13

OPERATING INSTRUCTIONS

S

Se

ettttiin

ng

g tth

he

e C

Co

on

nttrro

ollss

The total available temperature range of the unit is from 40 - 43

0

F (4.4

-

- 6.1

0

C) to 64 - 66

0

F (17.8 -

18.9

0

C). The middle range on the control is approximately 55

0

F (12.8

o

C). The higher the number

selected, the cooler temperature within the unit. As with any refrigeration product, there is a slight

temperature variance at different locations within the cabinet. For example, the coolest bottles will

be in the rear of the four middle shelves. The bottles on the top two shelves will be 3 - 7

o

F warmer.

This is the warmest location. The bottles on the front of the middle four shelves will be 1 - 4

o

F warmer

than the rear of the shelves. Position your wine inventory accordingly (i.e. white wines in the cooler zones and red wines in the

warmer zones.) To start your wine cellar, use a screw driver to turn the control clockwise to the middle thermostat setting.

Once the bottles are loaded, allow at least 48 hours for the unit to stabilize before making any adjustments to the initial setting.

G

Ge

en

ne

erraall T

Tiip

pss aan

nd

d S

Su

ug

gg

ge

essttiio

on

nss

•After making a temperature adjustment, allow 24 hours for your wine cellar to reach a new temperature setting.

•The motor will start and stop often. It must do this to maintain the temperature setting.

•Unplug the wine cellar before working on anything with the electrical system.

•Exercise caution when sweeping, vacuuming, or mopping near the front of the unit. Damage to the grill and/or the

light fixture switch can occur.

INTERIOR LIGHT

The interior light allows you to view the unit’s contents. When the switch is in the “OFF” position, the light

will come on only when the door is opened. In the “ON” position, the light remains on continuously.

LIGHT TUBE REPLACEMENT

N

No

otte

e:: Please contact your Viking Range Corporation parts distributor or dealer to order new light tubes. Use only approved

replacement light tubes from your dealer or manufacturer.

DANGER

Failure to disconnect the power cord when changing the light tube may result in electrical

shock.

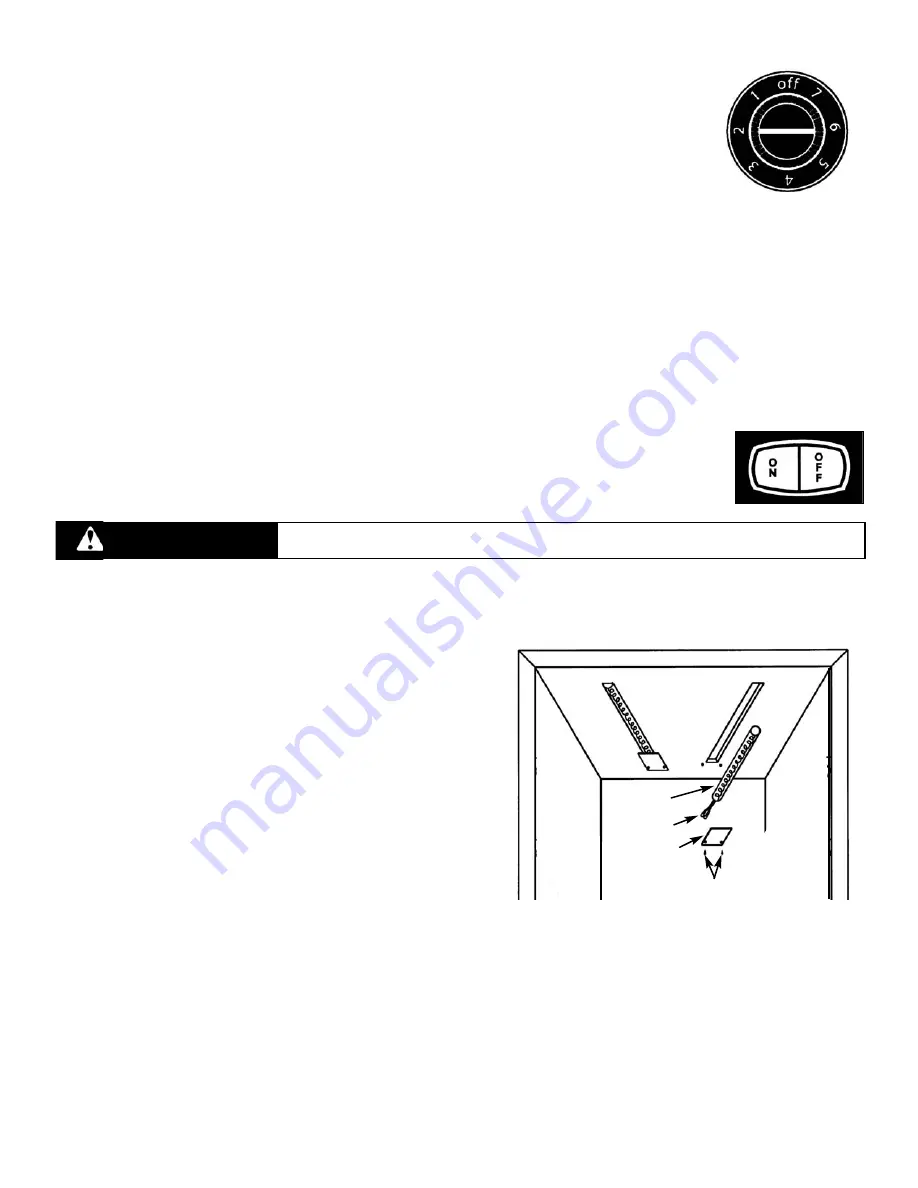

This product uses two 6-watt light tubes to illuminate the interior

of the wine cellar. The light tubes are very reliable electrical

components, but should either or both light tubes not function

properly, please call your local dealer for replacement light tubes.

To replace the light tube:

•Use a small Phillips head screwdriver to remove the two screws

holding the cover plate over the back section of the light tube.

Set the screws and cover plate aside for re-assembly later.

•Using a small flat-blade screwdriver, gently lever the front section

of the light tube down to allow it to be pulled clear of the light

housing. Disconnect the two insulated electrical connectors from

the cabinet's electrical cable and discard the old light tube.

•Reconnect the insulated electrical connector of the new light tube

to the cabinet's electrical cable connectors. Make sure they are

secure and fully inserted.

•Carefully realign the light tube's electrical terminals back into the rear of

the light enclosure channel making sure not to crimp them. Gently insert the

light tube along the length of the light enclosure channel. Press the light tube

gently into the light enclosure channel. Only a small part of the light tube should project below the ceiling of the

wine cellar. DO NOT USE A HAMMER TO FIT THE LIGHT TUBE.

•Place the light tube terminal cover plate back in its original position on the light enclosure's flange. Re-use the

original two screws to secure the cover in place. Plug the wine cellar into the electrical socket. Check to see if the

light tubes operate properly.

Light tube

Connectors

Cover plate

Screws