SECTION TSM

685.2

ISSUE

C

PAGE 11 OF 16

Do not

attempt to reuse a PTFE (derivative) encapsulated

O-ring if it has been removed. Immerse a new O-ring in

boiling water for a few minutes. Remove it from the water

and stretch out the O-ring so it will fit onto the casing hub

without forcing it over a sharp edge. Run hot water* over

the O-ring until it shrinks down tight onto the pilot of the

pump. Dry with compressed air.

2.

Clean the rotor and shaft so it is free of dirt, grit and other

debris and apply lubricant. Place one thrust washer onto

shaft so that the blind hole in thrust washer will line up

with the drive pin on the back of the rotor. Push the rotor

and shaft it into the casing as far as it will go.

3.

Slide the second thrust washer onto the shaft, drive hole

facing out and then install the key into the shaft.

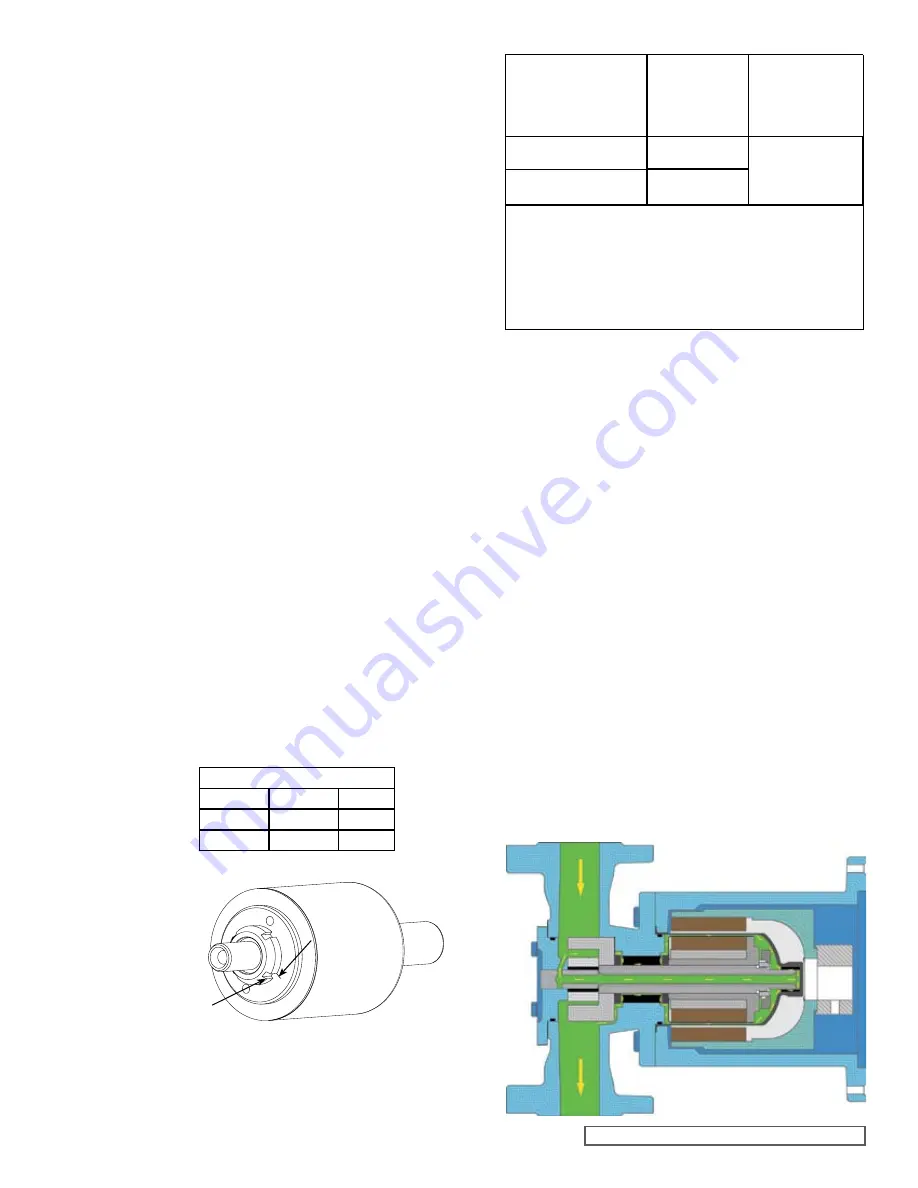

4.

Slide the inner magnet onto the shaft and engage the pin

of the magnet into the hole of the thrust washer. Install

the locknut, beveled edge out. Tighten the locknut to

the torque value given in

Table 6.

Place a mark on the

trailing edge of the locknut slot. Refer to Figure 16.

Back off the locknut until the leading edge of that same

slot lines up with the mark. This will establish the proper

clearance for the thrust washers.

5.

Place the set collar on the locknut and install the two

machine screws.

6.

If the old metal shims are not reusable or if any parts

have been replaced, operating clearances will need

to be re-established. Refer to “

ADJUSTING END

CLEARANCE” on page 13.

Otherwise, place the head

shims on the head. The proper amount of shims should

be used to provide the correct end clearance.

Table

7

gives the quantity of shims available in a gasket set

along with standard end clearance.

7.

Coat the idler pin with a suitable lubricant and place

the idler on the idler pin in head. Make sure the O-ring

for the head is installed (In the O-ring is PTFE, follow

instructions given in step 1).

8.

The head can now be assembled onto the pump. Tilt the

top of the pump head away from the pump slightly until

the crescent enters the inside diameter of the rotor and

rotate the idler until its teeth mesh with the rotor teeth.

The pump head and casing should have been marked

before disassembly to insure proper reassembly. If

not, be sure the idler pin, which is offset in the pump

head, is placed in the 12 o’clock position from the port

connections to allow for proper flow of liquid through the

pump. Install the head capscrews. Rotate the shaft to

make sure it turns freely.

9.

Follow the instructions listed for assembling the

appropriate size coupling on page 12.

PUMP ROTATION

The pump is designed to operate in either direction. Process

fluid is generally fed to the inner thrust washer and bushing

interface and then through a groove in the bushing to the

outer thrust washer. Then the fluid is pulled into the canister

bushing and back through the hollow shaft and idler pin to the

suction side of the pump. When the pump is operated in the

opposite direction, the fluid flow is reversed.

NORMAL

1

END

CLEARANCE

(inch)

SET Of HEAD

SHIMS INCLUDES

AS, AK, AL 855

0.005

(1) .007

(1) .005

(2) .002

(2) .001

KE, KKE 855

0.005

1

End Clearances are adequate for viscosities up to 2500 SSU /

540 cSt (SAE 40 lube oil at room temperature). Higher viscosities

require additional clearances. As a general rule the end clearance

is doubled for higher viscosities. For specific recommendations for

end clearance for viscosity or for operating temperatures above

225 °F (107 °C), check with your Viking representative or consult

the factory.

TABLE 7

fIGURE 17

Mark

Leading Edge of

Locknut

*Hot water makes the PTFE more pliable and allows the inner elastomer to

pull the PTFE back to the orginal size.

Locknut Torque Requirement

In-Lbs

N-m

MD2-B

60

6.8

MD2-C

80

9

TABLE 6

fIGURE 16