11

WARNING:

To avoid electrical shock which can cause severe personal injury or death,

disconnect power to refrigerator using power switch before servicing. Wires removed during

disassembly must be replaced on proper terminals to insure correct earth ground and polarization.

After servicing, reconnect power using power switch.

Charging:

NOTE:

Do not use captured or recycled

refrigerant in Viking units. Captured or

recycled refrigerant voids any warranty.

NOTE:

Charge system with exact amount

of refrigerant. See Technical Sheet or refer

to unit serial plate for correct refrigerant

charge. Inaccurately charged system will

cause future problems.

NOTE: No Access Valve are to be left on

the system after repairs are made.

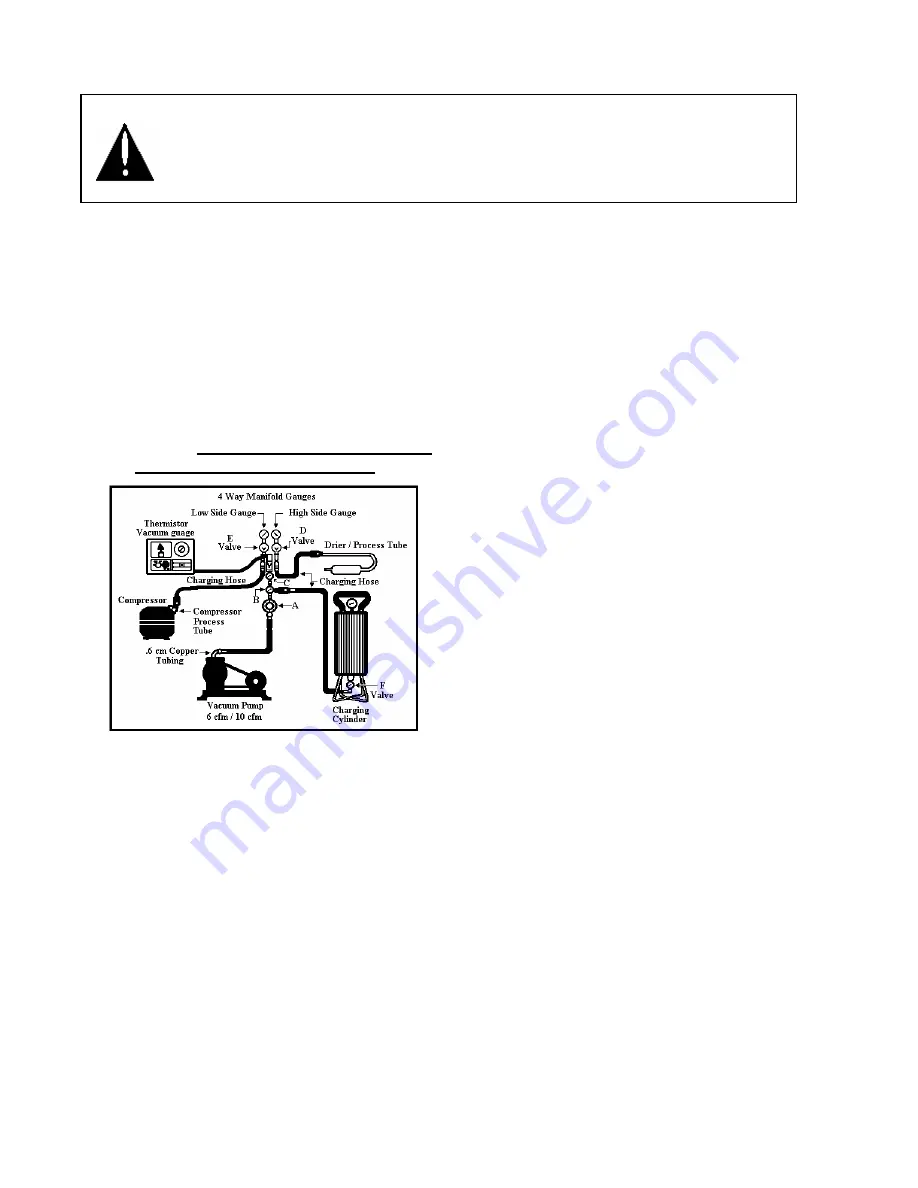

To charge system:

1.

Close valves “A” to vacuum pump

and “C” to vacuum gauge and “E” to

low side manifold gauge.

2.

Set scale on dial-a-charge for

corresponding HFC134a pressure

reading.

3.

Open valves “F” to charging cylinder

and let exact amount of refrigerant

flow from cylinder into system.

Close valve.

Low side gauge pressure should rise

shortly after opening charging cylinder

valve as system pressure equalize

through capillary tube.

If pressure does not equalize, a

restriction typically exists at

capillary/drier braze joint.

4.

If pressure equalizes, open valve “E”

to low side manifold gauge and

pinch off high side drier process

tube.

5.

Start compressor and draw remaining

refrigerant front charging hoses and

manifold into compressor through

compressor process tube.

6.

To check high side, pinch off drier

process tube. Close valve “D” to

high side gauge. If high side

pressure rises, repeat high side pinch

off and open valve “D”. repeat until

high side pinch off does not leak.

7.

Pinch off compressor tube and

remove charging hose. Braze stub

closed while compressor is opening.

8.

Disconnect power. Remove

charging hose and braze high side

drier process tube closed.

9.

Recheck for refrigerant leaks.

Refrigerant Charge

Refrigerant charge in all capillary tube

systems is critical and exact amount is

required for proper performance.

Factory charges are shown on serial

plate. Do not use refrigerant other than

shown on serial plate.

Summary of Contents for Designer DDFB304

Page 1: ...F90612...

Page 2: ...F90612 VIKING RANGE CORPORATION P O DRAWER 956 GREENWOOD MS 38930 USA...

Page 22: ...21 Wiring Schematic 30 W All Freezer...

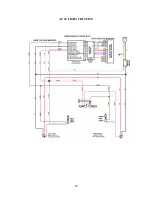

Page 23: ...22 AF 30 LIGHT CIRCUITS...

Page 24: ...23 AF 30 120V CIRCUIT...

Page 25: ...24 AF 30 SEALED SYSTEM...

Page 26: ...25 AF 30 ICEMAKER CIRCUIT...

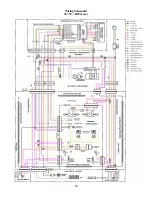

Page 27: ...26 Wiring Schematic 36 W All Freezer...

Page 28: ...27 AF 36 LIGHT CIRCUITS...

Page 29: ...28 AF 36 120V CIRCUIT...

Page 30: ...29 AF 36 SEALED SYSTEM...

Page 31: ...30 AF 36 ICEMAKER CIRCUIT...

Page 32: ...31 Wiring Schematic 30 W All Refrigerator...

Page 33: ...32 AR 30 120V INPUT AR 30 LIGHT CIRCUITS...

Page 34: ...33 AR 30 SEALED SYSTEM...

Page 35: ...34 Wiring Schematic 36 W All Refrigerator...

Page 36: ...35 AR 36 120V INPUT AR 36 LIGHT CIRCUITS...

Page 37: ...36 AR 36 SEALED SYSTEM...

Page 39: ...38 ALL MODELS New Control Boards with adapter functionality...

Page 40: ...39...

Page 48: ...47 SEALED SYSTEM...