7

VFS/US

0-10V

PWM1

22

V40

S10

20

19

S9

18

17

0-10V

PWM2

24

0-10V

PWM1

22

0-10V

PWM3

26

0-10V

PWM4

28

30

32

31

+VBus-

2

1

S1

4

3

S2

6

5

S3

8

7

S4

10

9

S5

12

11

S6

14

13

S7

16

15

S8

Temp. Sensor

Flow Rotor

1

1

1

1

R1

L`

N

R4

R4

L`

L

R2

R3

B

A

C

D

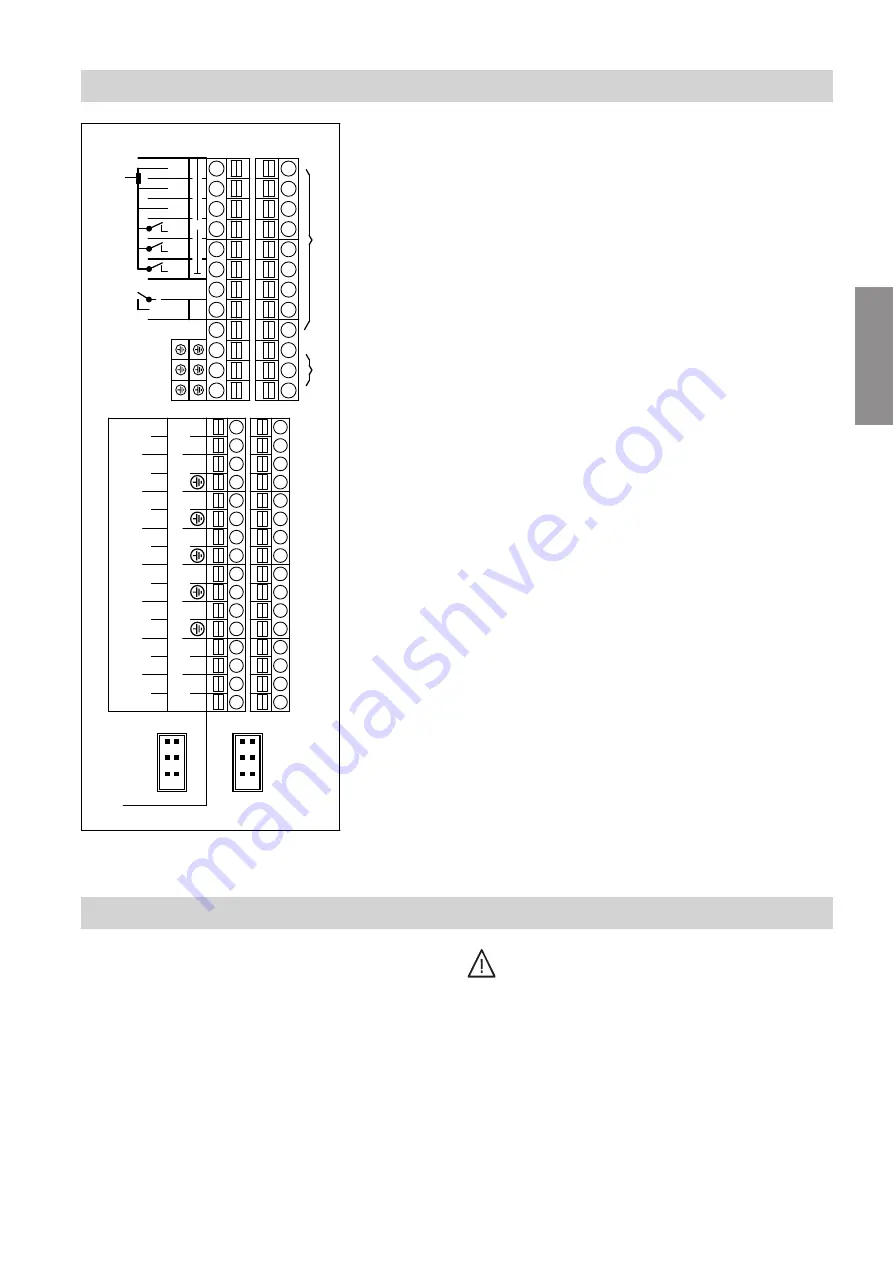

Fig.2

A

Control unit wiring chamber

B

Fuse 4 A (slow)

C

Terminals, neutral conductors

D

PE terminals

230 V connections

R1 to R3 Semi-conductor relay

(R1 to R3 suitable for speed control)

R4

Potential-free relay

LV terminals

VBus

VBus to connect the control units in

a cascade

PWM1 to PWM4 PWM signals for pumps at R1 to R3

S1 to S8

Temperature sensors

Routing cables

!

Please note

Contact with hot components causes cable

damage.

After installation, cables must not come into con-

tact with hot components.

■

Types PBS, PBM and PBL:

Route cables to the outside through the rear thermal

insulation (cut-out in the upper part).

■

Types PZS and PZM:

Route the cables through the hole for the return on

the heating water side (in the support panel and the

rear thermal insulation).

Connecting the pumps

Pump to be connected, individual appliance:

■

Secondary pump (DHW circulation pump) from the

DHW circulation set, accessories

Connect the connecting cable to the pump using

plugs and connect in the control unit; see diagram.

Pump to be connected, cascade:

■

Secondary pump (DHW circulation pump), accesso-

ries

Recommended cable: 3-core with a cross-section of

0.75 mm

2

Danger

Incorrect core allocation can result in serious

injury and damage to the appliance.

Take care not to interchange cores "L'", "R2"

and "N".

Colour coding to IEC 60 757:

BN

Brown: L' and PWM2 24

BU

Blue: N and PWM2 PE

GNYE Green/yellow: PE

Installation sequence

Overview of electrical connections

5517 095 GB

Installation

Summary of Contents for VITOTRANS 353

Page 50: ...50 5517 095 GB ...

Page 51: ...51 5517 095 GB ...