SECTION TSM

845.1

ISSUE

C

PAGE 10 OF 13

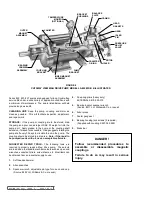

PUMP ASSEMBLY

Use a lubricant compatible with the fluid being handled when

reassembling the pump.

Inspect all parts, replacing any worn parts. Polish out any

nicks or burrs and clean all parts thoroughly. Make sure drilled

holes in rotor, shaft, orifice, balance plate and bracket are

clear. Plugged areas will cause heat buildup and destroy the

magnets. Also check the drilled passageways in the head and

idler pin to be sure they are clear.

1.

If the casing was removed from the bracket, place the

O-ring into the groove on back mounting face of casing

(side closest to the hole for the locating pin), and carefully

slide the casing onto the pilot of the bracket and install

capscrews. Install the locating pin into the casing.

2.

Place the balance plate into the casing bore with grooved

side out. Orient the groove toward the discharge port.

Push to the bottom of the casing. Line up the notch in

plate with the pin projecting through the casing bore.

3.

Insert the shaft gently into the inner bushing bore and

push through until rotor is up against the balance plate.

4.

If the old head gaskets are not reusable, refer to Gasket

Table

figure 18

. Otherwise, place all head gaskets on

the head. Proper placement of the head is achieved by

the correct number of gaskets. Improper placement will

adversely affect the operation of the pump. The Gasket

Table shows the recommended end clearance and

itemizes the content of gaskets in a set. The O-ring is the

primary seal and should be installed onto the head pilot

after the proper gaskets have been put in place.

5.

Coat the idler pin with suitable lubricant and place the

idler on the idler pin in head.

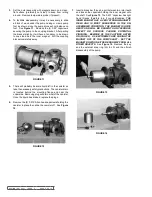

6.

The head can now be assembled on the pump. Tilt the

top of the head away from the pump slightly until the

crescent enters the inside diameter of the rotor and rotate

the idler until its teeth mesh with the rotor teeth. Line up

mark on head and casing, which were previously marked

to insure proper reassembly. Be sure idler pin, which

is offset in pump head, is positioned toward and equal

distance between port connections to allow for proper flow

of liquid through pump. Tighten the head capscrews (or

nuts onto studs in the Q size). Check the end clearance

using a feeler gage as illustrated. See

figure 20

on page

11. If end clearance is not correct, refer to section on

ADJUSTING HEAD GASKET END CLEARANCE

on

page 11.

7.

Install relief valve if provided and removed.

8.

Install the snap ring onto the shaft (not required on Q

size). Apply a lubricant to the canister O-ring and place

into the face groove in the bracket.

fIGURE 16

fIGURE 17

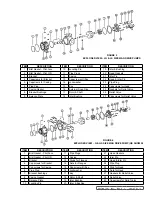

fIGURE 18

GASKET TABLE

PUMP MODEL

NORMAL

➀

END

CLEARANCE

ONE SET Of

GASKETS CONSISTS

Of THE fOLLOWING

LQ & LS-825

.008

(1) .015

(2) .007

(2) .005

Q & QS-825

.010

(1) .015

(2) .007

(3) .005

End clearances are adequate for viscosities up to 750 SSU

(SAE 20-lube oil at room temperature). Higher viscosity

liquids require additional end clearances.

As a general guideline, for viscosities between 750 and 7500

SSU (heavier lube oils) add an additional 50% of the end

clearance listed, for viscosities between 7500 and 25,000 SSU

(e.g., resins) double the amount indicated.

For specific recommendations for end clearances for viscosity

or for operating temperatures above 225ºF, check with your

Viking representative or consult the factory.

➀