Safety instructions

2

Safety Instructions

Safety, Installation and Warranty Requirements

Please ensure that these instructions are read and understood before commencing installation and operation. Failure to comply

with the instructions listed below and details printed in these instructions can cause

product/property damage

,

severe personal

injury

, and/or

loss of life

. Ensure all requirements below are understood and fulfilled (including detailed information found in manual

subsections).

Licensed professional heating

contractor

The installation, adjustment, service,

and maintenance of this equipment

must be

performed by a licensed

professional heating contractor.

Please see sections

entitled “Safety” and

“Important Regulatory and

Installation Requirements”.

Product documentation

Read all applicable documentation

before commencing installation. Store

documentation near boiler in a readily

accessible location for reference in the

future by service personnel.

For a listing of

applicableliterature, please

see section entitled

“Important Regulatory and

Installation Requirements”.

Advice to owner

Once the installation work is complete,

the heating contractor must familiarize

the system operator/ultimate owner

with all equipment, as well as safety

precautions/requirements, shut-down

procedure, and the need for

professional service annually before the

heating season begins.

Warranty

Information contained in this and

related product documentation must be

read and followed.

Failure to do so

renders warranty null and void.

Safety Terminology

One or more of the following terms are used throughout this manual to bring attention to the presence of potential hazards or

important product information.

Please heed the advice given!

Helpful hints for installation, operation or

maintenance which pertain to the

product.

5

3

0

3

2

6

9

v

1

.3

Indicates an imminently hazardous

situation which, if not avoided, will

result in death, serious injury or

substantial product/property damage.

DANGER

Indicates an imminently hazardous

situation which, if not avoided, could

result in death, serious injury or

substantial product/property damage.

WARNING

Indicates an imminently hazardous

situation which, if not avoided, may

result in minor injury or

product/property damage.

CAUTION

IMPORTANT

Summary of Contents for Vitotronic 300 KW3

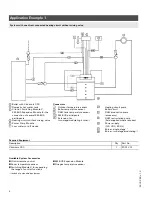

Page 25: ...Appendix 25 5303 269 v1 3...

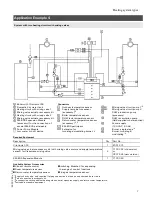

Page 26: ...Appendix 26 5303 269 v1 3...

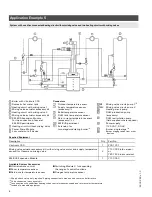

Page 27: ...Appendix 27 5303 269 v1 3...