8

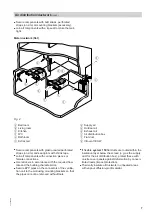

Supply air/extract air valves

■

Arrange the supply air and extract air valves in the

room geometry so that the air is routed as directly as

possible between rooms that are ventilated and

those from which air is extracted. At the same time,

ensure as broad a flow pattern as possible through

the entire room.

■

Max. distance to the ceiling in the case of wall

mounting: 300 mm

Air routing between rooms

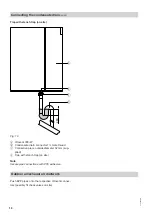

■

Create an interconnected room air supply between

the rooms to be ventilated and those from which air

is to be extracted.

■

For this, a gap under doors into the apartment is suf-

ficient. The correlation between gap height and air

flow rate is shown in DIN 1946-6 (see technical

guide).

■

Where internal doors are tightly sealed, provide on-

site noise attenuated overflow vents in the internal

walls or in part of the door.

Preventing flow noise and pressure drop

■

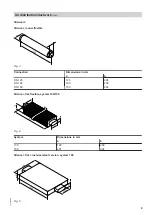

Install air distribution boxes close to the ventilation

unit.

Maximum length of supply air and extract air ducts

between the ventilation unit and the air distribution

box: 5 m

■

Symmetrical layout of the supply air and extract air

ducts

■

Short runs, few bends

■

In areas where greater attenuation is required, install

one silencer (accessories) each in the supply and

extract air ducts between the air distribution box and

ventilation unit.

■

Only for plastic modular ductwork (flat/round):

–

In areas where greater attenuation is required, pro-

vide additional silencers between adjacent living

and sleeping accommodation and toilets.

–

To reduce the pressure drop in ducts, fit central ris-

ers/downpipes with EPP pipe DN 160 or DN 180

where appropriate.

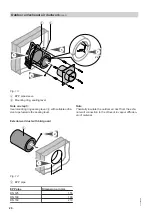

Measures against structure-borne noise

No additional measures are required if the ventilation

unit is mounted on concrete or screed floors and on

solid walls, since the Vitovent is equipped with sound-

absorbing adjustable feet and rubber washers to coun-

teract structure-borne noise transmission.

When a unit is installed on wooden ceilings, we recom-

mend additional isolation against vibration by means of

a concrete plate or anti-vibration mounts.

Never position the ventilation unit in the centre of a

ceiling if the ceiling is constructed with wooden beams.

Note

This also applies when utilising a mounting plinth

(accessories).

Air distribution/ductwork

(cont.)

5793 589 GB