First key 1,2 or 3

A

D

B

C

12

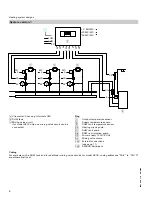

Initial Start-up

Controls and display elements

A

Heating circuit selection keys

B

User interface

ur

Space heating time program

uw

DHW heating time program

up

DHW re-circulation pump time program

j

Holiday program

tw

DHW temperature

tm

Reduced room temperature

n

Heating curve slope

N

Heating curve level

uý

Time/date

9

Standby mode

w

DHW only

rw

Heating and DHW

û

Energy saving mode

g

Party mode

/

Adjusting values

Confirmation

Information

Standard setting

C

Rotary selector ”

ts

” for ”Standard room temperature”

D

Open flap

5581

529

v1.0

08/2006