TS 21 I-HC User Manual

Vighnaharta Technologies Pvt. Ltd

Calibration process for

TS 21 I-HC PPM needs to be calibrated once in six month from support or installation team. For

calibration

, it requires calibrated gas cylinder.

Function names in the menu

1.

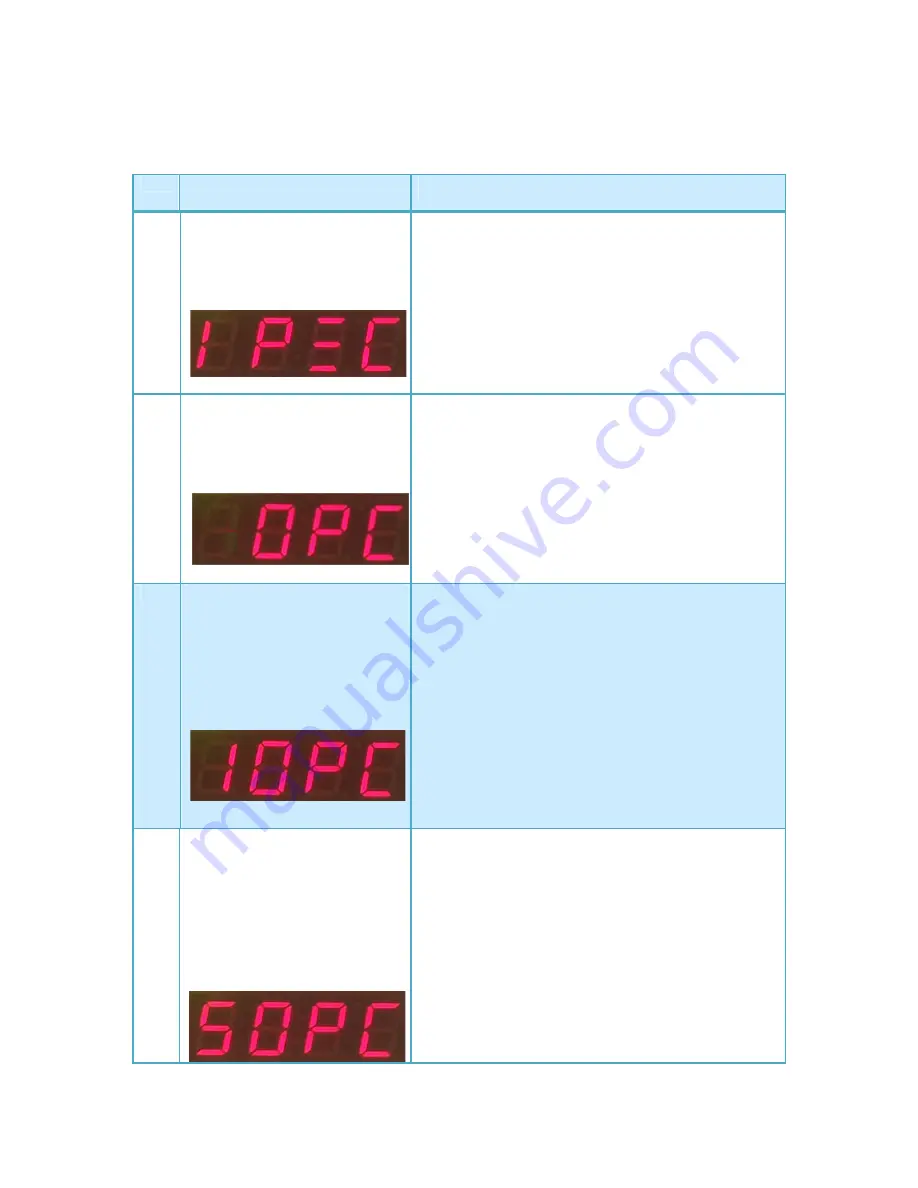

IPZC

(Input Zero Calibration)

This is a calibration function used

to calibrate sensor in clean air. It

displays raw sensor data on

seven segment display.

2.

0 PC

(Input Zero Calibration)

This is a calibration function used

to calibrate sensor in clean air. It

displays raw sensor data on

seven segment display.

3.

10PC

(10%LEL calibration)

This is a calibration function used

to calibrate sensor for 10% LEL

gas. This menu must be used

only when the unit is in clean

atmosphere. It displays raw

sensor data on seven segment

display.

3.

50PC

(50%LEL calibration)

This is a calibration function used

to calibrate sensor for 50% LEL

gas. This menu must be used

only when the unit is in clean

atmosphere. It displays raw

sensor data on seven segment

display.

ghnaharta Technologies Pvt. Ltd

Page

Calibration process for TS 21 I-HC

PPM needs to be calibrated once in six month from support or installation team. For

, it requires calibrated gas cylinder.

n names in the menu

Process Steps

This is a calibration function used

to calibrate sensor in clean air. It

displays raw sensor data on

1.

Connect a sensor at

CON4

.

2.

Preheat the sensor for minimum 30 minutes

3.

Go to menu

IPZC

.

4.

Also measure voltage at

TP8

with respect to

ground.

5.

Adjust the trim pot

R5

to get zero counts

voltage at

TP8

.

6.

Press

ENTER

key to save the setting.

7.

Press

ESCAPE

key to exit from Configuration mode

and remain in Idle or Scan mode.

This is a calibration function used

to calibrate sensor in clean air. It

displays raw sensor data on

8.

Connect a sensor at

CON4

.

9.

Preheat the sensor for minimum 30 minutes

10.

Go to menu

0 PC

.

11.

Also measure voltage at

TP8

with respect to

ground.

12.

Adjust the trim pot

R5

to get zero counts

voltage at

TP8

.

13.

Press

ENTER

key to save the setting.

14.

Press

ESCAPE

key to exit from Configuration mode

and remain in Idle or Scan mode.

This is a calibration function used

to calibrate sensor for 10% LEL

be used

only when the unit is in clean

atmosphere. It displays raw

sensor data on seven segment

1.

Connect a sensor at

CON4

.

2.

Preheat the sensor for minimum 30 minutes.

3.

Go to menu

10PC

.

4.

Use 10% LEL concentration calibration gas cylinder

and give gas to the sensor.

5.

Note down the count.

6.

Press

ENTER

key to save calibration.

Note

: Do not stop giving gas to sensor until settings

are saved.

7.

Press

ESCAPE

key to exit from Configuration mode

and remain in Idle or Scan mode.

8.

Give 10% LEL gas and check if display shows 10%

LEL. This is to confirm the calibraton.

This is a calibration function used

to calibrate sensor for 50% LEL

be used

only when the unit is in clean

atmosphere. It displays raw

sensor data on seven segment

1.

Connect a sensor at

CON4

.

2.

Preheat the sensor for minimum 30 minutes.

3.

Go to menu

50PC

.

4.

Use 50% LEL concentration calibration gas cylinder

and give gas to the sensor.

5.

Note down the count.

6.

Press

ENTER

key to save calibration.

Note

: Do not stop giving gas to sensor until settings

are saved.

15.

Press

ESCAPE

key to exit from Configuration mode

and remain in Idle or Scan mode.

16.

Give 50% LEL gas and check if display shows

LEL. This is to confirm the calibraton.

Page

12

of

19

PPM needs to be calibrated once in six month from support or installation team. For

minutes.

with respect to

to get zero counts and zero

key to exit from Configuration mode

Preheat the sensor for minimum 30 minutes.

with respect to

to get zero counts and zero

iguration mode

Preheat the sensor for minimum 30 minutes.

Use 10% LEL concentration calibration gas cylinder

o not stop giving gas to sensor until settings

key to exit from Configuration mode

Give 10% LEL gas and check if display shows 10%

minutes.

0% LEL concentration calibration gas cylinder

o not stop giving gas to sensor until settings

key to exit from Configuration mode

0% LEL gas and check if display shows 50%