SECTION TSM

685.2

ISSUE

C

PAGE 10 OF 16

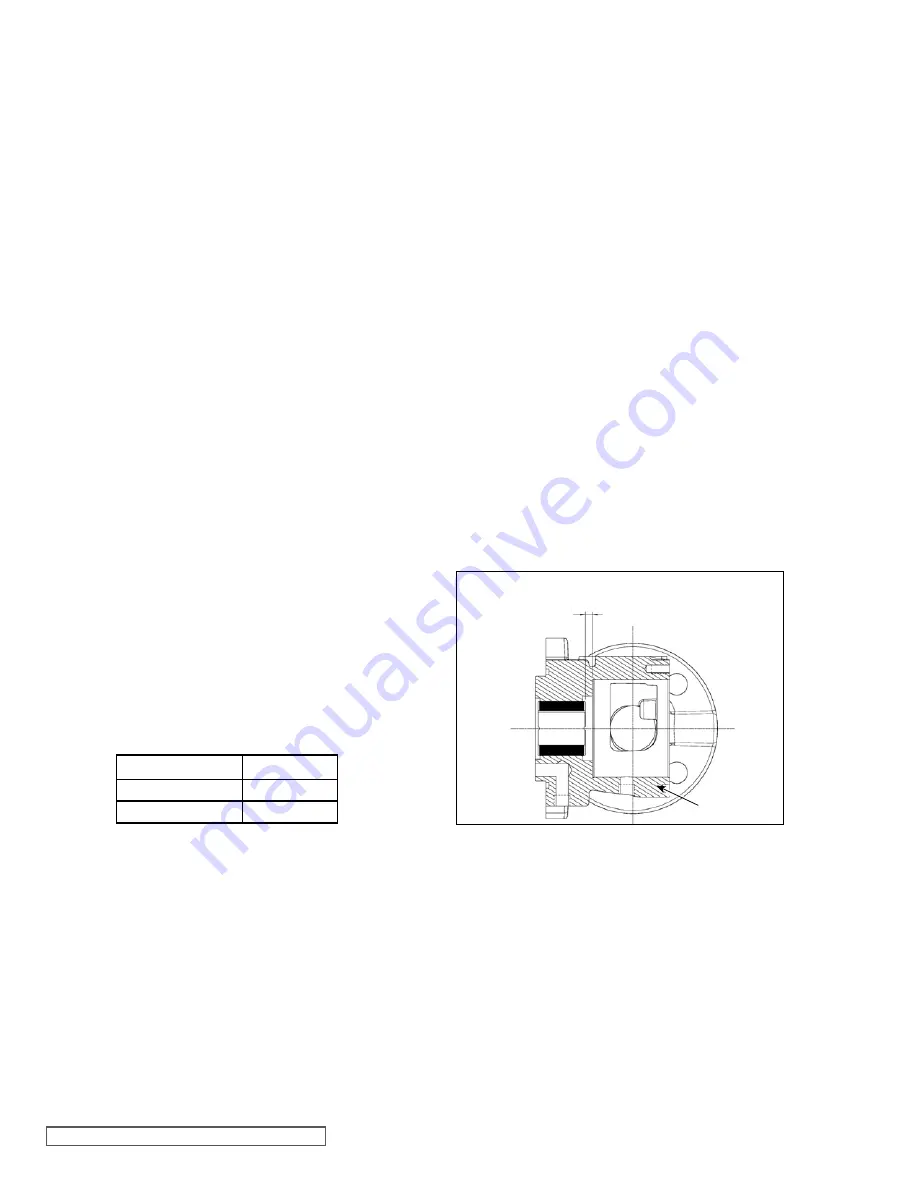

INSTALLATION Of BUSHINGS

CARBON GRAPHITE

The canister bushing

(see figure 9 on page 8)

requires a

special fixture for proper assembly so the bushing is only

sold as part of the canister assembly.

If attempting to install the carbon graphite idler or casing

bushing, extreme care must be taken to prevent breaking.

Carbon graphite is a brittle material and easily cracked.

If cracked, the bushing will quickly disintegrate. Using a

lubricant on the bushing and mating part will help facilitate

installation.

figure 15

shows the proper position of the casing bushing

after installation. This will require a special fixture for proper

position. Improper location may result in a pump with

excessive slip or requiring a large number of shims. The

additional precautions listed below must be followed for

installation:

1.

An arbor press must be used for installation.

2.

Be certain the bushing is started straight.

3.

Do not stop the pressing operation until the bushing is in

the proper position; starting and stopping will result in a

cracked bushing.

4.

After installation, check the bushing for cracks.

fIGURE 15

CASING BUSHING POSITIONING

ASSEMBLY Of PUMP

Use a suitable lubricant compatible with the fluid being

handled when reassembling the pump.

Inspect all parts, especially drilled holes in the casing (for

draining) to make sure they are not plugged. Replace any

worn parts, remove any burrs, and clean all parts before

assembling the pump.

1.

If the canister O-ring needs to be replaced, apply a

lubricant to the O-ring and place it into the O-ring groove.

If the O-ring is PTFE (derivative) encapsulated, follow

these special instructions.

ASSEMBLY

Depending on the condition of the bearings, either replace or

repack existing bearings by cleaning and packing with multi-

purpose NLGI # 2 grease. Replace the lip seals if necessary.

See figure 14, page 9

for lipseal orientation.

1.

Place the bearing housing milled-face down with cast

surface up. If the inner lip seal was removed, install with

the cup up. Install the cup of inner bearing into housing

(cup up).

2.

Slide the inner tapered roller bearing cone onto the shaft

(cone down) and then the inner spacer followed by the

outer cone (cone up).

3.

Guide shaft into the housing and into the inner lip seal.

Slide the tapered roller bearing outer cup into the housing

(cup down) and the bearing spacer collar onto shaft.

4.

Thread in the end cap until it meets the outer cup. Install

the lockwasher and locknut. Secure the end of the shaft

in a vice with padded jaws then tighten the locknut.

Tighten the end cap until there is considerable drag on

the bearings, then back off the end cap approximately

10°. Secure the end cap into position by tightening the

two set screws.

5.

Tighten the locknut again, then bend over the appropriate

lockwasher tab.

6.

Install the inboard drive key, then slide the magnet onto

the shaft. Locate the outer magnet per dimension “A”

listed below. Tighten the two setscrews to lock into

proper position.

Bearing Carrier for MD2-C Couplings

(Cont.)

.245

.242

Inch

mm

6.223

6.147

Pump Design

“A” Dim.

U.S. Inch Design

10.43 inches

Metric Design

265 mm

“C” Coupling Outer Magnet

Location Dimension

Casing