11

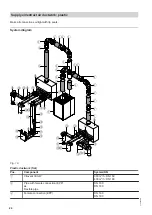

Information regarding the operation of the Vitovent

in conjunction with open flue combustion equip-

ment

■

On-site safety equipment

must

be installed that will

switch off the ventilation unit when there is negative

pressure inside the room.

■

The relevant flue gas inspector

must

give his/her

approval [check local regulations].

■

Frost protection for the countercurrent heat

exchanger is ensured by means of the integral pre-

heater coil. For operation with even lower outside

temperatures, provide an additional external electric

preheater coil (accessories) or a geothermal heat

exchanger (on site) in the outdoor air duct.

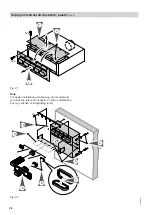

Extractor hoods, extracting tumble dryers and the

Vitovent

!

Please note

The simultaneous operation of extractor hoods

or extracting tumble dryers and the ventilation

unit in interconnected rooms results in negative

pressure inside the room.

Never

link extractor hoods or extracting tumble

dryers into the ventilation unit ductwork.

Set up kitchen extractor hoods as

recirculating

extractors

, which is more energy efficient.

Never connect existing

extractor hoods

to the extract

air duct of the mechanical ventilation system for the

following reasons:

■

Hygiene, contamination:

grease deposits in the extract air system

■

Noise from the supply air valves:

Extractor hoods operate with a substantially greater

air flow rate (> 300 m

3

/h) than the ventilation unit.

The generated negative pressure creates a "short

circuit" inside the system, as the amount of differen-

tial air must be made up by the ventilation ductwork.

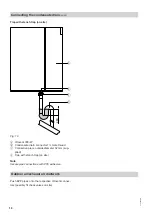

Connect extractor hoods via a coaxial exhaust air sys-

tem to enable the differential air volume to be replen-

ished.

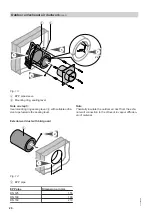

Provide an interlock for the extractor when using an

extractor hood in conjunction with open flue combus-

tion equipment: See chapter "Open flue combustion

equipment and Vitovent"

Siting

(cont.)

5793 589 GB