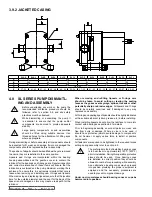

fIGURE 25

To increase the pre-load add shims to position A.

To decrease the pre-load remove Shims from position A.

See section 6.2 for pre-load settings.

POsITION a

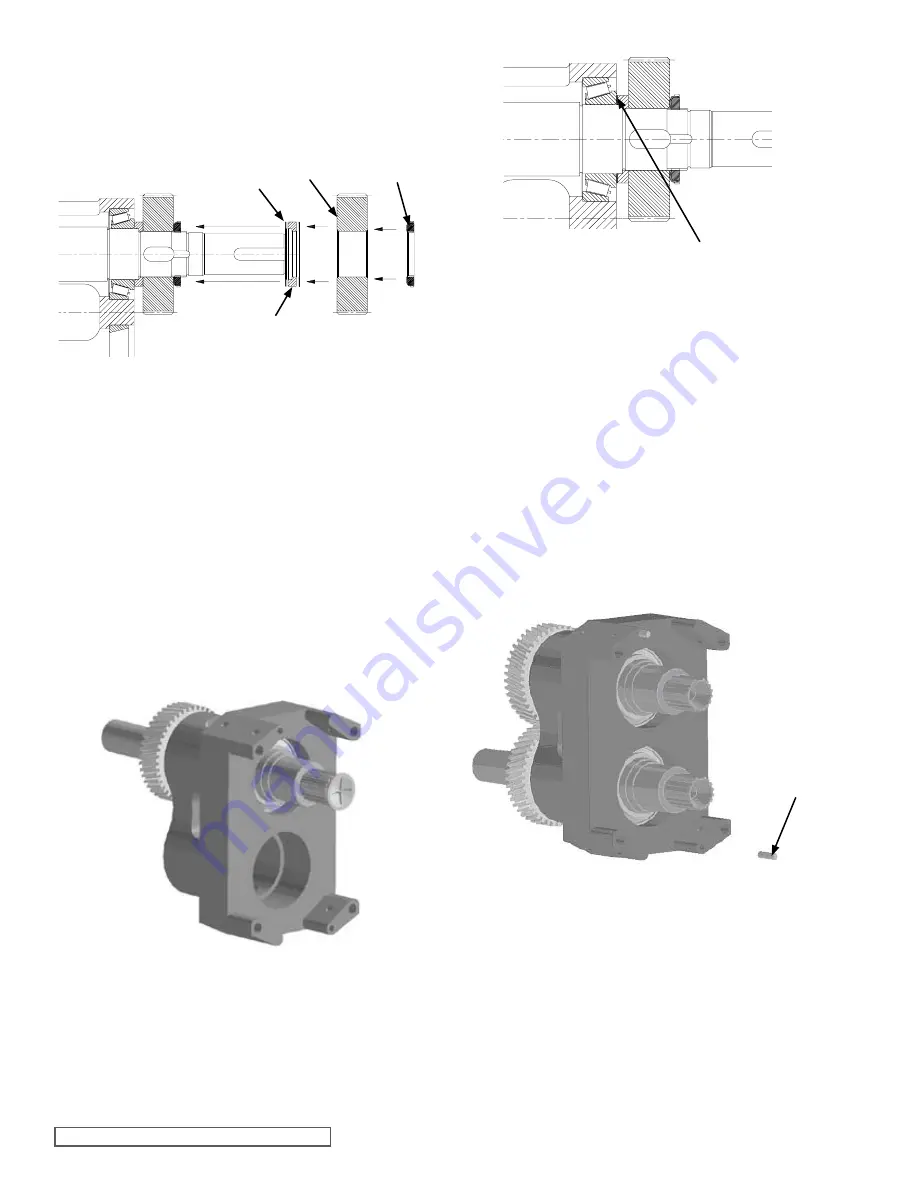

fIGURE 26

4.06

fIGURE 24

fIGURE 23

5.13

5.06

5.09

5.05

SECTION TSM 288

ISSUE

A

PAGE 14 OF 36

• Install the casing (3.01) onto the bearing housing (4.01) and

use the bolts (4.07) to secure the casing (3.01)

NOTE:

Without the gearbox cover spacers may be required to

ensure the casing is fully clamped in position

NOTE:

The pre-load must be set one shaft at a time.

When the pre-load is set remove the gear and install the gear

keys (5.07)

This procedure must be repeated for the second shaft

4.1.3 CasING assEMblY

• Install the dowels (4.06) into the bearing housing

(See Figure 26)

4.1.2 ROllING TORQUE /

PRE-lOad

Use a torque meter to check the rolling torque see section 6.2

for torque settings.

If the rolling torque is under / over the required amount add /

remove shims to adjust the pre-load to suit (See section 6.2

Fasteners & Torque Settings).

NOTE:

Rolling torque can only be set on new bearings, with no

sealing devices installed i.e. lip-seals or O-rings.

When checking the rolling torque is it important to make sure

the shaft is rotating freely, completely rotate the shaft 10 times

before checking the rolling torque.

The pre-load is set by adding or removing shims in position A

(See Figure 25).

Install 0.25 mm (0.009”) of shims (5.13) , pre-load spacer

(5.05), gear (5.06) and locknut (5.09)

NOTE:

Do not install the gear key or tab washer at this time

When setting the pre-load on the shafts note the pre-load has to

be set on individual shafts, so only install one gear at a time.