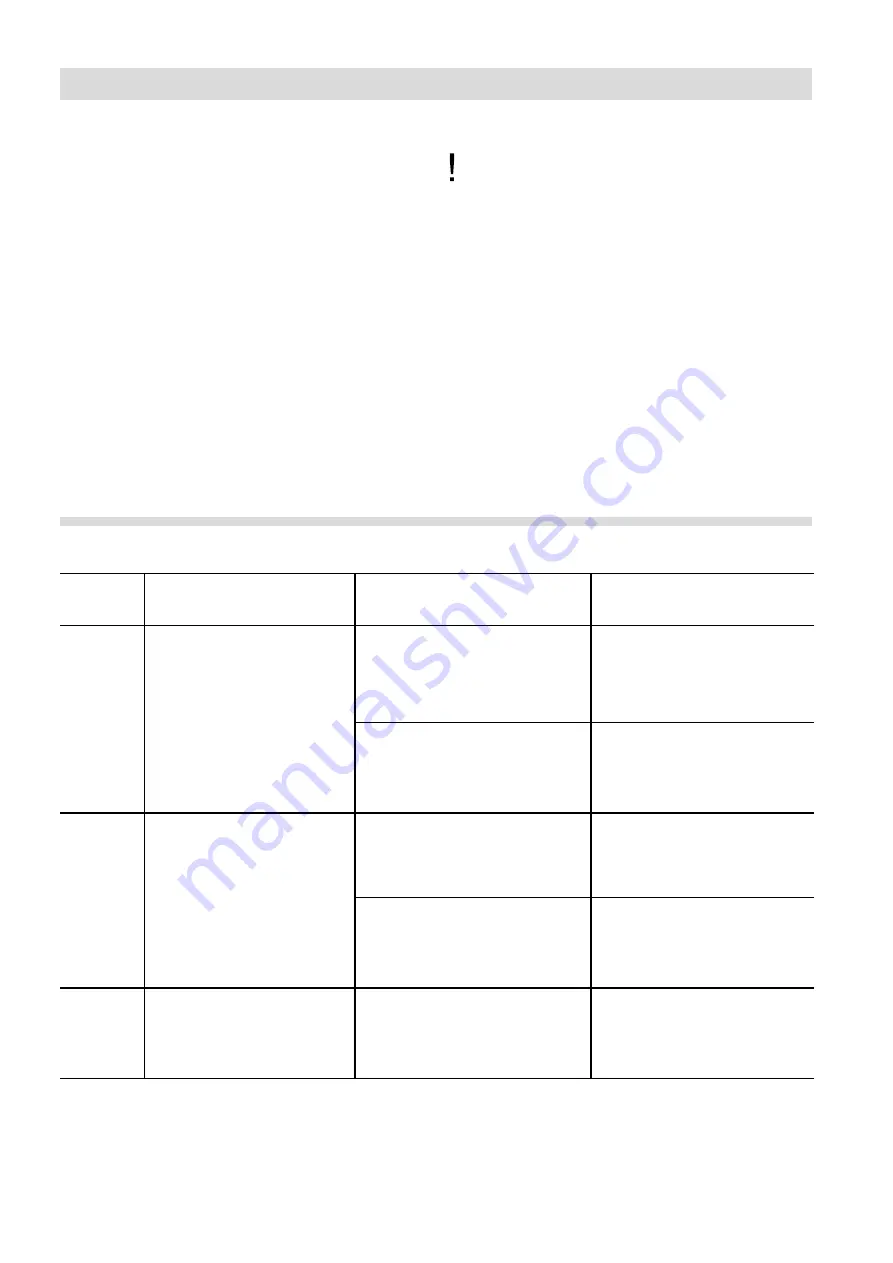

No.

Fault

Background

Remedy

1.

The appliance is not

heating the water

and the LED is not

illuminated.

Power supply fault.

Check the fuses.

Fault with the rotary

temperature switch.

Replace the rotary

temperature switch.

(Heating contractor)

2.

The appliance is not

heating the water and

the LED is illuminated.

Fault with the heating

module.

Replace the appliance.

(Heating contractor)

Fault with the temperature

limiter.

Switch on the temperature

limiter or replace it.

(Heating contractor)

3.

The appliance is heating

the water and the LED is

not illuminated.

Fault with the LED.

Replace the LED.

(Heating contractor)