9

8

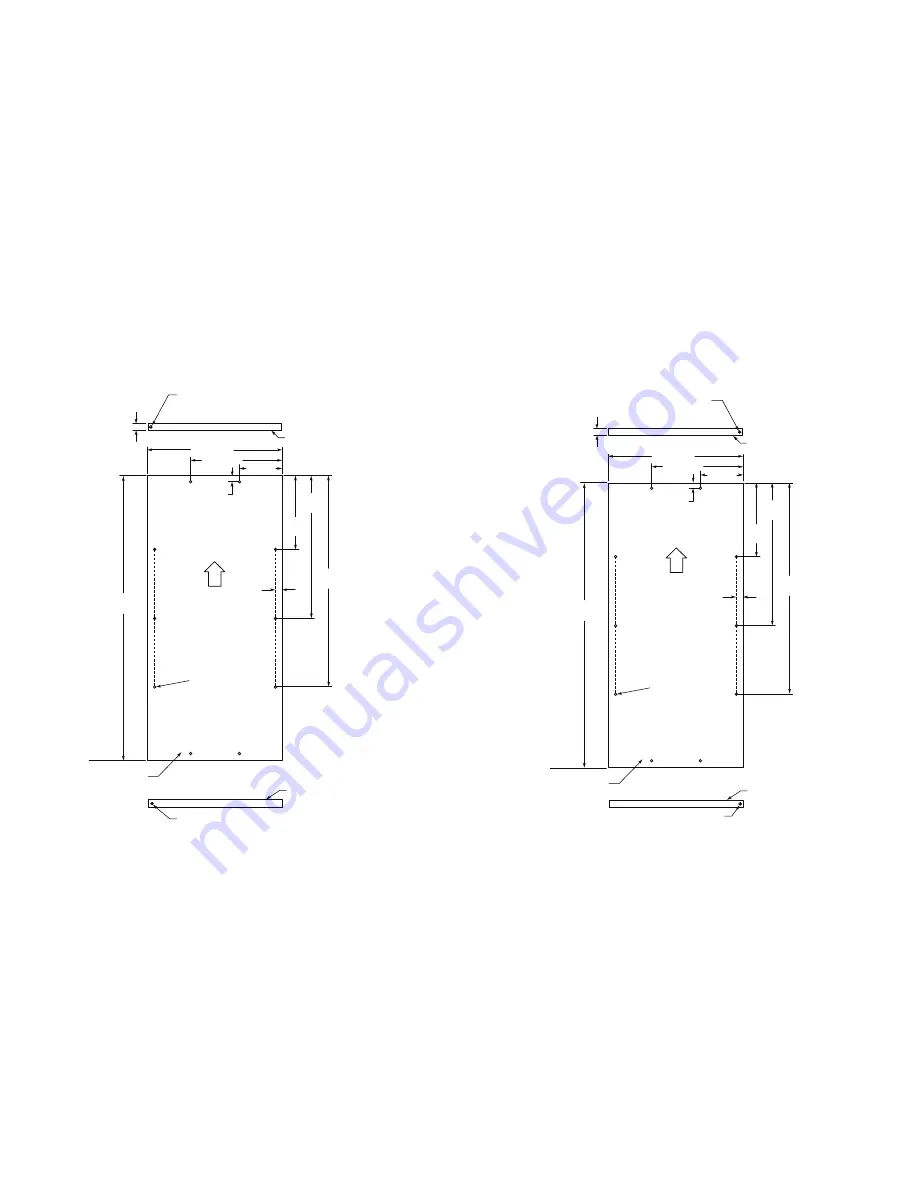

Selecting and Preparing the Wood Frame - DFIM Models

BAC

K VI

EW

OF

OVE

RLAY

PAN

EL

TOP

OF

DOOR

Pre-drilled pilot holes -

10 places

23-27/32”

(60.6 cm)

TYP

14-7/16”

(1.12 cm)

TYP

5”

(12.7 cm)

TYP

13/16”

(2.1 cm)

TYP

30-5/16”

(77.0 cm)

TYP

23/32”

(1.8 cm)

TYP

14-3/4”

(37.5 cm)

5”

(12.7 cm)

TYP

Mounting Surface

(non-face) side

Mounting Surface

(non-face) side

Mounting Surface

(non-face) side

1/4” x 3/8” deep hinge screw clearance hole. Locate and drill using

door hinge hole after the door has been aligned to the unit and when

the wood is positioned on door.

Min. 5/8”

(1.7 cm)

Max. 3/4”

(1.9 cm)

1/4” x 3/8” deep hinge screw clearance hole. Locate and drill using

door hinge hole after the door has been aligned to the unit and when

the wood is positioned on door.

8-1/8”

(20.7 cm)

TYP

FOR A 3-1/2” TOE KICK

(COVERS THE ENTIRE DOOR FRONT - LEFT HINGE)

FOR 3-1/2” TOE KICK

(COVERS THE ENTIRE DOOR FRONT - RIGHT HINGE)

Selecting and Preparing the Wood Frame - DFIM Models

BAC

K VI

EW

OF

OVE

RLAY

PAN

EL

TOP

OF

DOOR

Pre-drilled pilot holes -

10 places

23-27/32”

(60.6 cm)

TYP

14-7/16”

(1.12 cm)

TYP

5”

(12.7 cm)

TYP

13/16”

(2.1 cm)

TYP

30-5/16”

(77.0 cm)

TYP

Mounting Surface

(non-face) side

Mounting Surface

(non-face) side

1/4” x 3/8” deep hinge screw clearance hole. Locate and

drill using door hinge hole after the door has been aligned

to the unit and when the wood is positioned on door.

1/4” x 3/8” deep hinge screw clearance hole. Locate and drill

using door hinge hole after the door has been aligned to the

unit and when the wood is positioned on door.

Min. 5/8”

(1.7 cm)

Max. 3/4”

(1.9 cm)

Mounting Surface

(non-face) side

23/32”

(1.8 cm)

TYP

14-3/4”

(37.5 cm)

5”

(12.7 cm)

TYP

8-1/8”

(20.7 cm)

TYP